The M1 Highway is a major European route, connecting Moscow and Warsaw. Along the way, the trunk road passes through Smolensk and crosses into Belarus to connect the major cities of Minsk and Brest to the roadway system. When a section along the Brest – Moscow portion suffered fatigue cracking, a geosynthetic asphalt reinforcement solution was specified.

M1 ASPHALT REINFORCEMENT

The problematic cracking was discovered along section 607 – 609 km of the M1. The surface fatigue cracks were significant enough that they were still able to be observed after conventional milling of the road surface.

Engineers called for the cracks to be sealed and asphalt reinforcement to be added to ensure long-term stability of the highway section. A glass fiber geogrids, Asphaltex GLASS (50/50)-40 from Machina-TST, was selected.

The geosynthetic solution here is a warp-knitted geogrid enhanced by glass rovings and bitumen impregnation. The geogrid structure is subsequently resistant to the high temperatures in asphalt laying works. The glass fiber grid is also highly resistant to chemical and biological factors in soils and roadway environments.

The asphalt reinforcement geogrid provides high tensile strength for the roadway. The bitumen impregnated structure also ensures a strong adhesion to asphalt layers, further strengthening the overall roadway structure.

SEE ALSO: Runway Reinforcement for National Airport in Minsk, Belarus

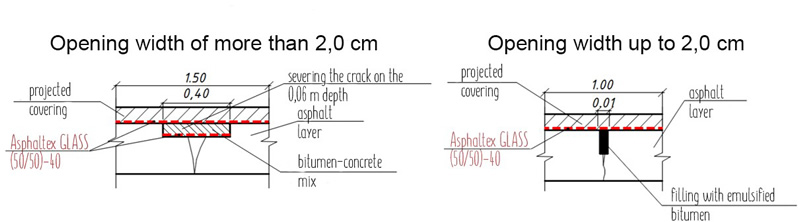

During the road rehabilitation works, surface cracks were filled with a bitumen emulsion, after which 1m-wide geogrid strips were installed along the crack zones.

Transportation engineers recommended that the asphalt reinforcement plan be carried out in this fashion, with separate strips of the geomaterial installed only on the locations of cracks and directly above them when there were expansion cracks on the existing coating. The distance between these strips was not to be less than 8 m.

The width of the geosynthetic asphalt interlayer was calculated in accordance with the width of the crack opening. (The geosynthetic width here needed to be at least 1m.)

Installation of the asphalt reinforcement layer was carried out only after cracks were filled and the binder had been spread.

**

Learn more about Machina-TST’s reinforcement expertise, geosynthetic manufacturing, and global markets at www.mahina-tst.com.