|

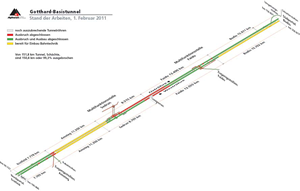

Construction of the New Rail Alpine Crossing (NEAT) project represents a further step in regard to Switzerland’s integration in the growing European high-speed network. The core is the Gotthard base tunnel, which at 35.4 miles will be the longest rail tunnel in the world. It will comprise two single-track tunnel tubes. Construction is simultaneously in progress on five partial sections of different lengths, so as to optimize the construction time and costs. The costs for this gargantuan project are estimated to be around 9.8 billion Swiss francs ($ 10.8 billion).

The construction time will total 20 years. The historic breakthrough of the tunnel occurred on October 15, 2010 and the grand opening is planned for 2016.

Future-oriented project

“AlpTransit” passenger trains will one day travel through the tunnel at 124 – 155 mph. Even with the traveling speed of 99 mph that is currently possible, the journey between Milan and Zurich will be reduced by an hour to two hours 40 minutes. Besides the familiar high-speed trains (TGV, ICE), modern tilting trains will be able to travel over the new sections at speeds of over 124 mph. Approximately 20 million people who live in the direct catchment area of the AlpTransit line will benefit from the shorter journey time. The entire project sets new standards in terms of planning, logistics, technology, ecology and financing. Following construction of the flat rail route, fewer locomotives, less personnel and energy will be required for the same amount of transport. This means that rail will once again represent a real alternative to road and air transportation.

A coordinated workflow is necessary

|

The heading is created with a tunnel boring machine or traditionally, with drilling and blasting. Afterwards, an external safeguarding shell is applied with shotcrete. This must fulfill the highest requirements for roughness and flatness. The drainage layer is applied onto the shotcrete. It is fastened onto the concrete with setting bolts. The exact spacing of the fastening points was determined in tests. Discs backed with hook and loop fasteners are fastened during the same work stage. These will later support the plastic sealing sheeting which is laminated with special felt.

The “Worm” has what it takes

The plastic sealing sheets are welded by a giant, 2 x 273 yard long monster, the so-called “worm.” It works around 79 ft a day through the tunnel. Running through its lower part are the supply lines for electricity, water and fresh air for the tunnel boring machine which is situated further ahead. The entire construction site traffic including excavated material and personnel also runs on rails below it. The "Worm" is also the location for testing the roughness and flatness of the shotcrete, applying the drainage layer and fastening the hook-and-loop fastener-backed discs. Afterwards, the plastic sealing sheets are unrolled with a special device and pressed onto the Velcro-backed discs.

Overhead welding made easy

|

The overlaps of the sheets are then welded tightly and permanently using the TWINNY S welding machines from Leister. This compact combination wedge device has proven its merits once more. Even overhead welding is possible as a result: the TWINNY S presses the two sheets together and thus rises easily and safely during welding. The welding progresses almost by itself. If required, the welding direction can be corrected simply and without interruption. The contact pressure, welding speed and temperature can be adapted to the relevant requirements. Despite its small dimensions, welding speeds of up to 6.5 ft per minute are possible with the TWINNY S, depending on the contact pressure. This is a crucial advantage when you consider the size of this project.

The tightness is the most important criterion when evaluating the weld quality. To guarantee the greatest possible safety here, a test channel is installed for each overlap weld. This is realised with the pressure roller on the TWINNY S which was specially designed for this purpose. This ensures two parallel weld seams of 0.6 inch each. The resulting test channel between these seams is 0.8 inch wide. The watertightness can be reliably monitored via compressed air using this channel.

Working in a confined space

The structural sealing acts as a shield protecting against penetration by mountain water. Drainage pipes collect the diverted moisture on both sides. This is held in the large, central collecting pipe and routed to the tunnel exits.

Waterstop profiles set in concrete on both sides in the kicker area (concrete base) complete the "rain shield." The rain shield seal is joined to the back of the waterstop here. This awkward work in a very confined space and on hard substrate is performed with the lightweight and practical semiautomatic welding machine TRIAC DRIVE from Leister.

Where necessary, a protection rail is mounted afterwards and finally a reinforcement installed. As a final step, the concrete inner shell of the tunnel is installed.

621 miles weld seams

|

The plastic sealing sheets for the south side and center of NEAT are produced in the Sika plant in Duedingen, Switzerland with a width of 2.40 yards. Two overlapping sheets are prefabricated here. As a result, a circumferential weld seam of 26 yards is only necessary approximately every 14 ft for processing in the tunnel. This includes the two-sided weld seams on the base seal and the weld seams for the countless cross connections of the two tunnel tubes. In total, this corresponds to a weld seam length of around 621 miles for the entire, 35.4 mile long Gotthard tunnel! The sheet fabrication, cutting to length and delivery of the plastic sealing sheets are each adapted to the construction section.

Quality is crucial

On account of the permanent shift operation and the special parameters, a high level of dust, heat and air humidity arises in the tunnel. Only the best quality of material, processing and machine enables fault-free and hence efficient work. With a planned service life of over 100 years, there are different requirements in play than those typical of standard structures.

All products used for the sealing system therefore had to prove their suitability for this extraord

inary project during long tests. The selection of the materials was also accompanied by regular monitoring, thereby ensuring that the quality and processing remain within a defined tolerance range. The specialists at the accredited test institute, Tecnotest AG in Rueschlikon, Switzerland are relied on for this process. Control inspections concerning the drainage and sealing are conducted in the laboratory. In addition, the company inspects the quality of the weld seam and the substrate on site. Regular peel tests to check the weld quality are carried out directly in the tunnel using the EXAMO test device from Leister, a device highly suitable for construction sites. The plastic sealing sheets and the drainage layer undergo further tests in the laboratory in order to test the various material properties.

Long-term project

|

Read Leister’s interview with Sika AG’s Urs Streuli regarding the New Rail Alpine Crossing (NEAT) project. |

The flat rail route opens up new dimensions in passenger and goods transportation. Economic centers on both sides of the Alps will be brought closer together. The railway will become a modern and powerful instrument of transportation on the North-South axis thanks to “AlpTransit.” It will be able to provide greater transport capacity with shorter traveling times. Furthermore, it will guarantee an environmentallyfriendly, sustainable solution for issues of mobility and the continually growing volume of traffic. An incredible amount of work has gone into this project for the future. The quality of this construction of the century is therefore extremely important.

Not only is the processing and the material crucial, but also the machinery used. Leister shares the responsibility for this thanks to the use of its welding machines and hot-air hand tools. Even under these exceptional conditions in the tunnel, the equipment of the long-established Swiss company is once again proving its merit. After all, the sealing system must continue to fulfil its purpose for 100 years’ time!

In total, 94.4 miles of tunnels, shafts and galleries are excavated. Around 621.4 miles of seams are then welded.

Christophe von Arx Leister Process Technologies, www.leister.com. Norbert Tholl works for TechnoTest AG, www.tecnotest.ch.

|

Construction customer: AlpTransit Gotthard AG |

Learn More: An Interview

Learn More: An Interview PROJECT DETAILS

PROJECT DETAILS