In August, Dr. Ian D. Peggs, P.E. wrote about the strong potential for graphene in geosynthetics. Layers of graphene could give materials strength exceeding steel, enable self-repairing qualities, and impart an electrical conductivity greater than copper.

In August, Dr. Ian D. Peggs, P.E. wrote about the strong potential for graphene in geosynthetics. Layers of graphene could give materials strength exceeding steel, enable self-repairing qualities, and impart an electrical conductivity greater than copper.

“Nanogeocomposites,” Peggs wrote, “are the wave of the future.”

Cambridge University may help make that ambitious prediction come to light.

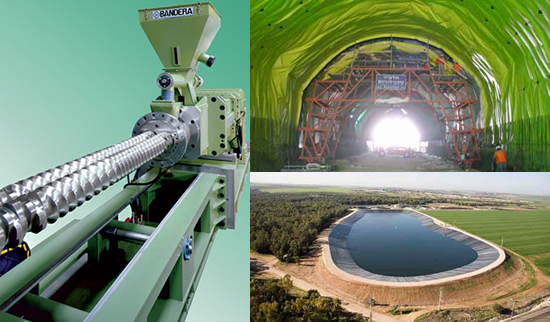

The Cambridge Graphene Centre (CGC) hosted a “Technology Days” event last week. There, in its technology showcase, key manufacturing equipment was included, such as extrusion instruments used in the production of geosynthetics.

Bandera spa is one of the companies now working with the CGC on plastics extrusion lines for substrate film and sheet applications. In a release about its involvement, Bandera noted that its work with graphene and extrusion has resulted in “industrial production output up to several tons per hour and dimensions up to 22 m for agricultural applications and 3 m for packaging, converting, printing, lamination or up to 8.5 m for waterproof systems, with multilayer (3 to 9) structure.”

The CGC, as part of its mission, cultivates joint industrial-academic projects to promote innovation.

Cambridge Graphene Centre Potential

Part of the new initiative with the CGC and extrusion machinery makers will be to develop implementable applications that incorporate graphene. This includes working with various polymers in extrusion. Pellitization of new composites and enhancement of existing products are being evaluated.

Bandera is a good partner for this research. With a background in industrial, agricultural, geomembrane, and other sectors, it will provide the geotechnical community with a familiar voice in the research. With ready solutions the goal, graphene could enter the field sooner than previously expected.

Bandera also supports an extrusion experimentation facility at its Busto Arsizio, Italy headquarters, enabling additional R&D work on this project beyond Cambridge.

Other sectors that may soon benefit, according to the manufacturer, are solar energy panels. Bandera has secured a patent for a photovoltatic plastic solution enhanced with graphene.

“The extreme multifaceted graphene properties (conductivity, transparency, barrier, strength, etc.) make it an important candidate as an additive in plastic multilayer products,” said the company on announcing its partnership with the CGC.

A New Approach

With the CGC, a new “Extruding Future Plastics Now” laboratory is being established for the creation of prototypes.

A large range of industry members are also part of the CGC’s on-going investigations—e.g., Dow—so with Bandera contributing to the innovation campaign we just might see the types of geosynthetic enhancements that Dr. Peggs identified:

- Thermal conductivity: heat removal

- Electrical conductivity: geomembranes, geotextiles, geogrids

- Hydrophilic performance

- Hydrophobic performance

- Antimicrobial performance: geotextile filter clogging prevention

- Strength with weight reduction

- Strength with ductility

- Sense: stress, temperature, moisture

- Water purification

- Precipitation from solutions

- De-watering

- Water stabilization

- Big data collection/interpretation

- Self-sealing in the presence of carbon

LINKS