By Angel Diaz and Chris Timpson – Geotextile tubes help to prevent storm damage and protect the environment through the building of custom marine structures. The installation of geotextile containers can be temporary or permanent, and in most cases the structures are invisible to the coastal environment. The technology involves the fabrication of a large containers made of a specially engineered textiles, which are filled with dredged sediments or sand on-site.

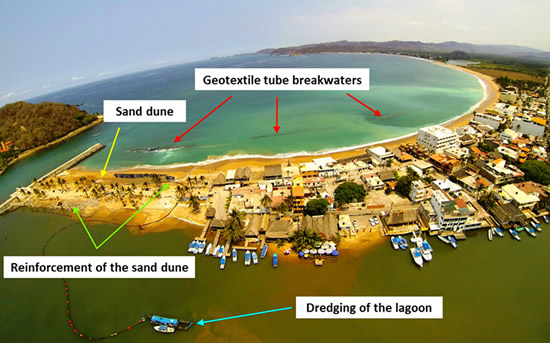

A project in Barra de Navidad, Jalisco, Mexico, offers an exemplary case of the benefits and use of geotextile tubes for breakwater designs and beach restoration.

BEACH EROSION AND A HURRICANE

The town of Barra de Navidad, population 5000, is located on Mexico’s Pacific Coast in the Costa Alegre zone of the state of Jalisco. The town itself dates to 1540, when it became a Spanish colony. The first roundtrip expeditions to the Philippines originated here.

Today, the major economic activity for Barra de Navidad is generated by tourism, aquaculture, and fishing. Much of the commercial success is focused in a 2 km stretch of gold sand beach, and, in particular, in an 800m beach zone where the primary hotels, restaurants, and affiliated businesses are located.

Normal tidal activity and increasing sea storm intensity have led to erosion of the beach that separated the ocean from the lagoon area in which commercial activity was centered. It concerned the area, but 2011’s Hurricane Jova—a Category 2 storm—proved to be the tipping point. Its landfall caused major destruction of infrastructures in the region. Slopes, highways, access roads, streets, buildings and homes, floods, power outages, and civilian deaths occurred.

Barra de Navidad needed to re-engineer its shoreline.

GEOTEXTILE TUBES FOR BEACH RESTORATION

Engineers designed a project that takes advantage of the hundreds of thousands m3 of sediments at the lagoon for filling geotextile tubes to build protection structures at the beach front. Wave propagation models and bathymetric studies were conducted to evaluate the proper placement of artificial marine structures. Three artificial reefs were approved, in a section of 600m starting from the side groin. The breakwaters were designed to be 100m long and spaced 50m apart.

MORE GEO: “Healing the World: A Geosynthetics Solution”

The 2-1 pyramidal configuration (2 geotextile tubes at the base, 1 geotextile tube on top) was constructed to a maximum structure height of 4m. All were calculated to be submerged at least 40cm, considering the mean lower low water (MLLW). Between each breakwater, a 50m single-level geotextile tube was submerged with a maximum height of 2m. These sand-colored geosynthetic structures were installed to promote sand accumulation and to prevent the Venturi Effect (sweeping along sand from the dune).

The lagoon was dredged to return it to a healthy state, and reclaimed fill taken from the lagoon was pumped into the geotextile tubes. The pumping distance was kept in a range of 250 – 300m.

DESIGNING WITH GEOTEXTILE TUBES

The tube fabric was selected based on the need to have high mechanical strength, excellent filtration properties, and resistance to natural chemicals (acid or alkaline), saltwater, and UV degradation. The geotextiles also needed to be inert in the environment. Woven polypropylene geosynthetic fabrics in black and tan marine beach colors (depending on if the tube was potentially viewable) were chosen. The wide width tensile strength (at ultimate) was 200kN/m in both cross and machine direction. The factory seam strength was 160kN/m, according to the ASTM D4595 and D4884 test methods.

Filtration concerns took into consideration the apparent opening size (AOS) value of 0.6mm according to the ASTM D4751 test method respectively. Geotextile selection and software simulation testing were conducted together, in order to achieve an optimum technical, workable, visually acceptable, and cost-effective design.

Each Geotube® container had to be more than 20m in length and three mechanical filling ports were included to assist in evenly distributing sand along the tube length. The dimensions of the geotextile tubes installed at the terminal were 10.3m circumference, 27m and 23m long, and a maximum pumping height of 2m. The different lengths helped ensure that the ends of the geotextile tubes did not meet at any point within the 2-1 pyramidal configuration. This piece of the design was custom-made for the Barra de Navidad project.

Each of these tubes enabled an ~6.9m3 volume/meter up to the 2m pumping height designed. The weight of each element was estimated between 159 and 187 tons.

The 100m breakwaters were formed by 12 geotextile tube units and the 50m single submerged structure was formed by two geotextile tube units. A total of 42 geotextile tube units were installed in less than two months.

RESULTS

More than 300 families were benefited directly with the project for their front beach buildings and businesses such as hotels, restaurants, bars and shops. The economic activity recovered as the beach was again appropriate for being visited by tourists. The artificial breakwaters filled with the sediments from the lagoon resisted the season of storms in 2014 protecting the restored beach as expected, and shortly started to be covered with marine life attracting scientists form the State of Jalisco for investigation. New opportunities for scuba diving close to the artificial breakwaters are being explored by the inhabitants as a commercial attraction increasing the offer of activities at the town.

Geotextile tube technology proved to be a solution that could be used to create marine structures for shoreline protection and at the same time could take advantage of being used for the confinement of dredge material.

Learn more about geotextile tubes and other TenCate engineering and geosynthetics at www.tencategeo.us.

Angel H Diaz Jr. works for Geomembranas y Geosintéticos SA de CV. Chris Timpson previously worked for TenCate Geosynthetics Americas. He is currently with Watershed Geo. A longer version of this was published in the GeoAmericas 2016 proceedings, published by Geosynthetica.

Good article, we have a similar project in Lagos Nigeria and have requirement for geotextile geotubes for sand break water project and restoration.