The Fabricated Geomembrane Institute (FGI) continues to expand its technical and educational offerings, highlighting not just fabricated geomembranes but larger engineering concerns in applications that commonly incorporate these materials at some stage. Here, Dr. Tim Stark, P.E. of the University of Illinois Urbana-Champaign (UIUC) welcomes Ohio Department of Natural Resources’ W. Douglas Evans to the FGI video podcast to discuss a geosynthetic-lined slope failure at a municipal solid waste (MSW) site. They discuss the importance of understanding surface displacements, especially as they may indicate larger movement within a waste system and impact the integrity of the bottom lining system.

SLOPE FAILURE FOCUS

“State of the art came face to face with state of the practice,” Evans says, in regards to slope failure incidents that occurred after the full implementation of the Subtitle D regulations that govern waste management cell designs, from a federal perspective.

The late 1990s’ slope failure case that they discuss involved a lateral expansion project at an MSW facility. During filling of a cell, which took waste from an unlined dump and transferred it to a lined cell, tension cracks appeared in the cover soil.

RELATED: How Geosynthetics Help Design More Sustainable Landfills

“It’s very important to distinguish settlement cracks, which will not reappear in the same location in a short period of time and tension cracks, which do,” Stark says. “Tension cracks indicate slope movement which is probably resulting in movement along the bottom liner system.”

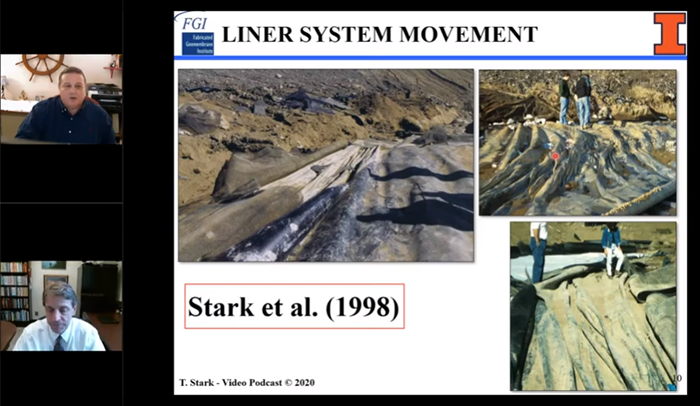

The failure of the slope and the various damage discovered in excavation (e.g., geomembrane wrinkling) suggested possible slope failure along the interface of a single-sided geonet and a smooth geomembrane or at the interface of the geomembrane and the unreinforced geosynthetic clay liner (GCL). Closer inspection also revealed movement within the unreinforced bentonite.

The video offers a number of solid takeaways, especially for designers, in regards to tension cracks, the implications of small surface movements, the challenge to designers with interim slopes, changes in waste properties, and the problem of using unreinforced GCLs without encapsulating them between geomembranes to guard against bentonite hydration issues (e.g., not hydrating globally).

“Always check the cross-section and try to find the weak link,” Stark advises. Good advice.

Watch this video and more at the Fabricated Geomembrane Institute YouTube channel and grab additional resources at www.fabricatedgeomembrane.com.