The protection of embankments and natural slopes from wind and rain erosion is one of the critical tasks in large-scale railway and road construction. Vegetation cover alone may be insufficient, since it is not always possible to achieve dense and uniform growth. This is especially true with larger slopes and in remote locations. Polypropylene anti-erosion geomats enable effective slope reinforcement while supporting strong vegetation.

This solution was used to protect the slopes of a railway line for the massive Amur gas processing plant, which is located along the Trans-Siberian Railway. When site construction is finished, the plant will support the processing of 42 billion cubic metres of gas per year.

GAS PROCESSING PLANT RAILWAY

The Amur gas processing plant is the largest Russian enterprise and one of the biggest facilities of its kind in the world. The current construction works have been conducted along the railway track between the Ust-Pera station and the plant.

The work has involved the construction and reinforcement of a 26-m-high embankment along a key stretch exceeding 50m in length. The railway section is specially designed to facilitate the transportation of equipment and materials to the gas processing plant. It also transports finished products from the plant.

To ensure the stability of these 9-story-high slopes against erosion, 640,000 m2 of reinforced geomats were installed. Maccaferri’s MacMat was specified.

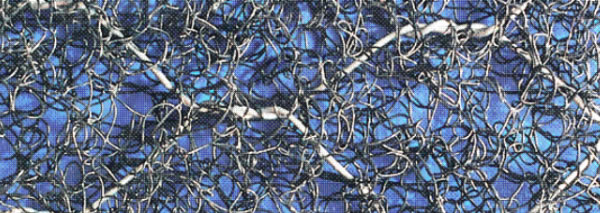

MacMat is a three-dimensional panel of entangled polypropylene fibers that form a highly elastic layer of high porosity. The structure enables plant roots to sprout through it while securing themselves to the mats. A complex, secure structure results, stabilizing the topsoil and giving the roots significant protection stabilize themselves deeply in the subsoil.

Considering the height of the slopes and the criticality of the railway line, reinforced geomats were used (MacMat R 6822 GO). This type utilizes double-twisted steel wire mesh to reinforce the mats while a special PVC coating protects the wire from chemical and biological degradation.

It’s an approach suitable not just to prepared slopes, such as for the gas processing plant railway line, but for rocky slopes and areas with landslide concerns.

The geomats were supplied in rolls for efficient deployment on site, once each roll’s quality and site suitability had been confirmed by laboratory control testing at Maccaferri’s facility in Zaraysk.

JSC NIPIGAZ handled installation, which, due to the roll’s lighter weight, was able to be conducted quickly and without any specialized equipment by a team of 4 – 5 people. Roll widths were able to be supplied in standard dimensions (2 m wide) to ensure quick coverage.

Depending on slope length and construction team size, up to 5,000 m2 of the geomat can be installed per shift.

YEARS OF GREEN SUPPORT

For germination of plant roots through the geomat, hydroseeding is used, once vegetation-supporting soil is applied. Installation in moderate temperatures ensures the quickest germination. Once installed and cover with soil, the geomat resists damage from frost and repeated freeze/thaw cycles; thus, giving vegetation many seasons of supporting.

For the Amur gas processing plant project, the use of reinforced geomats gives the site’s crucial railway water and wind erosion along the slopes, prevents leaching of seeds and topsoil, strengthens the root system, and improves soil adhesion.

Learn more about Maccaferri’s engineering solutions at www.maccaferri.com. See also, Maccaferri Russia’s pages on the Maccaferri global website.