Constructing on weak subgrade is always a challenge, but geosynthetics provide high-quality, efficient, and economical solutions. An exemplary case can be found in the busy city of Kolkata, India, where a logistics company needed to improve a weak subgrade at the site of a new container yard. Geocells provided the answer.

ALLCARGO LOGISTICS Ltd.’s container yard was to be located at Kidderpore Dock. The zone was planned for transit storage heavy containers, which would be stacked five-high. The subsoil included 7 – 8 meters of riverine deposits, comprising of soft clay topped by about 3m of heterogeneous fill.

CHOOSING AN ENGINEERING STRATEGY

A container yard typically has two major issues, each of which impacts construction decisions and long-term maintenance:

- Heavy pressures from container stacks

- Non-uniform settlements of the ground

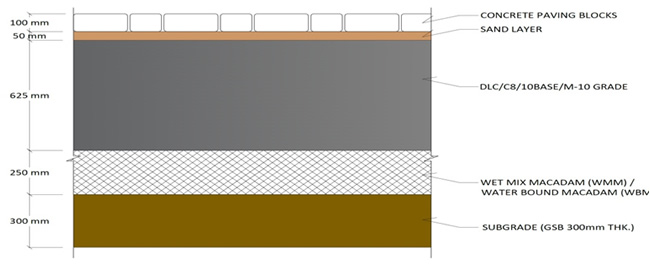

The typical approach to improving this type of site would involve subsoil consolidation through the installation of prefabricated vertical drains (PVDs) and preloading the area with placement of a surcharge. This is a slow process that requires close monitoring of settlements as the surcharge is placed in stages. Surcharging usually involves large quantity of earthwork to progressively achieve the final load, often equivalent to the load to be transferred from the loading system.

To achieve the appropriate bearing capacity for each surcharge stage and support the very heavy loads for the service life of the proposed container yard site, significant earthworks and time would have been required in Kolkata. It was considered too time and cost-intensive.

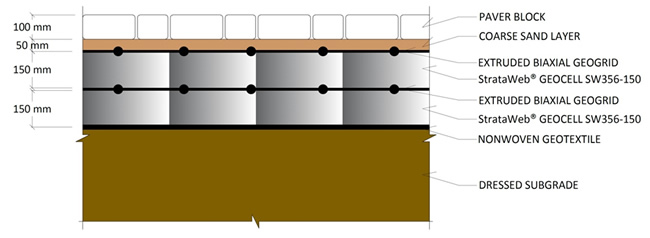

Strata’s geotechnical specialists proposed a geocell-centered design that could be efficient to construct and even eliminate a concrete layer.

The StrataWeb® system utilized for the container yard incorporated the geocell layer within the paving to reduce the bearing pressures on the subsoil. This provided a thinner pavement design without sacrificing bearing capacity or safety. Combined with the easy-to-place infill, the StrataWeb® system addressed the differential settlement issues and provided an even working ground.

CONTAINER YARD ENGINEERING DESIGN

The engineering analysis demonstrated that the imposed pressures with a section reinforced with StrataWeb® SW 356-150 (Weld spacing 356 mm; cell depth 150mm) would be well within the safe bearing capacity of the subgrade. The design included two layers of the geocell to bear the load spread. The geocell was infilled and topped with 10mm of down-graded gravel. A layer of StrataBase® geogrid was included to further strengthen the section and improve the performance.

PROJECT TAKEAWAYS

For the new Kolkata container yard to opt for the geocell design, a number of added value was realized:

- Saved up to 15% of the cost compared to conventional methods

- Rapid installation due to the easy transportation of the geocells

- Use of locally available, cheaper materials

- Increased life span with lower maintenance

- Load spread ensured that bearing pressures were within safe limits

- Uniform settlements and even working ground

For more information about StrataWeb® geocell systems, reinforcement geosynthetics, and more, visit Strata Geosystems’ website, www.strataindia.com.

KOLKATA CONTAINER YARD PROJECT DETAILS

Location: Kidderpore Docks, Kolkata, India

Principal Client: ALLCARGO LOGISTICS Limited

Consultant: Shanghvi and Associates Consultants Pvt. Ltd.

Application: Paved area to support five-container high stacks

System Offered: Paved section incorporating StrataWeb®