In the latest addition to our continuing series of articles developed out of the GAP 2019 transportation engineering conference proceedings, we follow Eli Cuelho, a senior engineer with TRI Environmental. Cuelho has contributed significantly to the transportation field, through his roadway and railway-related research for DOTs and with his accelerated pavement testing and cyclic plate load testing laboratory. Here, his work focused on a key question to highway base courses today. Crushed and processed aggregate are typically a cost effective means of carrying loads and reducing the thickness of the asphalt layer in paved roads—but, for some projects (such as in Montana), obtaining materials that meet the current specifications for crushed base course is becoming uneconomical due to declining resources. Could a more attainable ¾-inch minus gradation serve infrastructure?

1. INTRODUCTION TO ¾-INCH MINUS CRUSHED BASE

This project was initiated to determine the viability of a ¾-inch minus gradation specification for crushed base course materials for the state of Montana to allow gradations with smaller nominal aggregate sizes to be produced for road construction purposes, the results of which are fully documented in a final report to the Montana Department of Transportation by Cuelho (2016). The first step in this investigation was to review U.S. state and federal standard specifications to document existing ¾-inch minus base course specifications. Standard specifications from all 50 states were reviewed to extract gradation specifications for ¾-inch minus base course aggregates used as the compacted structural layer in highway construction. Information from that review helped identify a starting point from which to develop a standard specification for Montana crushed aggregate courses.

Samples of aggregate were collected from eight different gravel pits geographically located throughout Montana. When necessary, portions of these gravel samples were crushed to create ¾-inch minus mixes, and then these gradations were further modified to evaluate the effect that gradation had on their engineering properties.

RELATED: The Benefits of Accelerated Pavement Testing on Infrastructure

The primary objective of this project was met by analyzing two specific aspects of the ¾-inch minus gradations: 1) whether aggregates whose maximum particle size was ¾ inch would perform at least as good as Montana’s current 5A (2-inch minus) and/or 6A (1½-inch minus) crushed aggregate base course materials, and 2) what the effect changes in the gradation had on the material properties within the specified limits. The first goal was accomplished by comparing data from the ¾-inch minus materials tested during this project to data from an earlier study conducted on Montana CBC-6A and CBC-5A materials by Mokwa et al. (2007). The second goal was accomplished by qualitatively analyzing the performance data from finer and coarser gradations for each of the eight Montana sources. The results from this analysis were used to suggest a viable ¾-inch minus gradation specification for crushed base course materials for the state of Montana. Other states experiencing shortages in aggregate base course materials having larger sized particles may wish to adopt the results of this study or implement similar studies to evaluate the feasibility of modifying their crushed base course gradation specifications.

2. REVIEW AND COMPARISON OF STATE AND FEDERAL ¾-INCH MINUS BASE COURSE SPECIFICATIONS

Current Montana specifications exist for a 2-inch minus (Grade 5A) and 1½-inch minus (Grade 6A) crushed aggregate course (MDT, 2014 – §701.02.4); however, because gravel sources in Montana are becoming limited, investigating the use of a gravel specification for maximum particle sizes less than ¾ inch is desirable. The first step in this investigation was to review other state’s standard specifications to document whether or not a standard ¾-inch minus base course specification is currently being utilized. Information from these specifications helped identify a starting point from which to develop a standard specification for Montana crushed aggregate courses having smaller maximum aggregate size.

Standard specifications from all 50 states were reviewed to extract gradation specifications for ¾-inch minus base course aggregates used as the compacted structural layer in highway construction. Only a few states had standard specifications for ¾-inch minus base course materials. Based on a qualitative analysis of the specifications and further discussions with personnel from departments of transportation having the most promising specifications, a ¾-inch minus specification from Colorado DOT was selected as the interim ¾-inch minus specification to produce material mixes for this project. The Colorado specification was used extensively for base course aggregate, and was originally thought to be developed using specifications from the Federal Highway Administration (FHWA), which were also reviewed as part of this effort.

