|

The town of Ballina is situated on the Pacific Highway, which is the main road connecting the east coast of Australia, about 750km north of Sydney. A new motorway has been constructed for the state government agency, the Roads and Maritime Services (RMS), to bypass Ballina. The route of the bypass traverses a floodplain in which the soils comprise soft clays up to 25m depth. The clays are highly compressible and have low strength. Access and construction in these ground conditions is highly challenging. Stabilisation of embankments and construction platforms is difficult in these ground conditions. Erosion and sediment control in the floodplain, control of groundwater and drainage applications were also important. Extensive use of geosynthetics was a key component to successful delivery of this project.

Geosynthetics were used for the following purposes:

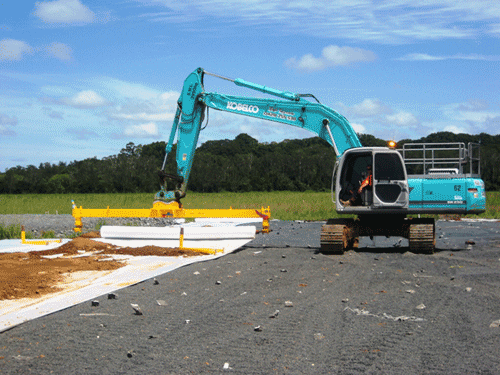

- Stabilise construction accesses and stabilize the initial layer of embankments constructed on soft clay. Geogrids were placed on top of in-situ ground and a 500mm thick layer of rockfill end dumped on top

- Stabilise temporary construction platforms for piling rigs and high capacity cranes. Multiple layers of geogrids were used in earth and rock fill to construct these platforms

- Stabilise embankments where high surcharge fills were constructed. High ultimate strength woven geosynthetics were used in multiple layers to improve short term embankment stability

- Construct temporary retaining walls using layers of fill encapsulated with high strength geosynthetics

- Mitigate effects of differential settlements on pavement in transition areas between areas of ground improvement and untreated soft clay. Layers of geogrids or geosynthetics were placed within gravel mattresses below the select material zone in areas where short wave length differential settlements might occur

- Separation of in-situ clay and earth fill from drainage layers for prefabricated vertical drains, stone columns, dynamic replacement columns and dry soil mix columns. The separation fabric helped to ensure drainage of pore water pressure was unimpeded and prevented migration of earth fill into granular construction platforms

- Stabilise soil material placed on embankment and cut batters for erosion and sediment control

- Provision of strip drains to control groundwater levels and direct runoff to collection ponds

|

Brand

|

Use

|

Quantity

|

| Tensar™ TriAx® 170 | Access, embankment, temporary works stability, mitigation of differential settlement |

305,000 m2

|

| Miragrid® 40/40 Polyester Geogrid | Access, embankment and temporary works stability |

60,320 m2 |

| Mirafi® PET 600/50 High Strength Geotextile | Surcharge fill stability |

422,500 m2

|

| bidim® Geotextile | Separation |

1,900,000 m2

|

| Megaflo® panel drain | Strip drainage |

14 km

|

| Enkamat® TRM Erosion Control Matting | Erosion control |

10,440 m2

|

|

No embankment failures occurred where high strength geosynthetics were used, despite settlements up to 6.5m and lateral displacements up to 1.0m. Trafficability and access were achieved without incident. Temporary construction platforms performed as intended with little deformation and no failure. The motorway pavement 1 year after construction is performing as intended.

The project was delivered as an Alliance contract between RMS, Leighton contractors, SMEC Australia, AECOM and Coffey Geotechnics. Design of the geosynthetics and specification for placement was performed by Coffey Geotechnics. The geosynthetics were designed generally using limit equilibrium methods but also were incorporated into detailed finite element computer simulations. The geosynthetics were installed by Leighton contractors.

This article has been provided by Coffey Geotechnics, www.coffey.com/geotechnics.

ABOUT THE AUTHORS

Dr Richard Kelly is a Principal of Coffey Geotechnics. Richard was Geotechnical Manager for the Ballina Bypass Alliance and was responsible for design of an extensive range of ground improvements including geosynthetics, vacuum consolidation, wick drains, dry soil mixing, stone columns and dynamic replacement columns. Richard also managed quality during construction and was responsible for back analysis and forward prediction demonstrating compliance with the project scope. Dr Kelly may be reached at Richard_Kelly@coffey.com.

Dr Thevaragavan Muttuvel was a lead geotechnical design engineer for the Ballina Bypass. Dr Muttuvel has subsequently worked as site geotechnical manager for the Kempsey Bypass motorway upgrade, which is another challenging project traversing soft ground. Dr Thevaragavan Muttuvel (Senior Geotechnical Engineer) may be reached at Theva_Muttuvel@coffey.com.