Last year, Titan Environmental released two fiberglass geogrid products, TE-FGP and TE-FGC, which is a geogrid-geotextile composite. The products were engineered with a polymer coating to endure higher temperatures (up to 900° F) and with very low shrinkage potential, thus keeping asphaltic systems rigid. Now, the company has released the next phase in its geogrid development: a polymer-coated fiberglass geogrid with a polymeric tack film layer in lieu of a conventional tack coat.

”The softening point of the tack film is tested at low temperature of 78° C ( 172° F), which would ensure that the tack-film melts during the paving operation,” says Sam Bhat, VP of Global Business Development for Titan. “[This facilitates] a stronger bond with the asphalt layer. Our past installation experiences have shown that strong and solid bonding of a fiberglass geogrid is essential to achieving successful structural asphalt reinforcement. ”

TACK FILM ON GEOGRID

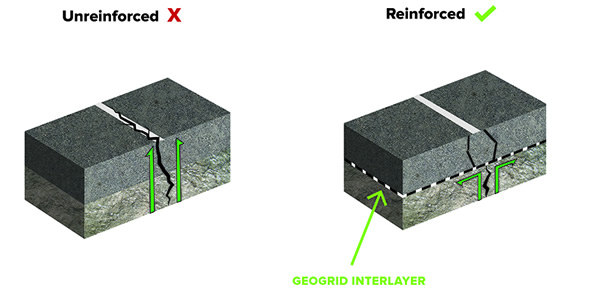

The TE-FG-TF fiberglass geogrid product features a pressure-sensitive, self-adhesive backing on one side and a polymeric tack film on the other. The tack film provides stronger adhesion to asphalt layers and optimizes the chemical compatibility between the fiberglass geogrid reinforcement and the pavement overlay, thus creating a stronger bond.

The development is particularly suited to new pavement installations or rehabilitation of newer surfaces, the company notes. (Very old pavements may still require a very light tack coat.)

The product has been developed for use with all types of asphalt mixes and for use in highways, airport runways and taxiways, bridges, parking lots, jointed concrete highways to control reflective cracking, and other roadway applications. No curing time is needed for the tack film.

Additional benefits of the new tack film layer product include:

- Reduces effects of thermal, reflective, block, and alligator cracking

- Reduction of rutting of pavements subjected to high ambient temperatures and intense wheel loadings

- Provides cost benefit by extending pavement structural life for airport runways, highways, high volume roads, parking lots, and more

- Increases the fatigue life of pavements with weak foundations

- Reduces the overlay thickness of pavement systems

- Fast, easy installation; material is recyclable; and the fiberglass geogrid with tack film is suitable for all types of asphalt mixes

Learn more about the fiberglass geogrids, tack film options, and other geosynthetics at www.titanenviro.ca. For direct engineering and material information, contact Sam Bhat at sam@titanenviro.ca.