3. CHARACTERIZATION OF ¾-INCH MINUS BASE COURSE MATERIALS FROM MONTANA

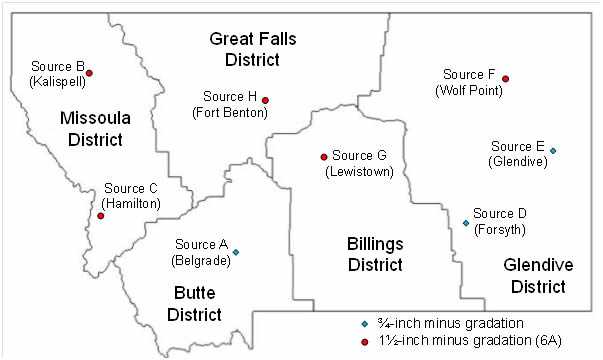

Samples of aggregate were collected from eight different gravel pits geographically located throughout Montana (Figure 1). Samples were obtained from all five transportation districts in Montana, and are generally representative of aggregates used for road construction purposes within those districts. Five of the eight sources were Montana Type 6A CBC 1½-inch minus aggregates (Sources B, C, F, G and H); and three sources were ¾-inch minus materials (Sources A, D and E). For the 1½-inch minus materials, stones larger than ¾ inch were crushed using a miniature jaw crusher until all of the material passed the ¾-inch sieve. The crushed material was simply added back to the entire mix creating a simulated ¾-inch minus mix, hereafter referred to as the “Prepared” mix. Using the Prepared gradation as a base, a second mix was created by making it coarser or finer to determine the effect that changes in the gradation had on its engineering properties. This mixture is hereafter referred to as the “Modified” mix.

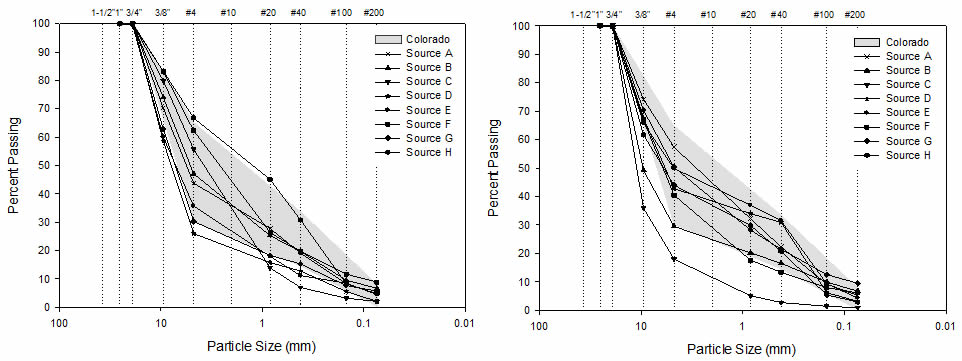

Particle size distributions were compared to the upper and lower gradation limits associated with Colorado’s ¾-inch minus specification, which was identified by the Technical Panel as the target gradation for this effort. Gradation results from the Prepared and Modified mixes are plotted with respect to the Colorado ¾-inch minus specification upper and lower limits, as shown in Figure 2.

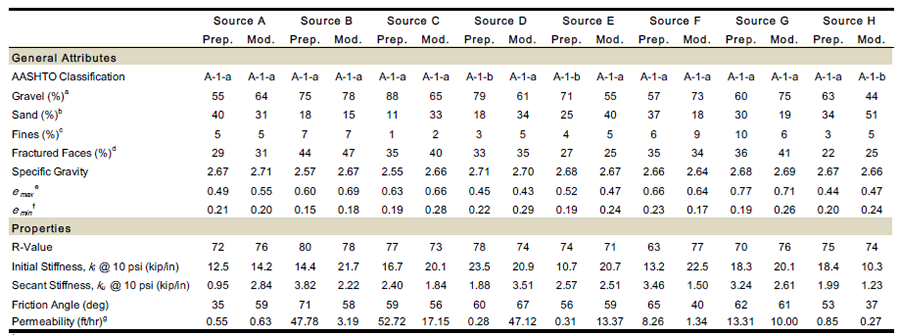

General properties of the aggregate mixes were determined using several laboratory tests, including: particle size distribution (ASTM D6913, ASTM D1140, and MT-202), fractured face count (ASTM D5821 and MT-217), Modified Proctor density (ASTM D1557 and MT-230), relative density (ASTM D4253 and ASTM D4254), and specific gravity (ASTM D854, ASTM C127, MT-205, and MT-220). Performance properties were evaluated using R-value (ASTM D2844), direct shear (AASHTO T236), and permeability (ASTM D2434 and AASHTO T215) tests. Friction angle, initial stiffness, and ultimate secant stiffness were determined from direct shear tests. A summary of the properties for all of the gravel mixes is presented in Table 1.

