Through high-level research, testing, and projects, the geosynthetics field is constantly building its durability record for materials and applications. HUESKER is marking another sort of durability anniversary: the success of its HaTelit asphalt reinforcement product. The first road construction to utilize the material was executed in 1971.

Roadways and runways have seen a fairly large increase in geosynthetic asphalt reinforcement in the past 10 years. The performance record of materials like HaTelit continue to show significant benefits in reduced construction time and extended service lives of the reinforced infrastructure. And, as sustainability has grown in importance for project approval, the lower CO2 impact of geosynthetics on construction works has further elevated the adoption of asphalt reinforcement.

Fifty years in the field is a milestone well worth celebrating.

HATELIT AT 50

Potholes, cracks and deformations are not only an annoyance for every car or bicycle user, they can also pose a danger. Conventional repair and rehabilitation strategies, as well-meaning as they are, have been characterized by quick, seemingly cost-effective solutions. Many of these solutions, however, wind up being more cosmetic in the long term. Reflective cracks, for example, can return quite quickly because the actual roadway deficiency may be deeper in the overall system.

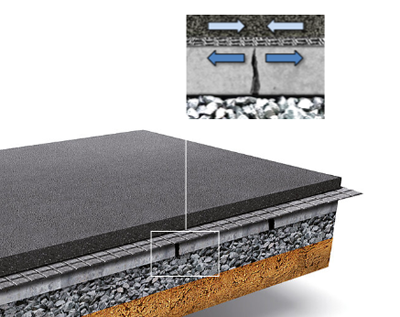

Here is where geosynthetic asphalt reinforcement excels in rehabilitation works. Instead of having to rip out and fully rebuild the entire road or runway system down through to the base, a reinforcement layer is installed to reduce stress in the system and stop the formation of road-weakening, unsafe cracks.

Materials like HaTelit are also quick and easy to install, making them a more economical and sustainable solution in the short and long term.

And, as evidenced by 50 years of installations, HaTelit asphalt rehabilitations are quite durable. The special bitumen coating (bitumen content greater than 65%) and an optimal mesh size shows a permanently high adhesive bond with the asphalt layers.

MORE GEO: Geosynthetics in Golf Course Construction

Studies have shown that even after 15 years of rehabilitation, the road is in a condition equivalent to that of a full reconstruction.

The extended service life and reduced use of material and transport not only have a positive impact on costs of up to 40% but also reduce CO2 emissions per rehabilitated lane kilometer by more than 24.3 tonnes.

Today, various types of HaTelit asphalt reinforcement are available for installation on asphalt and concrete surfaces. A particularly sustainable variant is HaTelit C eco, which consists of 100% PET recycled yarn yet performs on par with the classic HaTelit C.

Geosynthetica wishes the international HUESKER team a very happy anniversary on this achievement!

Learn more about HUESKER’s international network, geosynthetics, and engineering sectors at www.huesker.com.