|

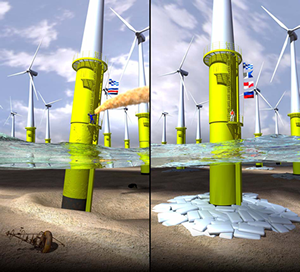

Conventional scour protections for off-shore installations are difficult to install and secure. Currents complicate foundations, creating a situation in which the installation will not be stable in the long term. Deep foundations are prohibitively expensive.

In the growing wind farm sector, the large, heavy turbines must be protected against the erosive effects normal and sudden, strong, storm-induced currents. A durable and effective alternative has been found for securing these off-shore turbines: NAUE Soft Rock®.

THE NEED

Scour protection has commonly been provided for underwater foundations by a combination of a low granular filter weighted down with stone armor. The hydraulic impact in the design has determined the amount of heavy stone needed. The overall effect of these conventional systems is to defray water forces while preserving fines. If the fines were allowed to erode, the foundation might be ever-more exposed until the stability of the structure above is threatened.

For the wind farm industry, which has grown tremendously in recent years, off-shore installations are highly attractive due to the space and the frequent, steady strong winds. Open water installations provide a steady source of alternative energy production.

The development of NAUE Soft Rock® for monopile foundation scour protection brings a durable, flexible, softer and well-established alternative technology to turbine foundation stability.

|

Soft Rock® sand containers have been used in many flood control installations. For example, more than 48,000 Soft Rock sand containers were installed in 1993 for one of Germany’s largest-ever flood barrier and scour protection installations. That installation, overseen by the German Federal Waterways Engineering and Research Institute (BAW), took place on the Eider River and helped underscore how effective mechanically bonded nonwoven geotextile containers could be. Proving their durability, the containers were even installed using a stone dumper.

In 1997, a permanent scour protection installation was carried out along the Peene River in Germany. Pile moorings were secured with 1 m3 sand containers.

ADVANTAGES

Soft Rock® is a sand-filled container made of nonwoven staple-fiber geotextiles. They provide durable, wave energy-diffusing, erosion-limiting performance but allow enough porosity that some water may dissipate through the Soft Rock container’s three-dimensional, nonwoven matrix. This energy absorbing approach allows for softer deflection and dispersal of waves.

Needle-punched Terrafix® and Secutex® nonwovens have high elongation characteristics due to the “flexible,” non-brittle fiber junctions created by the manufacturing process. Due to their superior high elongation characteristics, needle-punched nonwovens are more capable of accommodating soil irregularities, and are more resistant to puncture from imbedded stone or similar potentially damaging sources than geosynthetic products with low elongation properties, such as thermally bonded nonwovens or woven geotextiles.

|

NAUE Soft Rock® advantages for wind turbine stability include:

- Proven long-term stability in marine/saline environments

- High abrasion-resistance

- Excellent frictional behavior, including when containers are stacked

- Extremely robust against mechanical loads

- Flexibility adjusts to subsoil variations

- The rough surface of the needle-punched nonwoven geotextile contributes to absorption and adsorption of suspended substances and sand particles into the pore structure, providing additional scour protection

- 100% of the seam tensile strengths in the base geotextile can be achieved

- Prefabrication ability produces high quality in each container in the system

- Mobile sand-filling stations greatly improve site construction economics for large-scale installations

- As a soft armor solution, there is no risk of damage to the turbine and monopile foundation during NAUE Soft Rock installation, even in the case of mass installation

SUPPORTED BY RESEARCH

Though NAUE Soft Rock has been proven in numerous scour protection applications over the past 17 years, the suitability of the materials for off-shore wind turbine protection needed to be determined.

Large scale model tests were performed in the Large Wave Flume (GWK) at the Coastal Research Centre (FZK) in Hannover, Germany. Then, Germany’s first deep sea wind farm, Alpha Ventus, confirmed the results.

Alpha Ventus was constructed in 2009 and officially opened in the spring of 2010. In addition to being a fully functioning off-shore installation for clean power generation, the site also serves as a base for significant research and testing. Among its projects, Alphas Ventus has carried out tests that have verified the suitability of Soft Rock® geocontainers for foundation scour protection.

It is another example of how geosynthetics intersect and help improve all major sectors of civil and environmental engineering, from traditional road building to the latest in alternative energy facility construction.

Chris Kelsey is Geosynthetica’s editorial director. He can be reached at chris@geosynthetica.net.

LINKS

NAUE website

NAUE profile on Geosynthetica