aPercent retained above the #10 sieve

b Percent retained between the #10 and #200 sieves

c Percent passing the #200 sieve

d For particles retained above the #4 sieve

e Based on dry relative density tests

f Based on wet relative density tests

g Average of all permeability tests performed

4. DATA ANALYSIS AND RESULTS

The primary objective of this project was accomplished by analyzing the results of the characterization and performance test results for all the mixes. The first part of the analysis was to determine whether aggregates whose maximum particle size was ¾ inch would perform at least as good as Montana’s current 5A and/or 6A crushed aggregate base course materials. This was accomplished through multiple laboratory tests to characterize the material properties of the ¾-inch minus mixes from around Montana, and comparing that data to the results from laboratory tests conducted on CBC-6A and CBC- 5A materials (Mokwa et al., 2007). The second part of the analysis was to determine the effect changes in the gradation had within the specified limits. This was accomplished by qualitatively analyzing the performance data from finer and coarser gradations for each of the eight Montana sources. The results from this analysis were used to suggest a viable ¾-inch minus gradation specification for crushed base course materials for the state of Montana.

4.1 Statistical Analysis

The results of strength, stiffness and permeability tests conducted on the eight ¾-inch minus mixes from Montana were compared to the results from laboratory tests previously conducted on Montana CBC-6A and CBC-5A materials by Mokwa et al. (2007). Statistical analyses of average values based were conducted using a two-sided t-test (for samples having unequal variance) to determine if apparent trends in measured laboratory test results represent true differences between aggregate types. The two-sample t-test is a statistical test used to determine if the averages of the two data sets are statistically different from one another based on a mathematical evaluation of the data scatter. In cases where the averages are statistically different, a direct comparison of the mean values indicates which value is greater. Otherwise, the means are considered statistically equal.

The output from this analysis is a parameter called a p-value. In this study, the p-value ranges from 0.500 to 1.000 (based on the one-tailed distribution). Although not typically shown this way, the pvalues can be used to determine how two averages compare to one another. P-values closer to 0.500 indicate that the means are statistically more similar to one another and p-values closer to 1.000 indicate the means are statistically more different from one another. For the purposes of comparison, and taking into account the relatively variability typical observed in geotechnical test data, a p-value greater than 0.850 was selected to indicate that the two means were statistically different from one another, while p-values between 0.500 and 0.850 indicated that the means were statistically the same.

There are great number of comparisons that are possible to compare the performance of the ¾-inch minus materials to the Montana 6A and 5A materials characterized in Mokwa et al. (2007); therefore, the number of these comparisons was limited to those most important to base course applications – strength, stiffness, and drainage. Material properties determined during this study related to these characteristics are R-value, friction angle, secant stiffness, initial stiffness and permeability.

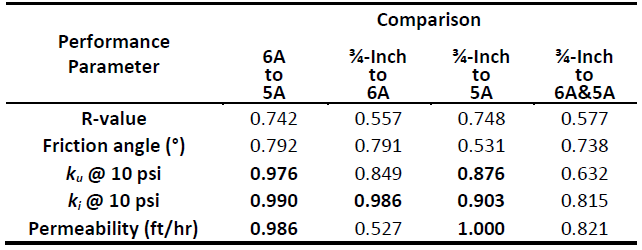

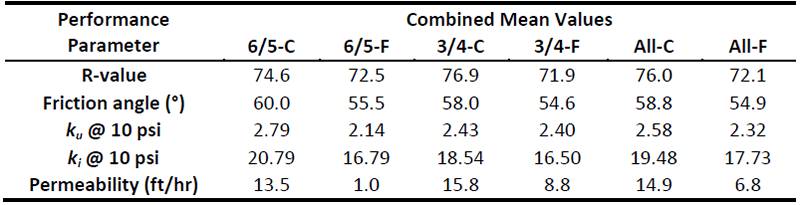

Comparisons were accomplished by grouping the data into meaningful data sets. The first comparisons were centered on data sets grouped by material type. Four different groupings of materials were used to make these comparisons: 6A materials from Mokwa et al. (2007), 5A materials from Mokwa et al. (2007), a combined group of ¾-inch minus Prepared and Modified mixes, and a combined group of 6A and 5A mixes. The combined mean values associated with each of these data sets are listed in Table 2.

