By José Miguel Muñoz Gómez – High-density polyethylene liners are renowned for containment performance in landfills, mining, wastewater, and other vital sectors. Less discussed but meriting evaluation is the superior carbon footprint rating that HDPE geomembranes provide versus traditional barriers like compacted clay.

A 1.5mm (60-mil) HDPE liner can provide a seal similar to 0.6m of high-quality, homogeneous compacted clay and yield a permeability lower than 1 x 10‐11 m/sec (per ASTM D 5887). The HDPE geomembrane subsequently exceeds overall impermeability and sustainability measures when one examines the full scientific record, with consideration of all resources and energy in the production of clay and HDPE geomembranes to be used as a barrier layer.

The geosynthetic approach provides, as the data show, a more environmentally friendly solution.

CARBON FOOTPRINT & HDPE GEOMEMBRANE FEATURES

The main component of HDPE is the monomer ethylene, which is polymerized to form polyethylene. The main catalysts are aluminum trialkylitatanium tetrachloride and chromium oxide

The polymerization of ethylene and co‐monomers into HDPE occurs in a reactor in the presence of hydrogen at a temperature of up to 110° C (230° F). The resulting HDPE powder is then fed into a pelletizer.

SOTRAFA utilizes a calandred system (flat die) to make its primary HDPE geomembrane (ALVATECH HDPE) from these pellets.

GHG Identification and CO2 Equivalents

The greenhouse gases included in our carbon footprint evaluation were the primary GHGs considered in these protocols: carbon dioxide, methane, and nitrous oxide. Each gas has a different Global Warming Potential (GWP), which is a measure of how much a given mass of a greenhouse gas contributes to global warming or climate change.

Carbon dioxide is by definition issued a GWP of 1.0. To quantitatively include the contributions of methane and nitrous oxide to the overall impact, the mass of the methane and nitrous oxide emissions are multiplied by their respective GWP factors and then added to the mass emissions of carbon dioxide to calculate a “carbon dioxide equivalent” mass emission. For purposes of this article, the GWPs were taken from the values listed in the 2010 US EPA guidance “Mandatory Reporting of Greenhouse Gas Emissions.”

The GWPs for the GHGs considered in this analysis:

- Carbon Dioxide = 1.0 GWP 1 kg CO2 eq/Kg CO2

- Methane = 21.0 GWP 21 Kg CO2 eq/Kg CH4

- Nitrous Oxide = 310.0 GWP 310 kg CO2 eq/kg N2O

Using the relative GWPs of the GHGs, the mass of carbon dioxide equivalents (CO2eq) was calculated as follows:

kg CO2 + (21.0 x kg CH4) + (310.0 x kg N2O) = kg CO2 eq

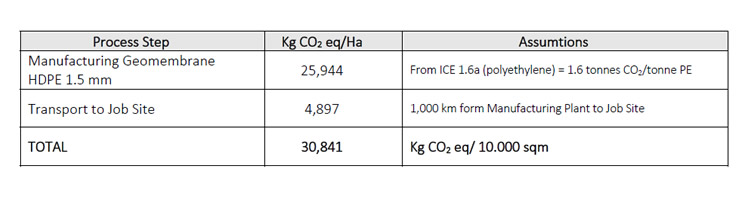

Assumption: The energy, water, and waste information from the extraction of the raw materials (oil or natural gas) through production of HDPE pellets and then manufacturing geomembrane HDPE:

- 5 mm thick HDPE geomembrane, with density 940 Kg/m3

- HDPE carbon footprint is 1.60 Kg CO2/kg polyethylene (ICE, 2008)

940 Kg/m3 x 0.0015 m x 10,000 m2/ha x 1.15 (scrap and overlaps) = 16,215 Kgr HDPE/ha

E = 16,215 Kg HDPE/Ha x 1.60 Kg CO2/kg HDPE => 25.944 Kg CO2 eq/ha

Assumption Transport: 15.6 m2/truck, 1000 km from manufacturing plant to jobsite

- 15 kg CO2/ gal diesel x gal/3,785 liters = 2.68 Kg CO2 /liter diesel

- 26 g N2O/gal diesel x gal/3,785 liters x 0.31 kg CO2 eq/g N2O = 0.021 kg CO2 eq/liter diesel

- 44 g CH4/gal diese x gal/3,785 liters x 0.021 kg CO2 eq/g CH4 = 0.008 kg CO2 eq/liter diesel

