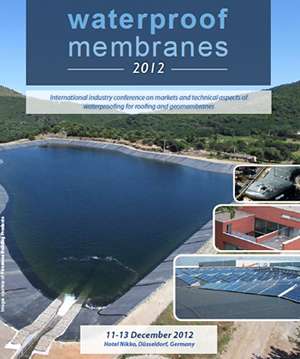

From traditional bitumen membranes in roofing, in use for thousands of years and recorded in the Hanging Gardens of Babylon, to the latest single ply synthetic materials, waterproof membranes have enabled dramatic changes in infrastructure and civil engineering. Water reservoirs, dams, landfill and road tunnels are key applications of geosynthetics. On roofs, there are many green projects underway from gardens to solar reflectors to power generation, all supported by appropriate sealing structures. The Waterproof Membranes industry is gathering at the annual AMI international conference from 11–13 December 2012 at the Hotel Nikko, Düsseldorf, Germany. The markets will be reviewed along with the latest technology.

From traditional bitumen membranes in roofing, in use for thousands of years and recorded in the Hanging Gardens of Babylon, to the latest single ply synthetic materials, waterproof membranes have enabled dramatic changes in infrastructure and civil engineering. Water reservoirs, dams, landfill and road tunnels are key applications of geosynthetics. On roofs, there are many green projects underway from gardens to solar reflectors to power generation, all supported by appropriate sealing structures. The Waterproof Membranes industry is gathering at the annual AMI international conference from 11–13 December 2012 at the Hotel Nikko, Düsseldorf, Germany. The markets will be reviewed along with the latest technology.

(Click here or on the image to the right for a look at the program.)

Construction membrane market developments will be outlined by Jon Nash, the AMI Head of Strategic Research. It is now time to look back and review the comparative ageing of the newer synthetic single-ply membranes and long-term performance. Carlisle Syntec Systems will highlight the performance of EPDM membranes, which have been in use now for over 50 years. On the testing side, the Polymer Competence Centre Leoben has carried out accelerated ageing studies on high density polyethylene membranes. The insurance industry has set its own standards for roofing and FM Approvals will describe the wind uplift and fire resistance required.

Every day advanced construction projects make use of the sealing properties of waterproof membranes. GSE Lining Technology has recently supplied sealing material for a high speed railway tunnel in Germany, and has looked at all aspects of installation.

The key focus in construction is to be more green and sustainable. HDR Engineering has installed exposed geomembranes with integrated solar energy systems as covers for landfill caps. Greening a membrane can lead to other challenges such as root and rhizome resistance for roof and wall gardens as reviewed by the Institute of Horticulture in Germany. Derbigum claims the first generation of waterproofing from vegetal materials. Waterproof membranes are often multi-purpose and Liteearth has developed a new system combining a synthetic turf capping system. In sustainable construction projects recycling is an important consideration and there is now significant recovery of waterproofing. BEVAD in Belgium has just completed a study on the feasibility of bitumen recycling.

Compounding can enhance properties such as fire resistance and oxidative stability. Minelco supplies halogen-free mineral fire retardants and Huntsman has innovative pigments to enable low carbon cool roofs with coloured roofing systems. Neptune Coatings is also examining cool roofing and comparing the performance of coatings and liquid membranes. In terms of polymer, Dow Chemical has innovative polyolefins for single-ply membrane production.

Membrane production technology is constantly under review. The leading supplier of machinery to the bituminous membrane industry, Boato International, will describe new production line technology. For single ply membranes, Davis Standard will report on new developments in production equipment. There are new reinforcements on the market too. James Dewhurst has examined the role of textiles in waterproofing and Milliken has an advanced product for membrane engineering. All efforts are wasted if the membrane is not water-tight at the joints: Leister Technologies has looked at the common mistakes in welding waterproof membranes.

The industry comes together at Waterproof Membranes 2012 to review the opportunities and issues in the international waterproofing markets. For more information, please see the event website.