The results of the various comparisons between these data sets are listed in Table 3. In general, it was observed that the ¾-inch minus materials were relatively similar in performance to the 6A materials, with the exception that the initial stiffness was slightly greater in the 6A materials. There were no statistically significant differences in the R-value or friction angle between any of the materials. The ¾- inch minus materials performed better than the 5A materials (similar to the 6A materials). Bold numbers signify values greater than 0.850 indicating a statistically relevant difference between the two means.

An attempt was also made to determine the effect that modifying the gradation within the acceptable limits of the ¾-inch minus specified range had on its material properties. In this case, materials that were finer were compared to materials that were coarser. The percent of gravel was used as a means of separating the data sets into groups. A threshold of 70 percent gravel (defined as materials retained above the #10 sieve) was used to delineate between coarser and finer materials, with materials having greater than 70 percent gravel being assigned to the coarser group and materials having less than 70 percent gravel being assigned to the finer group. Each of the broader groups of data (Montana 6A and 5A materials from Mokwa et al. (2007) and the ¾-inch minus materials) were split into these two broad groupings based on this criteria.

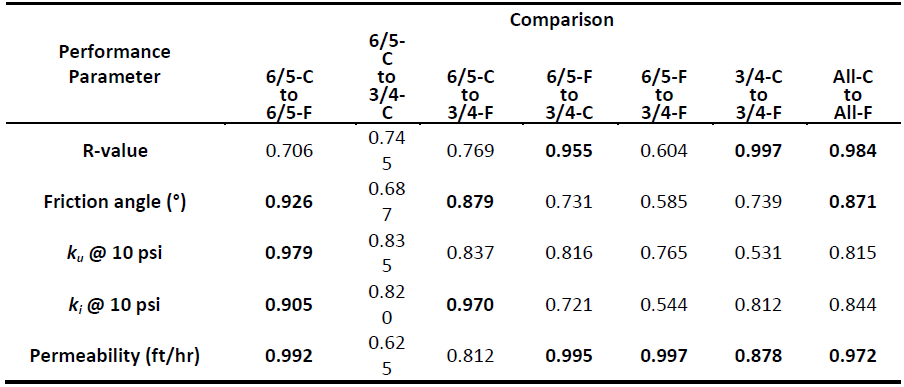

MORE GAP: Assessment of Historical Army Airfield Pavement Condition Data

The few number of data points prevented further parsing of the data beyond the following four categories: 6A & 5A – coarser (6/5-C), 6A & 5A – finer (6/5-F), ¾-in minus – coarser (3/4-C), and ¾-inch minus – finer (3/4-F). For the purposes of this comparison, 6A and 5A were also combined into a single data set, mainly because there was not enough data to facilitate meaningful statistical comparisons if parsed too small. Two additional data sets were created by combining all of the coarser materials and finer materials, All-C and All-F, respectively. Combined mean values for each category are listed in Table 4. The two-sample t-test described above was used to compare the means from these data sets. The results of the statistical comparisons are summarized in Table 5. Again, bold numbers signify values greater than 0.850 indicating a statistically relevant difference between the two means.

Several statistically relevant differences are apparent. Perhaps most notably, the comparison between the coarser and finer 6A & 5A materials showed that mean friction angle, secant stiffness and initial stiffness, and permeability were all statistically greater in the coarser 6A & 5A materials (referring to far left column in Table 5). Likewise, the R-value, friction angle, and permeability were greater in the coarser materials in general (referring to far right column in Table 5). Other relevant comparisons showed that R-value and permeability were greater in the coarse ¾-inch minus material when compared to the finer 6A & 5A material. Also, the permeability in the finer ¾-inch minus material is greater than the finer 6A & 5A material. Lastly, the performance of the coarser ¾-inch minus material is generally similar to the coarser 6A & 5A material (refer to column second from the left in Table 5).

4.2 Qualitative Analysis

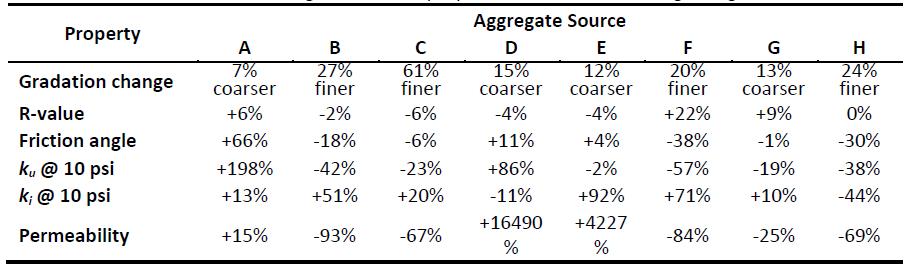

As described earlier above, two gravel mixes were prepared for each of the eight Montana gravel sources by crushing materials greater than ¾-in. and adding them back into the mixture (Prepared mix), then modifying the gradation by removing and/or adding certain sized particles (Modified mix). These manipulations either made the gradations finer or coarser depending on the quantity and size of materials added or removed. While the degree of coarseness or fineness is somewhat arbitrary, for the purposes of this analysis, the area under the gradation curve was used as the means to quantitatively determine how much finer or coarser the Modified mixes were in comparison to the Prepared mix. Gradations with greater area were finer and those with lower areas were coarser. The amount of change in either direction was the most important outcome, and was expressed as a percent change. Differences in the material properties of finer or coarser mixes from each source were compared using the laboratory test data summarized in Table 1. Changes in the individual properties between the Prepared mixes to the Modified mixes were also expressed in terms of percent change. The results of this analysis are summarized in Table 6.

Referring to Table 6, each source was qualitatively evaluated to determine overall the effect was from adjusting the gradation finer or coarser for each source. Overall, making the mixes finer generally caused a decrease in the friction angle, secant strength and permeability. Materials that had a significant increase in fines showed the greatest decrease in permeability. These results indicate that the upper bound of the gradation is most critical. It is therefore recommended that the upper bound of finer materials be decreased to ensure that the permeability of these materials is not negatively affected. The effective diameter (i.e., the diameter of the particle size associated with 10 percent passing, or D10) has been shown to influences the permeability of sands and gravels (Chapuis, 2004); however, the D10 of the Source D and Source E materials showed only a modest change between the Prepared and Modified mixes. It was also noticed that the amount passing the #40 sieve in these two mixes greatly decreased, which may have also contributed to the improvement in permeability.

Specifically, gradations with greater amounts passing the #40 sieve had significantly lower permeability (i.e., Source A-Prep, Source A-Mod, Source D-Prep, Source E-Prep, and Source H-Mod).

5. MONTANA ¾-INCH MINUS SPECIFICATION

The purpose of this project was to determine whether crushed base course materials that had a maximum particle size of ¾-in. would perform at least as well as current Montana CBC-6A and CBC-5A base course materials and, if so, establish the boundaries of a gradation specification for these materials. The analysis conducted during this project showed that, overall, ¾-inch minus base course materials work at least as well as Montana CBC-6A and better than Montana CBC-5A materials. It also showed that ¾-inch minus materials within the preliminary specified range performed better near the bottom of the range (i.e., coarser materials) than finer materials. For the most part, the performance characteristics were acceptable for the ¾-inch minus materials tested; however, Sources A and H had lower friction angles, stiffnesses, and poor permeability. Sources D-Prep and E-Prep had poor drainage, and Source F-Mod had lower strengths and relatively low permeability. The final gradation bounds of this suggested gradation are shown in Figure 3, as compared to the Montana 6A and 5A materials. The practicality of producing these mixes and their constructability is under qualitative review by the state.

