The United States Army Corps of Engineers controls more than 14,000 miles of levees. An additional 85,000+ miles of levees are privately owned and operated. To help improve strategies for preventing or responding to levee breach scenarios, USACE has constructed a Full-Scale Levee Breach and Hydraulic Test Facility in Vicksburg, Mississippi. A reinforced composite geomembrane lining system from OwensCorning plays a central role in the facility’s success.

Vicksburg has played an important role in advancing infrastructure with geosynthetics. In the 1970s, work at the Vicksburg-based Waterways Experiment Station with Presto Geosystems led to the mass market introduction of geocell systems.

For the Full-Scale Levee Breach and Hydraulic Test Facility, USACE installed pre-fabricated panels of RhinoMat 1000 Reinforced Composite Geomembrane.

LEVEE BREACH TESTING

According to USACE, the 11-acre, 4-million gallon test facility is the only one of its kind in the world that “allows researchers to validate results of small-, mid-, and full-scale levee breach experiments.”

The facility also serves as a training ground for Rapid Response to Levee Breach (RRLB) emplacement teams.

The site was completed in 2010 and has been utilized extensively. A 2017 relining initiative added the reinforced geomembrane.

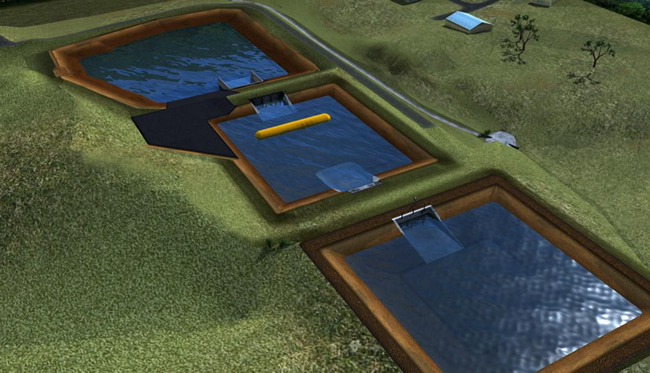

“It’s a hydraulic system of three ponds in succession,” says Andy Durham of OwensCorning, who has documented much of the lining work. “[There’s] an upper source basin, a middle test basin, a lower catch basin. The catch basin typically stays full. They can pump water up to the source basin at the top, let that water come through a spillway into a test basin, where they can construct model levees, breach those levees, and then do training exercises to rapidly repair those levees as water comes through.”

Durham provides a number of key details about the facility in the video. He also takes time to cite the work of key project partners, including the earthworks contractor (Vinco Inc.), the geomembrane fabricator (EPI), and the installer (ECS of Florida).

OwensCorning provided RhinoMat 1000 geomembrane for the key source basin lining system. The 94 x 94-ft. basin has a 2.2-million-gallon capacity. The 1:3 sloped embankments of the cell and the depth of 17 ft. supports a flow rate of 2,000 CFS into the test basin.

Learn more about RhinoMat geomembranes

See the USACE page for the levee breach test facility