In March 2014, I published “A Brief History of Geotextiles” in Land and Water Magazine. (A copy of that article may be downloaded in PDF here.) It would take a considerably long manuscript to fully detail the research, projects, events and people who have brought forth geotextiles, let alone the larger field of geosynthetics; but a welcomed result of that small article was post-publication communication with various people in the field, including Alan Ossege of Carthage Mills. His company was essential to the earliest development and push of filter fabrics into civil engineering. Here, Carthage Mills shares its story about the beginning of geosynthetic filtration materials and design. – Chris Kelsey, Editor, Geosynthetica

**

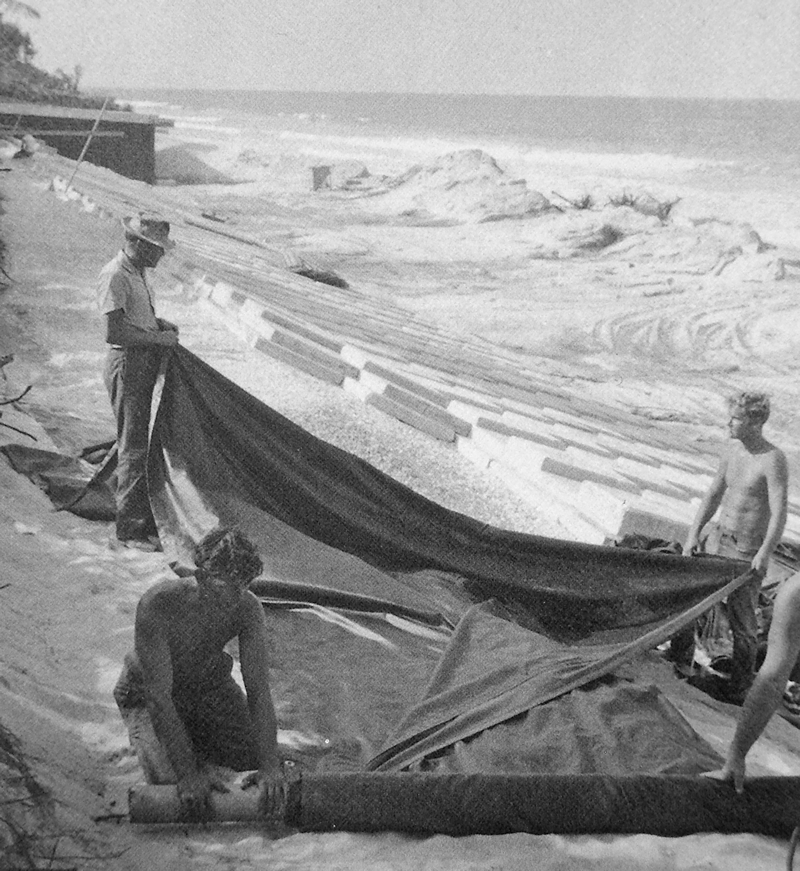

By Carthage Mills – In 1957, a tropical storm caused severe beach erosion at the Florida home of the president of Carthage Mills. Subsequently, he joined forces with engineers from the Coastal Engineering Lab at the University of Florida to protect his property against future storms. Through their exchange of ideas, they developed a tough woven synthetic filter fabric with design properties that permitted water to pass through while holding back sand and particles.

The following spring (1958), a revetment of interlocking concrete blocks was constructed using the new material in place of costlier graded granular filters. This marked the first use of a filter fabric for a waterfront structure.

EARLY EDUCATION & PROJECTS

The late Robert J. Barrett accepted the challenge to head up a commercial venture to perfect and market this new concept. Barrett set out to educate the many districts of the US Army Corps of Engineers (USACE) and consulting engineers around the world on the benefits of using these new materials.

At that time, the standard practice for shoreline erosion protection was limited to articulated concrete blocks, the deployment of large sand bags, concrete and sand-filled mattresses, concrete block mattresses, membranes, gabions, and graded granular filters.

The early years, though, were discouraging. By 1960, Carthage Mills had sold only nine projects, but momentum was building. The use spread, culminating in USACE’s 1962 agreement to construct a series of experimental projects to determine the overall effectiveness of Carthage Mills’ fabrics and innovative methods of construction.

To test these early geotextiles under what the Corps called “the most extreme conditions possible,” sites were selected along the Mississippi and St. Francis Rivers. Three years later, the Corps’ official technical reports concluded that Carthage Mills’ materials and recommended construction techniques as “superior” to every other method being employed by the Corps at that time.

The program was extended, additional sites were selected, and evaluations continued for another seven years.

ACCEPTANCE & THE MARKET ACCELERATES

Barrett continued his work with the Corps and continued to extend his education efforts further afield. In 1966, he presented at the International Conference on Coastal Engineering in Tokyo, Japan. The paper, “Use of Plastic Filters in Coastal Structures,” was a turning point for project designer and owner attitudes.

Meanwhile, Carthage Mills was still alone in its endeavors; and as late as 1967 had the only plastic filter fabrics available on the market. By this time, Carthage Mills had published the 3rd and final version of what was the world’s first “Filter Handbook,” which had been utilized by engineers and contractors worldwide for the design and construction of erosion control systems such as revetments, seawalls, jetties, channel linings, breakwaters and more.

In 1972, after ten years, the USACE Waterways Experiment Station in Vicksburg, Mississippi concluded the Corps’ experimental projects and evaluations. Their first comprehensive specification for filter fabrics, including test methods for these fabrics was issued. That specification is still used today in nearly the original form for percent open area, permeability, apparent opening size and gradient ratio to measure a fabric’s resistance to clogging.

The USACE reports and specification added considerable credibility to designs incorporating woven synthetic filter cloths.

More than 3500 projects in 49 states and 26 countries had used Carthage Mills’ materials by 1976.

Barrett was recognized as a “father of filter fabrics,” not only for his earliest work but for his interaction in additional designs, including French drains, scour protection around bridge piers, fabric-wrapped perforated pipe, and fabric-encapsulated sandcore breakwater.

NEW FRONTIERS FOR FILTER FABRICS

A major breakthrough for the use of “geotechnical fabrics” in other applications occurred in 1978 and 1979. Carthage Mills, again working with USACE, participated in the construction of a full-scale embankment test section at Pinto Pass in Mobile, Alabama. Data obtained from this study were used to develop the first effective design criteria and construction techniques for “fabric-reinforced embankments on extremely soft soils.”

The project opened a new frontier for design engineers in the potential future uses of filter fabrics.

Those first woven filter fabrics were the forerunners of the materials that have since defined the geosynthetics field. Many of those earliest installations are still in service and engineers continue to draw from those early works and add to and expand our understanding of geosynthetics.

Carthage Mills is proud to have been a key part of the early manufacturing and education efforts for such an innovative industry. And we are proud to still be an active participant and to continue working with engineers and agencies around the world to advance infrastructure. www.carthagemills.com