6. RECOMMENDATIONS

Gravel bases are a critical component of roads, providing drainage, structural support, and load distribution. Montana specifications currently allow 2-inch minus (Grade 5A) and 1½-inch minus (Grade 6A) crushed base course materials (Section 701.02.4); however, gravel sources in Montana are becoming limited, particularly in the eastern regions of the state, making the option to use a ¾-inch gravel base desirable. The objective of the proposed project was to develop a standard specification for a new gravel base course with nominal maximum aggregate size of ¾ in. The first step in this investigation was to review other state and federal standard specifications to document existing ¾-inch minus base course specifications. Information from that review helped identify a starting point from which to develop a standard specification for Montana crushed aggregate courses. A ¾-inch minus specification from the state of Colorado was used as a preliminary specification in order to produce ¾- inch minus mixes with Montana aggregates for testing purposes.

The most important engineering characteristics of any base course aggregate are strength, stiffness, and drainage capacity. Therefore, the second step in this investigation was to test a variety of crushed aggregates from several ¾-inch minus gradations from various sources throughout Montana to determine their general properties and performance characteristics. Material properties were quantified by synthesizing and analyzing results from the following laboratory tests: geotechnical index tests (particle size distribution, fractured face count, modified Proctor density, relative density, and specific gravity), direct shear, R-value, and permeability.

Data from these tests were compared to existing performance data from crushed base course mixes CBC-6A and CBC-5A previously documented by Mokwa et al. (2007). A two-sided t-test was used to determine whether the averages of the two data sets were statistically different from one another based on a mathematical evaluation of the data scatter. When the performance characteristics of the ¾-inch minus materials were compared to those of the 6A and 5A materials, the following conclusions were made:

- The ¾-inch minus materials perform similarly to the CBC-6A materials, with the exception that the initial stiffness is slightly greater in the 6A materials.

- Similar to the 6A materials, the ¾-inch minus materials performed better than the 5A materials.

- There were no statistically significant differences in the R-value or friction angle between any of the materials.

A second analysis was conducted to evaluate the effect that modifying the gradation had on the performance of the ¾-inch minus gravel. A threshold of 70 percent gravel was used to delineate between coarser and finer materials, with materials having greater than 70 percent gravel being coarser and with materials having less than 70 percent gravel being finer. The following general conclusions were made based on statistical comparisons of these data sets:

- The mean friction angle, secant stiffness and initial stiffness, and permeability were all statistically greater in the coarser 6A & 5A materials when compared to the finer 6A & 5A materials.

- The R-value, friction angle, and permeability were greater in the coarser materials in general when compared to the finer materials.

- The R-value and permeability were greater in the coarser ¾-inch minus materials when compared to the finer 6A & 5A materials.

- The permeability in the finer ¾-inch minus materials are greater than the finer 6A & 5A materials.

- The performance of the coarser ¾-inch minus materials are generally similar to the coarser 6A & 5A materials.

A qualitative analysis was also performed to determine the effect that modifying the mixes by making them either finer or coarser had on their material properties. The following conclusions were drawn from this analysis:

- Overall, making the mixes finer caused a decrease in the friction angle, secant strength and permeability.

- Materials that had a significant increase in fines showed the greatest decrease in permeability.

- Specifically, gradations with greater amounts passing the #40 sieve had significantly lower permeability (i.e., Source A-Prep, Source A-Mod, Source D-Prep, Source E-Prep, and Source H-Mod).

Based on the results of this project, a new specification for a ¾-inch base course specification within the state of Montana (Montana CBC-7A) was suggested. The practicality of producing these mixes and their constructability is under qualitative review by the state.

Eli Cuelho, P.E., is a senior engineer with TRI Environmental, Inc.

REFERENCES

Chapuis, R. (2004) “Predicting the Saturated Hydraulic Conductivity of Sand and Gravel using Effective Diameter and Void Ratio,” Canadian Geotechnical Journal, 41 (5): 787-795.

Cuelho, E. (2016) “Development of a ¾-Inch Minus Base Course Type A Specification for Montana,” Final Report to the Montana Department of Transportation, FHWA/MT16-015-8228-001.

Mokwa, R., Trimble, N. and Cuelho, E. (2007) “Experimental Assessment of Aggregate Surfacing Materials,” Final report to the Montana Department of Transportation, FHWA/MT-07-011/8117-30.