By Patricia Dolez, Eric Blond, and Pascal Saunier – Management of tailings, such as in oil sands operations, is one of the major operational and environmental challenges faced by the mining industry. The consolidation rate of the high water-content tailings is generally limited by their high physical stability and low hydraulic conductivity. Extended laboratory work conducted in the last three years has shown that the use of electrically conductive drain-tube planar geocomposites (eGCP) can accelerate the dewatering rate of oil sands tailings.

Oil sands tailings contain 70-80 wt% water; 20 – 30 wt% sand, silt, and clay; and 1 – 3 wt% residual bitumen. Sand settles rapidly and forms perimeter beaches while silt and clay fine particles are held in suspension by electrostatic interactions. Tailings reach about 30 wt% solids after a few years, at which point they are classified as mature fine tailings (MFT). With no significant further consolidation, they are transferred to containment basins.

These basins must be monitored for extended periods of time. The largest concerns they present to a facility owner are:

- Tailings ponds occupy a large surface area

- They have a very low bearing capacity

- They trap water, which becomes unavailable for further reuse by mine operations

- They pose a risk of accidental release of contaminants into surface water and groundwater

Mining companies have invested substantially in research on more effective oil sands tailings management strategies. They have tried consolidated and non-segregating tailings, as well as separate management of coarse and fine tailings using thin lift fines drying, thickening, centriguation, CO2 coagulation, water capping, freeze-thaw dewatering, filtering, and super-absorbent polymers.

An alternative technique based on electrokinetic dewatering with geosynthetic drainage support is providing some very promising results.

OIL SANDS TAILINGS & GEOCOMPOSITE DRAINAGE

An electrically conductive drain-tube planar geocomposite (eGCP) was developed to study the beneficial impact of geosynthetics drainage on oil sand tailings. The eGCP prototype combined a drain-tube planar geocomposite (made of a three-layer polyester nonwoven geotextile and, a drainage pipe) with a metal electrode. The geotextile had two outer filter layers and a heavier central drainage one. Its thickness was 3.7 mm (ASTM D5199), its mass per unit area was 420 g/m2 (ASTM D5261), and the filtration opening size (FOS) of its filter layers was 200 μm (ONGC 148.1-10).

The 20-mm outer diameter drainage pipe was made of perforated, corrugated polypropylene. It provided a high in-plane flow capacity.

The 20-mm outer diameter drainage pipe was made of perforated, corrugated polypropylene. It provided a high in-plane flow capacity.

The electrode consisted of a cylindrical tin-platted copper braid. It was positioned along the drainage pipe, which was inserted in a gusset within the geotextile.

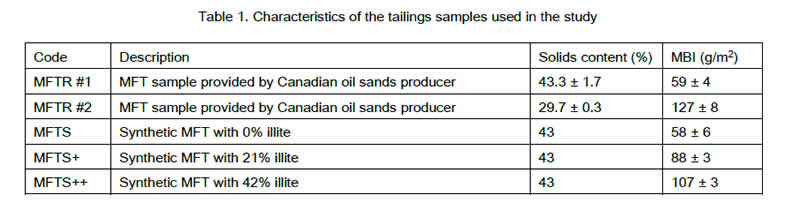

The research used two samples of mature fine tailings (MFT) from Canadian oil sands operations. Their solids content and Methylene Blue Index (MBI) value represented both ends of the range of typical MFT MBI values. Synthetic MFT was also used.

The behavior of the tailings was analyzed using a laboratory dewatering device developed to simulate the entire path of water taking place in real fluid fine tailings (FFT) disposal (i.e. self-weight consolidation, consolidation under the weight of the overlying fill, electro-osmosis, and drainage). The filtration and electro-osmosis dewatering behaviors of the tailings were also investigated individually using specially designed setups.

Using the laboratory dewatering device, a reduction of about 50% in the volume of MFT and an improvement in shear strength from nearly 0 kPa to a mean value of 25 kPa were obtained under the application of incremental normal stresses of 5, 10, and 20 kPa followed by the electrokinetic treatment. It took 25 to 140 days depending on the type of MFT. The energy consumed during the electrokinetic phase ranged between 75 and 218 Wh, i.e. 3.5 – 9.8 kWh per m3 of treated MFT.

The results show that different types of tailings may exhibit different responses to the application of the dewatering treatment, with respect to the duration and amount of water recovered at each phase of the process, and consumed energy. It also appeared that MBI, initial solids content, and general chemical composition alone cannot be used to predict the dewatering behavior of MFT by eGCP, their filtration by a geotextile, or the evolution of their shear strength as a function of the solids content.

As such, eGCP has a great potential for effectively accelerating the dewatering of oil sand tailings. The treatment parameters must be optimized, though, considering the tailings characteristics, in order to obtain optimal results.

Patricia I. Dolez is with the University of Alberta. Eric Blond is a geosynthetics engineering consultant. Pascal Saunier works for Afitex-Texel Geosynthetics inc. The full version of this research was published in the GeoAmericas 2016 Proceedings.