The recent increase in discussion on finer points to geomembrane installations (e.g., managing geomembrane wrinkling) has us revisiting stories on other significant points regarding geomembrane system performance. Here, we look at an article authored by Andrew Plowman (Varicore) about the importance of proper drainage and venting design and how it impacts the integrity of geosynthetic containment systems. – Chris Kelsey, Editor

**

By Andrew Plowman – The quality of geosynthetic containment systems continues to increase. Manufacturers enhance and extend geomembrane and GCL performance while installers and CQA professionals elevate on site best practices. Drainage and venting materials, though, must not be overlooked in the success of these installations. Drainage materials are vital to the integrity of many lining systems, including waste management, wastewater and industrial ponds, and other common containment installations.

The concept of draining/venting under synthetic liners is nothing new, but it is an area in which significant innovation is occurring, just as with liners.

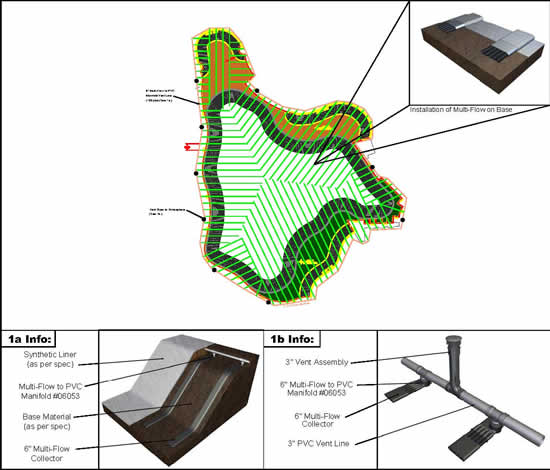

The Multi-Flow Leak Detection Vent System (LDVS) from Varicore is a good example. This geotextile-wrapped polymeric core geocomposite utilizes a time-tested product design and adds to it modularity and scalability to adapt to different project sizes and installation shapes. The product profile has rounded edges. This minimizes friction and stress points on a liner. It also helps the system recess into the base.

Whether vent stacks or hidden vent lines are required for a design, the Multi-Flow LDVS proprietary connections allow for gases to collect and manifold into a perimeter line and breach the liner in only one location.

A functionally clean and efficient installation results, with few intrusions impacting the liner. That helps preserve the lining system’s integrity.

A GEOSYNTHETIC CONTAINMENT CHALLENGE

Drainage and venting geocomposites are often discussed in regards to roadway edge drains and sport field turf performance. Plenty of research has been dedicated to these areas, but drainage and venting is also deeply important to containment designs.

While the primary liner, such as a geomembrane, is the focus of much of the research in containment applications, professionals working in the field know the importance of the total system, and that includes the drainage and venting controls.

Poorly vented methane beneath a geosynthetic containment system can cause liner-destroying bubbles to form (“whales”). These whales can cause significant issues for wastewater lagoons, industrial processing facilities, animal waste lagoons, reservoirs, and other critical containment sites.

Whales have even been noted to lift concrete in canal systems.

For landfills and other waste disposal cells, improperly managed leachate and gases can lead to poor environmental performance and significant fines.

The overall cost of repair to any of these facilities to establish functional, dependable drainage and venting can be many times the upfront cost of proper design, specification, and CQA with solutions like the Multi-Flow LDVS.

MODULAR DRAINAGE AND VENTING SYSTEMS

Modular approaches to drainage and venting systems is one of the most significant ways to ensure more cost-effective containment installations. These systems are also a strong way to prepare and installation or planned installation for potential regulation changes. Systems that are modular have the ability to connect to future components, should regulations change.

In many applications, for example, this modular approach suggests the placement of collectors on 20 ft. intervals, draining them all to a monitoring sump with telemetrics to alert users of liquids under their liner for sampling. On the top end of the system, a vent fan easily provides constant draw on the lines and delivers collected gases either to atmosphere or maybe even storage. These systems can all tie together for effective and efficient monitoring.

Again, this is a scalable, adaptable solution, the efficiency of which makes it cost-effective yet unique for each site.

Multi-Flow LDVS doesn’t suggest large changes to the many (major) advances that have taken place in the lining industry; but drainage and venting innovations like this are essential to simplifying lining systems and making them more cost-effective. And that will continue to extend the acceptance and interest in geosynthetics for ponds, lagoons, landfills, industrial processing, and other containment-needing sites.

Drainage and venting materials and the resulting enhanced leak detection add practical and cost-effective mitigation systems with lasting benefits.

**

Andrew Plowman is Sales/Marketing Coordinator of Varicore Technologies, Inc. Multi-Flow LDVS is owned and operated by Varicore.