It has come to our attention that there have been some significant Rapid Crack Propagation (RCP) stress-cracking (SC) failures of high-density polyethylene (HDPE) geomembranes in Asia. These failures seem to reproduce the RCP “shattering” failures experienced in North America in the late 1980s.

Failures of this sort have seldom been found since the 1980s. Extensive research and testing in North America and Europe have provided the geomembrane manufacturing industry the tools to eliminate these problems. Until these new cases from Asia came to light, failures like this had not been occurring.

The author believes that these recent failures are, in fact, a result of an isolated group of manufacturers not adhering to current material standards; and that these failures are not due to the development of any new and unexpected phenomena.

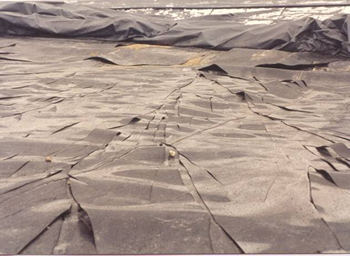

For instance, one can see a clear connection between a photo that I-CORP has from Asia this year (Photo 1) and a 1980s cracking problem in the USA (Photo 2). The USA site was a surface water runoff pond in Boise, Idaho that cracked during a rapid decrease in temperature. The failure initiated at an overheated section of a fusion seam that had been overlain by an extrusion bead.

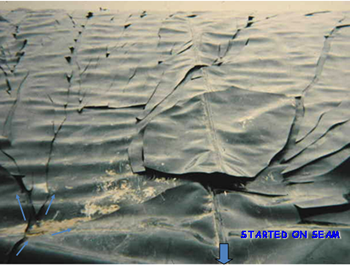

The second pair of photographs shows an Asian failure (Photo 3) compared to a more recent SC failure along and close to a seam in an unreinforced PP geomembrane on the slopes of a wastewater treatment plant (WWTP) pond (Photo 4).

The similarities are striking.

|

|

|

|

Suggestions from Asia are that the causes of these failures are local manufacturers using recycled HDPE; insufficient carbon black in the formulations; insufficient OIT (under 10 minutes); or poor resins.

The RCP shattering is spectacular but is typically initiated at Slow Crack Growth (SCG) stress cracks when they achieve a critical geometry and growth rate, such as might be caused by contraction stresses during rapidly decreasing temperatures. If the SCG can be identified and repaired during routine visual inspections, the RCP can be avoided.

However, the primary solution is to use a virgin HDPE resin with good stress-cracking resistance and with adequate thermal and photo-oxidation resistances. The GRI.GM13 standard for smooth and textured HDPE geomembranes, used internationally, requires 2% to 3% carbon black for UV protection, stress cracking resistance exceeding 300 hr in the notched constant tensile load test (ASTM D5397) and OIT times exceeding 100 min (standard OIT) and 400 min (High Pressure OIT).

Note that the ASTM D1693 bent strip stress-cracking test is no longer used.

With these simple measures in place, SCG and RCP stress-cracking failures will be absolutely minimized and will not reflect badly on geomembrane liner technology.

These cases of failure are not common, but they must be shared if we are to prevent them from further occurrences. It is unfortunate that pride often prevents the assimilation of “lessons learned” from previous failures or that our international communication efforts are not as successful as they should be.

Ian Peggs is president of I-CORP International. Visit I-CORP’s website at http://www.geosynthetic.com or write to him at icorp@geosynthetic.com.