By Rainer Lugmayr – Passive RFID tags embedded in an asphalt geosynthetic interlayer may be coming to a road near you. The geosynthetic reduces reflective cracking while the uniquely tagged sensors provide roadway integrity and roadwork history for inspectors. The technology received an Energy Globe 2014—the world award for sustainability.

Provlies GmbH provides the RFID tag-equipped geosynthetic material, which is rolled out between a road bed and new layer of asphalt during road repair. Inspectors use an RFID interrogator unit installed on the back of their vehicles. They can pass over the tagged pavement at speeds of 30 kilometers (20 miles) per hour or more.

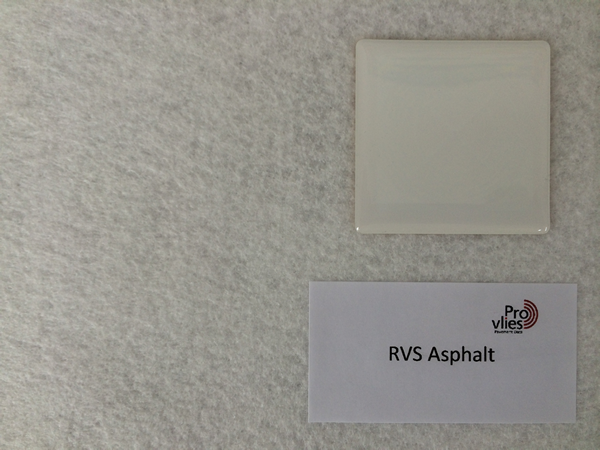

The company is currently testing the second version of its Provlies Pavement Data system with ultra-frequency (UHF) tags and readers designed specifically for the road upkeep application with a geosynthetic interlayer (GTX-N/GCO).

THE SYSTEM

The first version of the RFID-based system, installed in roadways in the United Kingdom, uses high-frequency (HF) 13.56 MHz passive RFID tags. The read rate on the HF tags is limited, however, after the installation of several centimeters of asphalt, so Provlies is now testing the UHF version in Austrian roadways.

The asphalt nonwoven geosynthetic is GTX-N / Drefon® from Fontana International GmbH. Mechanically bonded and made from 100% virgin high tenacity polypropylene fiber, the geosynthetic bonds a new asphalt surface to a road bed during roadway repaving. During road surfacing, the Provlies material is laid down on the exposed roadbed and asphalt is applied over it.

The result is significant protection against reflective cracking from the old road bed to the new surface. This prevents reflective cracking from the existing road bed into the new pavement layer.

The nonwoven asphalt overlay fabric used for this application has been available for more than 35 years. It has been approved by several road laboratory tests and a multitude of realized projects. A large history of project references is available.

The asphalt reinforcement also acts as a SAMI (stress absorbing membrane interlayer) between the two layers. The stress relief is an essential mechanism of the system and helps prolong the new pavement’s service life.

TALKING ROADWAYS

Provlies engineers have developed the Provlies RVS Asphalt products with the vision to create a smart geosynthetic which is able to talk to road maintenance staff. Typically, upon over passing roadways, inspectors frequently stop to examine a particular section. If they require information regarding the most recent surface work – such as when, and how it was performed, and with what materials – the inspectors must call back to the office or read through paperwork they carry with them. That paperwork can be sketchy or difficult to locate. It takes time and can lead to confusion, putting roadwork managers in the position of resurfacing roads without all available information about what has previously transpired at the location.

Provlies began providing its RFID solution in 2012 to a number of road authorities, with tags being installed on road beds at intervals of approximately every 150 meters. Each tag is encoded with a unique ID number that links to data about the road’s resurfacing history. Provlies can commission these tags itself or let the user do it, by using a handheld device to read each tag as it is installed. The data can be input as resurfacing takes place, with the asphalt compaction pressure and the date and exact location being recorded. That data is stored by the user, such as on their own computer or server. Provlies provides the user not only with the tags and readers, but also the middleware that links each tag read back to the user’s own road maintenance-software system.

The RFID reader is installed on the trailer hitch at the back of an inspector’s vehicle. The interrogator captures the unique ID number, forwarding that data to a laptop or tablet computer in the vehicle either via a cabled connection or Bluetooth. Inspectors typically travel in groups of two—one to drive, one to use the computer. As the inspection vehicle passes over tags, tag data can be transmitted from computer to a server and display the history of the roadway where the tags are embedded.

In this way, remote access to roadwork histories are available quickly at any location with the embedded RFID tags.

The UHF version, which is being tested in Austria, includes EPC Gen 2 tags that can be read at a greater speed by vehicle-mounted readers. The UHF reader includes an antenna that was angled to lengthen the amount of time during which a reader passing over the tag at high speed can read it. The testing has been underway since summer 2012 and the results have been good to date.

Provlies has been granted a patent on the technology in Europe as well as in the United States and South Africa which are the regions that the company will initially target while marketing the solution.

Rainer Lugmayr is CEO of Provlies GmbH, www.provlies.com. For information on Drefon® geosynthetics, visit Fontana International’s website, www.fontana-international.com.