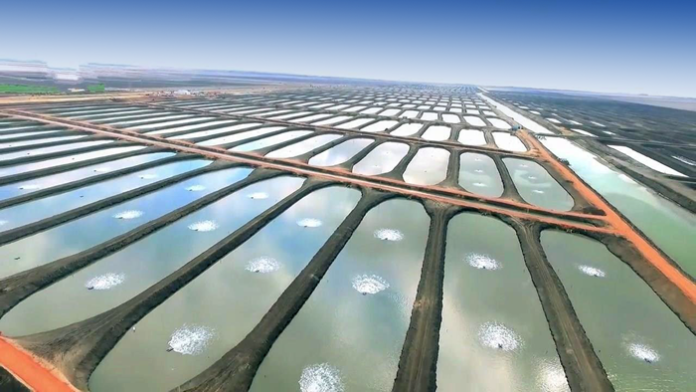

In Egypt, Phase 2 of the mega aquaculture project in East Port Said is well under way. The project was initiated by government in 2017 and includes construction of a hatchery for fish and shrimp on 4,000 acres of land. Fresh sea water will supply the fish farm via a system of canals lined by more than 3 million m2 of geosynthetics from Solmax.

“This is a valuable project that will contribute to food security, job creation, and economic growth in Egypt,” says Allan Jackson, Sales Director, EMEA. “Solmax’s geosynthetics have been used successfully in a number of aquaculture and other containment projects around the world. We are very pleased to be able to play a role in the development of this project.”

SECURING A MEGA FISH FARM

To date, 20,000 acres have been set aside for this mega project. A state agency, the Suez Canal Fish Farming and Aquaculture Company, is responsible for managing the site.

The project aims to supply up to 70% of Egypt’s domestic demand. It will, on completion, include four thousand acres of aquaculture ponds across a 7,500-acre area of sedimentation basins. Phase 2’s completion will bring the operation up to 700 ponds. A number of related structures will ensure self-sufficiency. These elements include a fish processing plant, ice plant, feed plant, and packaging plant; a veterinary and laboratory facility; and berthing facilities.

Excellence in construction will lay the foundation for success.

“The fish farm will have capacity for 20 million fish and two billion shrimp,” says Jackson. “As water continually evaporates from the ponds, keeping the ponds well supplied with fresh sea water will be critical to production, playing a crucial role in keeping fish healthy and growing and the facilities disease free. The construction of the intake channel and canals for water supply and drainage of water are thus central to ensuring the success of this project.”

The canals are built in three layers. First, there is compacted sand. Then, Solmax double-textured geomembrane is installed. Finally, concrete is added.

After the Egyptian government tested the geosynthetics, Solmax’s Egypt-based distributor (El Maseria For Insulation Company) supplied 3 million m2 of black, 1mm, double-sided textured HDPE geomembrane.

The geosynthetics help ensure the integrity of the canals, the pond system, and the environment.

“The hatchlings, fish, and shrimp that are harvested from aquaculture facilities are only as good as the quality and quantity of the water found in the ponds,” notes Jackson. “As clean water becomes more expensive to pump and transport, the need for secure water containment grows. Installing a low permeability geomembrane in the canals will help keep fresh water volumes consistent. It will also contain the waste products being drained and prevent intrusion of groundwater-borne pollutants from entering the aquaculture pond systems.

“Other beneficial qualities of the Solmax HDPE geomembranes is that they contain no additives or chemicals that can leach out or impact water quality or harm animal life. In addition, the textured surfaces of the geomembrane play a role in construction, helping with slope containment and stability through increased friction between the material and the soil, and to improve concrete adhesion at placement.”

The project took 36 months to complete, with 1.35 km2 of geosynthetics used in 2018, 1.8 km2 in 2019, and 0.3 km2 in 2020. The project was completed on time, with success leading to Solmax geomembranes being selected for related projects.

“We look forward to continuing our relationship with the Suez Canal Fish Farming and Aquaculture Company, supporting them in their effort to deliver excellence in this important project,” says Jackson.