1 liter diesel = 2.68 + 0.021 + 0.008 = 2.71 kg CO2 eq

On‐Road truck product transport emissions:

E = TMT x (EF CO2 + 0.021∙EF CH4 + 0.310∙EF N2O)

E = TMT x (0.972 + (0.021 x 0.0035)+(0.310 x 0.0027)) = TM x 0.298 Kg CO2 eq/ton‐mile

Where:

E = Total CO2 equivalente emissions (kg)

TMT = Ton Miles Traveled

EF CO2 = CO2 emission factor (0.297 kg CO2/ton‐mile)

EF CH4 = CH4 emission factor (0.0035 gr CH4/ton‐mile)

EF N2O = N2O emission factor (0.0027 g N2O/ton‐mile)

Converting to Metric Units:

0.298 kg CO2/ton‐mile x 1.102 tons/tonne x mile/1.61 km = 0,204 kg CO2/tonne‐km

E = TKT x 0,204 kg CO2 eq/tonne‐km

Where:

E = Total CO2 equivalente emissions (Kg)

TKT = tonne – kilometers Traveled.

Distance from Manufacturing Plant (Sotrafa) to Job Site (Hypothetical) = 1000 km

- Typical Loaded truck weight: 15,455 kg/truck + 15.6 m2 x 1.5 x 0.94/truck = 37,451 kg/truck

- 641 truck/ha

E = (1000 km x 37,451 kg/truck x tonne/1000 kg x 0.641 truck/ha) x 0.204 kg CO2 eq/tonne‐km =

E = 4,897.24 Kg CO2 eq/ha

FEATURES OF COMPACTED CLAY LINERS AND ITS CARBON FOOTPRINT

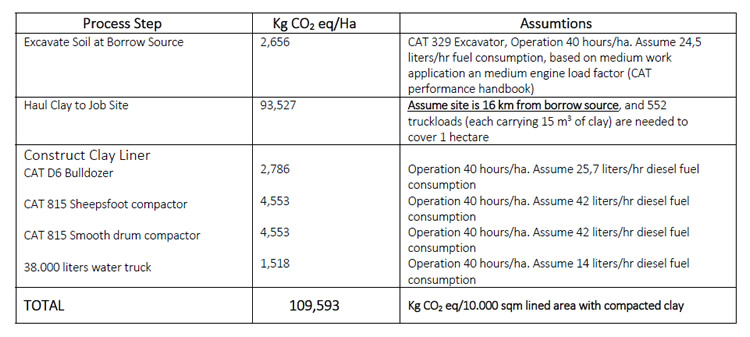

Compacted clay liners have been used historically as barrier layers in water lagoons and waste containment facilities. Common regulatory requirements for compacted clay liners are a minimum thickness of 0.6 m, with a maximum hydraulic conductivity of 1 x 10‐11 m/sec.

The process: Clay at the borrow source is excavated using standard construction equipment, which also loads the material onto tri‐axle dump trucks for transport to the job site. Each truck is assumed to have a capacity of 15 m3 of loose soil. Using a compaction factor of 1.38, it is estimated that over 550 truckloads of soil would be needed to construct a 0.6m thick compacted clay liner over a one‐hectare area.

The distance from the borrow source to the job site is, of course, site‐specific and can vary greatly. For the purposes of this analysis, a distance of 16 km (10 miles) was assumed. Transport from the clay borrow source and the job site is a large component of the overall carbon emissions. The sensitivity of the overall carbon footprint to changes in this site‐specific variable is explored here.

CONCLUSION

While HDPE geomembranes will always be selected for performance before carbon footprint advantages, the calculations utilized here once again support the use of a geosynthetic solution on grounds of sustainability versus other common construction solutions.

Geomembranes such as ALVATECH HDPE 1.5 mm will be specified for their high chemical resistance, strong mechanical properties, and long-term service lives; but we should also take time to recognize that this material offers a carbon footprint rating that is 3x lower than compacted clay. Even if you evaluate good quality clay and a borrow site just 16 km from the project site, HDPE geomembranes coming from 1000 km away still outperform compacted clay on a measure of carbon footprint.

José Miguel MUÑOZ GÓMEZ is a Product Manager in the Geosynthetics Division of Sotrafa S.A. Learn more about the company’s geomembranes, engineering applications, sustainability resources, and more at www.sotrafa.com.

MORE SUSTAINABILITY STORIES ON GEOSYNTHETICA