A few years ago, I had the opportunity to interview Dr. Rajib Mallick of Worcester Polytechnic Institute (WPI) who was about to deliver multiple papers at the annual TRB conference. One of his contributions focused on climate change and geosynthetic-reinforced chip seal (GRCS). Here, we revisit that interview as the TRB 2020 nears its conclusion. Also, January 15 is Pothole Day. We felt that made it an especially fine time to consider roadway integrity. – Chris Kelsey

GEOSYNTHETICA: We hear a lot about climate change in regards to carbon footprints, water resources, coastal engineering. How is climate change research influencing transportation engineering?

MALLICK: In a big way. For example, flooding impacts roads in multiple ways. Flooding is an extreme event, but predictions are that rainfall will increase in certain areas. Low-lying coastal areas will see more hurricanes and more intense hurricanes. Category 3 and up will cause flooding. Those events can cut off areas and cause a more rapid deterioration of the infrastructure.

Pavements that were designed and constructed to last 20 years will last for 10 or 12 years, which has a huge impact on the kind of investment you have to make again and again.

You have to make these pavement systems resilient so they are more resistant to the impacts of climate change.

Another example is temperature. If temperatures rise, New Hampshire’s climate might slide down to a zone more like Virginia. Now, you design roads to sustain a specific maximum temperature that you expect in a location. The way the codes are written you look at the last 30 or 40 years of data and take the average and the standard deviation; and you expect the same to happen in the next 100 years. But, research is telling us that won’t happen. It will be really bad or just bad if we don’t cut down carbon emissions.

How much will we be impacted in different regions? What will we do to minimize risk?

MORE FROM MALLICK: Unsaturated Analysis of Water Flow in Granular Layers of Inundated Pavements

GEOSYNTHETICA: So climate change forecasting might need to be part of how we plan pavement systems?

MALLICK: The main hindrance is that there’s a lot of variability in climate change predictions. Weather patterns are predicted by a number of models, and you take the average, and you predict it will storm tomorrow afternoon or something like that.

With climate change, you make predictions in the same way, but there is wide variation between the predictions given by different models. Ultimately, it becomes risk analysis. How much risk are you going to take if you say this pavement will last 15 or 20 years?

GEOSYNTHETICA: Let’s talk about the geosynthetic reinforced chip seal (GRCS) you presented at TRB [in 2016]. Is it connected to climate change? And what differentiates this research from other geosynthetic-reinforced pavement studies?

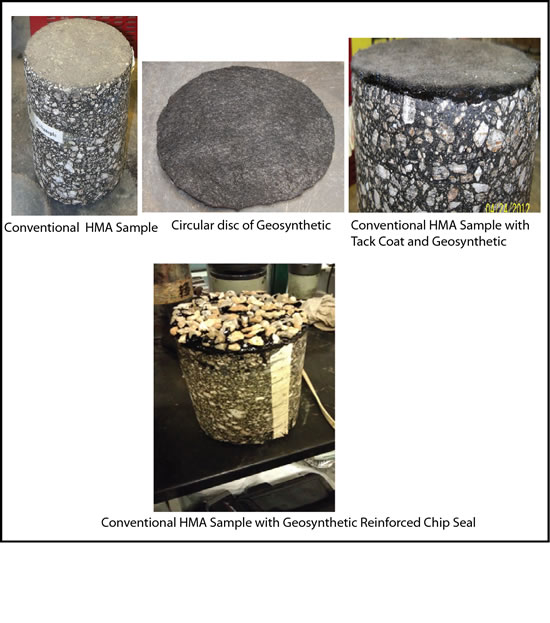

MALLICK: As you know, geosynthetics have been used for a long time in the base course and subgrade layers to prevent fines from mixing and provide reinforcement against roadway fatigue and rutting. But geosynthetics are also used closer to the surface as an interlayer, a stress-absorbing layer.

With upper layer usage, when you a have movement due to thermal reasons, expansion, for example, those movements get absorbed. You don’t have reflective cracking occurring as it would if you did not have the geosynthetic.

In 2009, we did a study for NSF to look at harvesting heat energy from pavements. We looked at the concept of putting pipes under the pavement; if a pavement gets very hot, you can flow water or any kind of liquid and extra heat energy, thereby cooling the pavement. We found that while cooling pavements in this way is a nice idea, a more practical idea for now is not cooling pavement but just have cooler pavements. Most people try to address fatigue and rutting by tweaking the materials. They put in polymers and different types of material, or they make pavement thicker. But if we can keep the pavement cooler, if it can keep the temperature lower, especially in regions with higher temperature, it would give us a lot of benefits. We can reduce the rutting potential, which is activated by temperature in asphalt pavements. We can reduce the potential of oxidative aging. Asphalt ages because of exposure to the atmosphere. So how can we reduce the temperature?

