By Terre Armée – In order to support the significant production increase at the Cerro Verde copper mine, Tierra Armada Perú was requested by the owner, Sociedad Minera Cerro Verde S.A.A. (SMCV), to design and supply the specific components for two 34-meter-high mechanically stabilized earth walls to support two primary crushers. The walls needed to facilitate the maneuvers for dump trucks weighing approximately 700 tons.

Both walls were built in record time with design, technical assistance, and material supply provided by Tierra Armada Perú. They utilized the GeoTrel™ system and in the process created the tallest GeoTrel™ walls in the world.

GeoTrel™ walls are Reinforced Earth® walls composed of reinforcing geosynthetic strips (geostrips) connected to a segmental facing made of high-quality wire mesh panels. These walls also belong to the short list of 30+ m high walls built in one single tier.

This MSE system was selection by the client for two large platforms supporting heavy trucks transporting ore mineral obtained from excavations to crushers N°1 and N°2 before being processed.

For primary crusher No.1, the two wings are formed by Walls 1 and 2. The left wing Wall 1 has a length of 22m and a maximum height of 34m immediately adjacent to the copper mine crushers building. The right wing formed by Wall 2 has a length of 49m, also with a maximum height of 34m, next to the crusher building then tapering down to a height of 7.5m.

For primary crusher No.2, the retaining structures consist of two wing walls formed by Walls 3 and 4. Wall 3 has a length of 66m and a trapezoidal height at a maximum of 34m next to the crusher then reducing down to a height to approximately 14m. The right side formed by Wall 4 has a length of 36m.

In total, the project represents 4,400m² of GeoTrel™ walls composed of wire facing reinforced using the geosynthetic strips known commercially as GeoStrap®.

COPPER MINE CRUSHERS: MSE WALL PROPERTIES

Tierra Armada Perú conducted both external (e.g, bearing pressure, direct sliding and eccentricity) and internal (e.g., tensile strength and pullout) stability analyses in accordance with AASHTO LRFD standards. Also consistent with AASHTO requirements, a selected granular backfill material with less than 15% fines was used. The design incorporated a significant seismicity requirement considering a Peak Ground Acceleration (PGA) of 0.51g over a return period of 500 years. A dynamic stability analysis was performed using pseudostatic methods for both walls and nearby slopes considering a horizontal seismic coefficient equal to a half of the PGA.

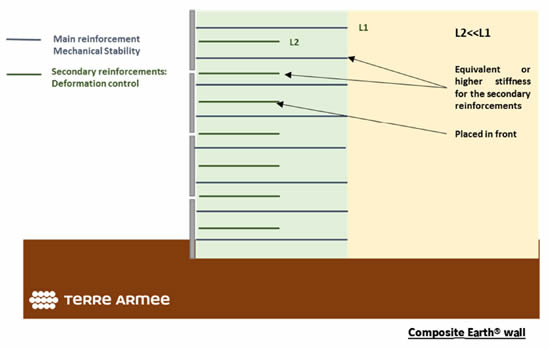

In the present case, due to the extreme height of the structure and its criticality, the reinforced fill was further stiffened by the use of additional layers of reinforcements not connected to the facing, both in the form of geostrips and geogrids. This Composite Earth® layout1 takes into account the fill reinforcement necessary to get strict stability of the structure by controlling global and local deformations, in spite of the use of relatively extensible reinforcements.

The GeoTrel™ walls were designed considering a galvanized wire-mesh facing, backed with stone, and connected by a metallic assembly to polymeric geosynthetic strips as reinforcement. The main polymeric reinforcing strips used for reinforcement were 50 mm wide GeoStrap® with an ultimate tensile strength of 65kN and secondary polymeric strips using 90 mm GeoStrap® with an ultimate tensile strength of 100kN.

GeoStrap® is composed of high tenacity polyester with a polyethylene sheathing that combines both high tensile strength and pullout resistance.

The GeoTrel™ construction method is similar to that of traditional Reinforced Earth® structures. The system allows retaining structures to be constructed in chemically aggressive environments (corrosive backfilling materials, recycled aggregates, pollution risks, infiltration of de-icing salts, etc.).

MSE WALL EXPERIENCE

Reinforced Earth® earth solutions and structures are part of the specialized engineering and design departments of the companies of Terre Armée group. These companies offer their customers tailor-made solutions using proven methods. The resulting structures combine engineered granular fill, tensile reinforcements and modular facing panels to create efficient load bearing, mass gravity retaining walls to any practical height. Reinforced Earth® structural design is in compliance with current national and international standards.

For more than 50 years, our clients have entrusted the teams of experienced engineers and project managers to deliver time-critical infrastructure solutions that are vital for the long-term commercial sustainability of their multibillion dollar investments.

Terre Armée Group has a presence in all five continents and has the advantage of both local and international expertise. This wealth of expertise, has led the company to develop processes offering common advantages:

- Reliable and sustainable materials

- Savings in terms of time and resources

- Capacity to adapt to complex situations

- Integration into the environment, in particular due to an extensive range of panel finishes

Learn more about Terra Armée’s engineering solutions and services, including copper mine crushers, gravity retaining walls, transportation engineering, and much more at www.terre-armee.com.

1 Solution Protected by Patent Right

**

See also: