|

In order to stay competitive and safe, airports today face a number engineering design challenges. Capacities must be expanded and efficiencies increased without adversely impacting safety.

Increasing environmental protections require stringent control of stormwater runoff, strict containment of fuel resources, and, where applicable, deicing facility containment and drainage. Also, as technology in airplane manufacture and design has advanced, larger and stronger runways must be constructed to accommodate the vast range of plane styles and weights.

Geosynthetics are playing a strong role in meeting these engineering design challenges, as well as offering greener design solutions and reduced long-term maintenance needs.

Runway Requirements

|

The epicenter of safety concerns for any airport is managing traffic along the highly complex network of runways, taxi lanes, airport service roads, and tunnels that enable planes, baggage carts, emergency and maintenance vehicles, fuel trucks and more to go about their necessary business. While the primary incursion and excursion safety concerns are taken care of by tower and ground personnel, environmental protections and runway integrity concerns are taken care of through smart construction and engineering practices.

Runway surfaces must be kept free from contamination, to maintain the optimal surface friction characteristics that influence an airplane’s drag and take-off and landing safety. Ensuring these surface characteristics requires strong drainage management of stormwater, fuel and deicing agents. Runways must also accommodate frequent, intense cycles of compression and decompression with airplane take-offs and landings.

The International Civil Aviation Organization’s (ICAO) 9157 “Aerodrome Design Manual” provides guidance on the geometric design of runways and the aerodrome elements normally associated with runways. These concerns include configuration, length, pavement bearing capacity, and other performance parameters relevant to current safety standards and the accommodation of foreseeable future runway needs.

The subsurface of the runway, ICAO 9157 notes, must be designed so that the nose gear of an airplane does not sink more than 15cm. Therefore, the subgrade’s bearing strength below the first 15cm must have a California Bearing Ratio (CBR) between 15 and 20%. Geogrids provide that safety and support for runways, just as they do for other intensive transportation applications such as high-speed railways.

Project Story: Berlin-Brandenburg International Airport

|

When Airbus and Boeing jets fly, their journeys must begin and end on a solid foundation, which includes essential support on the edges of runways. At the state-of-the-art Berlin-Brandenburg International Airport in Germany, NAUE Secugrid® geogrids are being used for primary stabilization and Carbofol® geomembranes for surface runoff protection.

The runways of the new Berlin-Brandenburg International (BBI) Airport cover an area of approximately 1,470ha. The design of the runways is quite complex. Runways are 60m wide but are complemented on both sides by a 75m wide strip, which is in turn divided into several functional areas.

Immediately next to the runway is an asphalt strip with shoulder and fire protection zones in which, among other things, runway lighting is installed. Surface water flows from the runway onto the paved shoulder, then directly into a vegetated wetland with coarse drainage sand for filtering elements such as de-icing agents, oils, fuels and more. These runoff collection zones (and the groundwater and soil beneath) are protected from seepage by 70,000m2 geomembrane, such as high-density polyethylene (HDPE) NAUE Carbofol® 508.

Also, the filter strip area must be extremely strong and stable, in case a plane veers off the runway. Preventing a more serious accident includes making sure the wheels do not sink too deeply into the vegetated strip. Also, these strips must support and allow quick, safe access for emergency personnel.

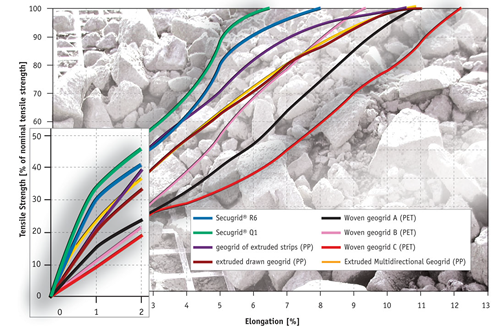

To stabilize the runway edges, Secugrid® 80/80 Q1 reinforcement geogrids were installed above the soil filter layer. Secugrid® is characterized by exceptional durability, high rigidity, and strong resistance to tensile forces, including at low elongation. These factors distribute stress quickly, effectively and safely to maintain runway integrity.

Approximately 280,000m2 of Secugrid® 80/80 Q1 were installed above the filter surface. Above the geogrid, a 30cm thick gravel layer was placed. Along with the runoff control, runway shoulder stabilization was installed. The nearly 500,000m2 of installed Secugrid® 30/30 Q1 made up the bulk of the geosynthetics supplied to the project by NAUE. This geogrid was laid on the prepared subgrade. Next came a 30cm thick gravel layer, 15cm of top soil and then vegetation.

Construction work was carried out by a consortium of Max Bögl, Eurovia VBU and Eurovia Beton. The collaboration was found to be both pleasant and professional.

The new, modern Berlin airport (opening June 2012) now has a transit network for airplanes, trains, metros and busses under one roof.

NAUE Solutions

|

Geosynthetics from NAUE are designed to meet the high environmental standards and performance requirements of today’s airport designs. Secugrid® geogrids, with their exceptional stress/strain characteristics, are ideal for subgrade stabilization beneath fluctuating, heavy loads. The high torsional stiffness of Secugrid® and the way the geogrid interlocks with aggregate provides greater resistance against twisting stresses.

Secugrid®’s high strength at low design elongations is vital to picking up stresses immediately and redistributing the load so that little or no movement occurs in the surface layer from which the stresses emanate. This is precisely what guidelines such as ICAO 9157 call for. Beyond subgrade stabilization, the subsoils in airport drainage zones must be protected from excessive seepage. Increasingly, geomembranes such as NAUE Carbofol® or geosynthetic clay liners (GCLs) like Bentofix® are utilized for primary and secondary containment of stormwater detention ponds, deicing pads, fuel tank farms and more. In the grassy strips between runways and

taxiways, geosynthetic containment technologies are even helping create sustainable wetlands. The design of the new Berlin-Brandenburg International Airport exemplifies how geosynthetics are being used in airports now.

Visit NAUE’s website at www.naue.com for more project stories and product information.