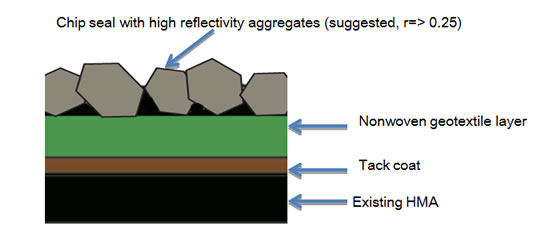

We have started our research with geosynthetics using Petromat. We put it on the asphalt and saturate it with the asphalt. On top of that, we put chip seal. The chip seal aggregates are a light color, so they have a higher reflectivity compared to dark aggregates. That serves two purposes. One, the geosynthetic and the asphalt works as an insulator. Both of them have a similar thermal conductivity: 0.11 W/m K. Compare that to copper, which is more than 300 W/m K. So, heat does not travel through the geosynthetic/asphalt layer fast.

If you have highly reflective aggregate, it reflects more of the sun’s rays so you have less solar energy absorption. So if we put this layer on top of the pavement, below that, where you have the actual pavement, the geosynthetic-reinforced chip seal reduces temperature and a whole lot of “disease” in the pavement, if I may say so.

We invest billions in pavements: Why not protect them with systems like this geosynthetic reinforced chip seal?

Also, if you have an asphalt-saturated geosynthetic layer, it reduces the permeability, the flow of water, significantly. That’s a fact. It’s a protective layer that can reduce not just all temperature-related ailments but moisture-related distresses.

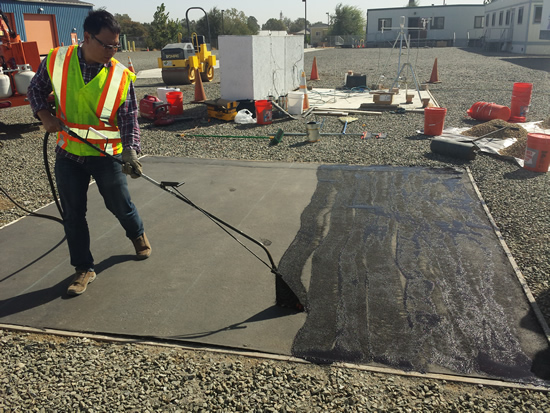

We started our research with modeling and small-scale experiments in the lab, and then in a parking lot with actual solar radiation, and then we built a test section 12 feet by 12 feet at the University of California – Davis.

GEOSYNTHETICA: Why UC Davis?

MALLICK: They have a pavement testing area with all the weather testing stations. And we had our installation side by side with other installations. We monitored it for a year with all the temperature data. What we found out is there is a significant reduction of maximum temperature throughout the year from the geosynthetic-reinforced chip seal. As the temperature rose, the difference between the conventional section and the GRCS section actually increased. Essentially, you have more performance benefits with this approach when you have a warmer climate.

So that’s where we are now. We’ve done this since 2010 without any funding, by the way. It’s been completely in-house.

The Asphalt Interlayer Association has been helpful and supportive in giving us some materials, and we earlier obtained the geosynthetic from Propex.

This is a design and product combination that has tremendous benefits but which has not yet been utilized.

GEOSYNTHETICA: Does reinforcing the surface level at the chip seal change the pavement system thickness?

MALLICK: I expect it to reduce the amount of aggregate needed in the system, and I’m working on showing that. Past studies have shown, as you know, that geosynthetics can reduce aggregate need and fatigue and rutting by 30 to 40%. I expect the same thing here.

GEOSYNTHETICA: Is this system applicable to all types of climates?

MALLICK: It’s an insulator, as far as the geosynthetic is concerned. It should work equally well in cooler climates. The reflective chip seal, though, is functional only for more sun-drenched regions. At this time, there are more benefits for roads in warmer temperatures.

RELATED: Assessment of Historical Army Airfield Pavement Condition Data

GEOSYNTHETICA: How common is this type of aggregate albedo for roadway chip seal? It seems more like what is used in roofing for heat island reduction.

MALLICK: Typically we do not use this type of aggregate in roads. We use what we have. Chip aggregates have pretty uniform sizes and typically are not selected for reflectivity, or albedo, as you say. This will be a unique requirement—but this kind of aggregate can be found in various parts of the country. They aren’t hard to find. And there are ways to quantify the reflectivity for selection.

The reflectivity of new asphalt is something like 0.08, so 8% of the sun’s rays are being reflected and 92% absorbed. Compare that to what we are saying: use an aggregate of at least 0.2—20% being reflected.

If you look at asphalt, it will have 0.08 but over time will lighten and become more like 0.1. Concrete starts out at 0.3, 0.29, 0.28, but then becomes gray as it degrades. Concrete has some other problems, though, like temperature differential between the top and bottom. That can lead to distresses and cracking.

Reflectivity, though, is generally not considered in regular design; but people are looking at it now. Iowa State is doing a lot of work. Arizona State is doing a lot of work. National Center for Asphalt Technology at Auburn University is doing a lot of work. They are looking at how to quantify and characterize aggregates in terms of their contributions to heat development.

The main problem is that if you use a conventional hot mix asphalt, no matter what you do with the system, you cover it with asphalt and, thus, turn everything black. It absorbs more heat. But with GRCS, you have a way to leave lighter colored aggregate exposed. Even when you embed the chip seal 70% or so in the asphalt, you still have 30% exposed.

That makes a big difference.

**

More about Dr. Mallick’s research and field contributions can be found on his WPI faculty page.

[adsanity id=”96962″ align=”alignnone”/]