Earlier this year, Dr. Gary Fowmes received a £125,000 (USD $190,000) grant to continue research into the use of 3D printing in the design and performance of geosynthetic materials. Dr. Fowmes is a Lecturer in Engineering Geology at Loughborough University’s School of Civil and Building Engineering and the Chairman of the United Kingdom Chapter of the International Geosynthetics Society (IGS UK).

Geosynthetica’s Editor Chris Kelsey interviewed Dr. Fowmes online.

How and when did you get into 3D printing investigations with geosynthetic materials?

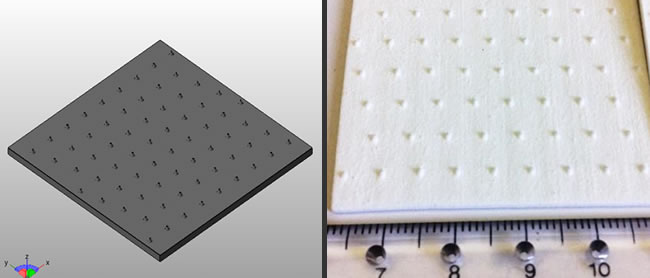

My main research interest has always been around geosynthetic interfaces, and we are very interested in working out how the stresses and loads are distributed along an interface. As part of this, we wanted to develop new texturing patterns to see if we could improve peak shear strength and reduce post peak strength loss. 3D printing seemed a logical way of rapidly prototyping geometries.

How did your earlier investigations into with 3D printing influence this latest round of research?

The School of Civil and Building Engineering at Loughborough has, for some years, been 3D printing with concrete. As part of this, there were investigations into the inclusion of polymeric reinforcement. The novel application of 3D printing in this area was really the inspiration for applying it to research of geosynthetic materials.

What, for you, have been the more interesting revelations to date?

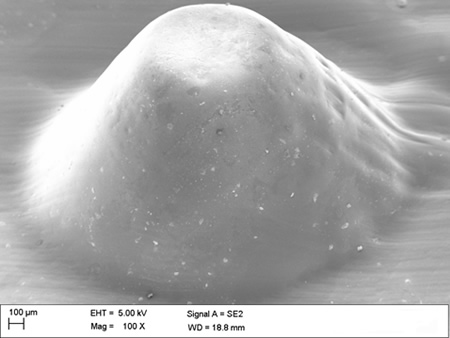

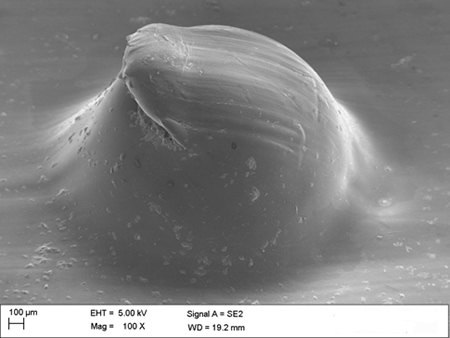

The work to date has fallen into two areas. The first has been to use scanning electron microscopes to study geosynthetic interfaces before and after shearing has taken place. We have developed a much better fundamental understanding of how load is taken and why post peak strength loss occurs. The microscopic damage to the surfaces we observed was quite a revelation, as you simply cannot see this with the naked eye.

The second area has been looking at the 3D printing itself. One of the biggest revelations has been the need to understand the polymeric composition and structure of the geosynthetics so that we can print materials that are close analogies to the geosynthetic behavior. Moreover, our investigations to date have yielded some area of improvement for the distribution of stresses at the interface, and these should give us positive benefits in interface shear strength.

Which geosynthetic materials seem most likely to benefit from the technology?

I can see 3D printing giving designers and manufacturers greater freedom to experiment on a variety of geosynthetic types. Examples such as geogrid geometries could be investigated for improved soil interaction or geocomposite drainage cores could be optimized for flow performance. What we need to remember is that the prototypes are an analogy of the geosynthetic; they may not have the same polymeric structure; therefore, there are limitations, but 3D printing remains a powerful research tool.

Is another phase of research likely for your group, or will the next additions to this body of work come from other labs or departments that look to build upon your contributions?

We have a number of other aspects of geosynthetic interfaces we’d like to explore using both the analytical and printing techniques developed as part of this project; but, we’d also like to see wider application and innovative use of this platform technology across the sector.

**

We thank Dr. Fowmes for sharing his time and insight. Learn more about Loughborough University’s Civil and Engineering Building Department at www.lboro.ac.uk/departments/abce/.