In the April 2015 issue of Irrigation Leader, North Carolina-based HUESKER inc.’s CEO Sven Schröer was interviewed for the publication’s “Business Leaders” section. The interview, which begins on Page 28 of the issue, provides a nice introduction to the importance of geosynthetics in agricultural water security.

READ THE INTERVIEW (PDF)

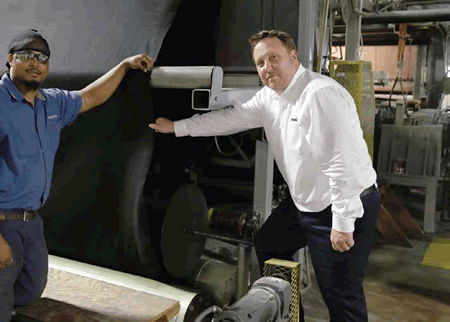

Schröer’s background is ideal here. He has worked in geosynthetics nearly 15 years, having long served at HUESKER international headquarters in Germany before moving to head up US manufacturing and operations in 2014. And, he grew up in a farming family. These experiences have given him a strong eye on innovation and response to the market from the geosynthetics side and a deep understanding of the customer on the personal experience side.

“We take a long-term view of things,” he says in the interview. “We try to come up with smart and sustainable solutions for our customers.”

Among the paths the company is advancing on is continued investment in solutions for the agriculture market, which involves strong support of water conservation efforts.

“We have been supplying the irrigation districts for more than 10 years with great solutions to address water conservation,” Schröer says. “Huesker’s canal liners are American made, durable, flexible, and they have a proven record.”

The interview with Irrigation Leader was conducted by the magazine’s editor-in-chief Kris Polly.

AGRICULTURAL WATER SECURITY

Western irrigation districts in the United States, in particular, are concerned with water conservation. California, and its massive agriculture sector, has experienced deepening drought cycles. Nevada has seen alarming drops in its supply. And various other states have struggled to stem water loss due to seepage, a loss rate concern that has been compounded by lower snow melt from the mountains.

A number of geosynthetic-related solutions have been incorporated into the wide-scale water saving efforts. Floating covers have been used on municipal water reservoirs, for examples. With irrigation canals, geosynthetic lining systems have been tapped.

HUESKER’s Canal3® product is a great example. Canal3® is a multi-layer geosynthetic composite membrane. The unique product features a long-term performance polyethylene membrane that is sandwiched between two durable nonwoven layers. The product’s outer layers provide protection of the inner membrane and enhanced frictional characteristics for secure installation, including on steeper slopes. The nonwoven protection also enables the liner to be exposed, covered with soil, or coated in shotcrete.

An extensive, 10-year study by the US Bureau of Reclamation (1992 – 2002) found a substantial, beneficial impact of geosynthetic lining systems on the value and service lives of irrigation canals.

Important for agricultural water security, the use of geosynthetics in water conservation is not limited to large-scale irrigation district canals.

Large and small farms can directly implement geosynthetics too for irrigation and general water supply security, as well as basic operational efficiency and soil conservation.

Erosion of soils on farms can impair access for heavy equipment (delivery and shipping trucks, tractors, field equipment). Impairments on that level can be costly, as they must be remedied before operations can continue at a full and effective level.

Also, eroding soil, such as on access roads or in animal feeding and water-access zones, can impair water quality to open sources on site.

Here, simple solutions such as the installation of durable nonwoven separation geotextiles can play a large role for farms of all scales.

Huesker recently shared an example of this on its Huesker North America Facebook page. At Cherryhill, North Carolina-located Pecan Ridge Farm, owner Steven Gunnell has used Ultimat® 80 and Ultimat® 120 to provide long-term stability to key access points on the beef, cattle, and crop harvesting farm. Covered by a standard layer of 6 in. of gravel, the nonwoven geotextile separation layer has prevented the mixing of fines and road rutting along the tractor trail routes. These access points are essential for the delivery of new animals, pick up of animals by processing facilities, and frequent delivery of feed. Even in rainy seasons, the geosynthetic-supported unpaved road is passable.

The farm also incorporated the same geotextile solution to stabilize soils around a new water tank installation used to support the cow side of the farm’s operation.

**

Learn more about HUESKER’s work in agriculture, water security, and other geosynthetic applications (e.g., reinforcement, transporation, and MSE walls) at www.huesker.com.