The City of Calgary wanted to reduce construction and maintenance costs of concrete pedestrian sidewalks. The traditional approach used by the city was to use thick, unreinforced concrete slabs. Yearly rehabilitation work was required to repair major cracking of the slabs shortly after installation. Project planners looked for a reinforcement system that would not be susceptible to corrosion and that would minimize and delay concrete surface crack formation.

A high-strength polymer geogrid product, TITAN ConForce Grid, was specified. This unique product had been engineered to reinforce concrete pathways.

The city expects to save 12% in material costs where the concrete reinforcement geogrid is installed. Additionally, the city will realize greater long-term savings by increasing the life cycle of its sidewalks and reducing maintenance costs associated with frequent premature repairs.

In Calgary, the geogrid solution offered numerous benefits. It was lighter than conventional steel rebar while delivering higher tensile, flexural, and shear strength. This enabled the solution to offer better reinforcement and control of surface shrinkage cracking than conventional rebar.

CONCRETE REINFORCEMENT WITH POLYMERIC GRID IN CALGARY

The project utilized three different placements of the concrete reinforcement geogrid and found all slabs performed exceptionally well over a one-year test period.

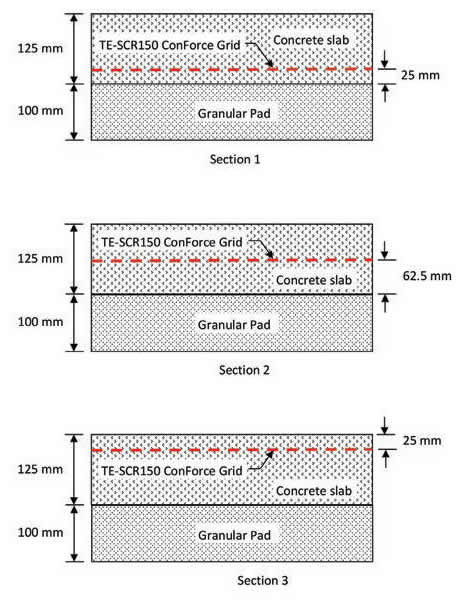

Three 125-mm-thick concrete slabs created three sections of sidewalk to be reinforced with the concrete reinforcement geogrid. The slabs were place on a 100-mm-thick compacted granular base. The slabs consisted of road standard concrete #32mpa with an 80/plus 20 slump mix. The ConForce Grid was placed at different levels in each of the slabs with the objective of studying its performance in each sidewalk section.

In the first section the grid was placed towards the top of the concrete slab. In the second section, the grid was placed in the middle of the concrete slab. In the third, the grid was placed towards the bottom of the slab.

After a year, the project team returned to assess performance. No surface cracking was observed.

HOW CONFORCE GRID WORKS

How does the solution work? TITAN ConForce Grid is a high-strength polymer geogrid designed as an alternative to conventional steel for reinforcement of concrete. This stiff geogrid is non-corrodible and can provide durable reinforcement in aggressive and non-aggressive environments. It functions to distribute and resist tensile stresses in the concrete structure that might cause unacceptable cracking and/or structural failure; increases the flexural stiffness and shear strength of the concrete; and significantly improves post-crack ductility of the concrete structure.

It can be used as a technically superior alternative to conventional steel reinforcement in a wide range of applications, such as:

- Concrete pavement

- Pathways

- Ground-supported concrete slabs

- Floating slabs

- Bridge beams

- Exposed concrete surfaces

- Concrete piles

- Columns

- Retaining walls

The primary benefits:

- Superior structural integrity — Testing revealed the product to be far less affected by corrosion, allowing for higher structural and reinforcement integrity than steel

- Superior reinforcement and control of surface shrinkage cracking — TITAN ConForce Grid’s higher tensile, flexural and shear strength properties make the concrete slabs stronger and less susceptible to cracking

- Cost Savings — The City of Calgary expects to save 12% in material costs with this solution, in addition to realizing greater long-term savings by increasing the life cycle of its sidewalks and reducing maintenance costs associated with frequent premature repairs

Learn more about Titan’s geogrids and global network at https://www.titanenviro.com. For inquiries please contact Titan’s Chief Technical Officer, Sam Bhat at: info@titanenviro.com or 1-204-878-3955 | 1-866-327-1957.