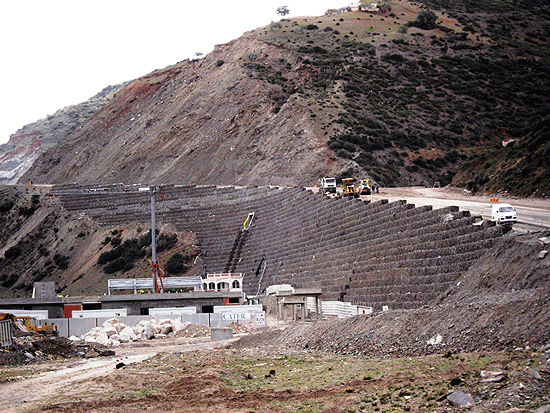

In this two-part article, Alain Hérault, Sabihi Abdelhak, and Chakib El Iraki write on the new French standard NF P 94-270 and how it establishes design rules for the use of geosynthetics and other reinforcing materials in reinforced earth walls and steep slope applications. These rules, based on the partial factors defined in Eurocode 7 (EN 1997), were applied to a huge Mediterranean bypass project in Morocco to determine tensile strengths, lengths and spacing of geogrids. In Part 1, the authors address the project context, Eurocode framework, and installation and durability issues.

|

DESIGN

External stability

Two project scenarios were considered – sustainable and seismic. The seismic scenario was studied through a pseudo-static approach using the Mononobe-Okabe method. The reference maximum acceleration considered for the Rif site zone was 2.2 m/s2.

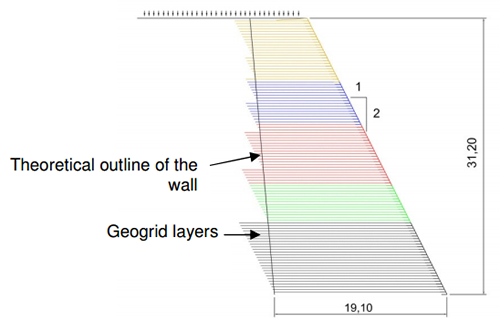

Firstly, we have to define the theoretical outline of the reinforced earth structure. We are thus led to consider one or more fictitious planes that follow the ends of the reinforcing layers or, for simplicity and to be more conservative, those furthest from the facing, which cut through all of the layers. The second of these two options was chosen for the walls of the Mediterranean bypass (Fig. 1).

|

The external stability was verified by considering the coefficients of approach 2 of Eurocode 7 and an inclination of the earth pressure at the back of the wall of 2/3 φ.The dimensions of the foundation walls were defined according to the bearing capacity of the foundation soil layers.

Internal stability

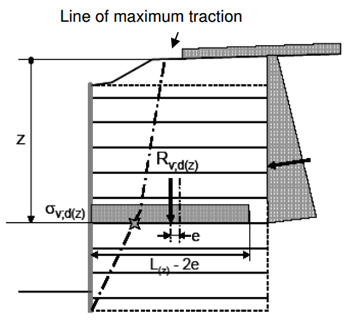

This design step consists of verifying, for each reinforcing layer of the wall section considered, the long-term design strength of the geogrid Rt;d mentioned above, the strength of the soil/geogrid interaction and the stability of the gabion facing. The stresses are assessed for each reinforcing layer (Fig. 2), taking into account the partial factors on the loads and effects of the loads according to the combination of loads studied.

|

The internal stability was verified following approach 2 of EC7.

Compound Stability

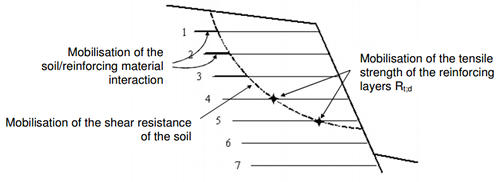

The next step is to check that there is no risk of sliding failure along the surfaces that intersect or run alongside at least one reinforcing layer (Fig. 3). It was checked using a calculation model based on the standard “Bishop” method, by considering the coefficients of approach 3 of Eurocode 7, in this case with a partial factor of 1.25 on the shear characteristics of the soil (φ, c) and a model partial factor γS;d of 1.10.

|

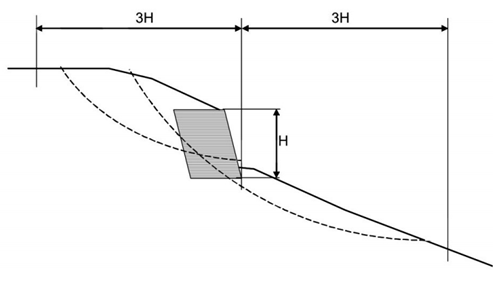

This stability calculation generally relates only to a zone that extends to horizontal distances of +/- 3H from the foot of the wall (Fig. 4).

|

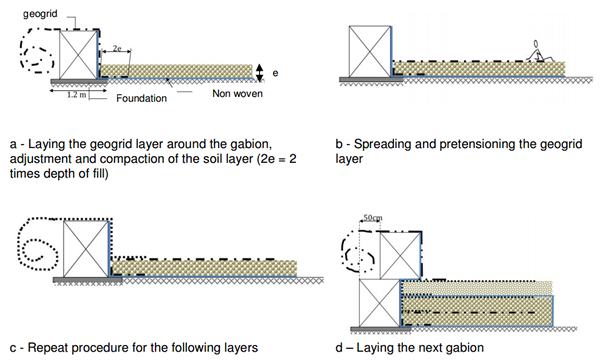

INSTALLATION PROCEDURE

The gabion facing inclined at 63° is used as permanent formwork for the compaction of the fill layers (Fig. 5).

|

QUALITY MANAGEMENT

Colbond’s geogrid production is ISO 9001:2000 certified. Internal production control is carried out by Colbond bv and supervised by the tBU – Institut für textile Bau – und Umwelttechnik GmbH, Greven/Germany during the yearly CE audit.

On-site quality control requires specific validation of each fill layer after checking its density, which must be higher than 95% of the OPM (Proctor compaction test), as well as a topographic check. The laying of the geogrids is subject to validation by visual inspection with a written report for each layer consisting of:

- Step number

- Section number (4.80m in width)

- Geogrid class (tensile strength)

- Length of lower anchorage

- Length of upper anchorage (conform/not conform)

- Status of the geogrid layer (conform/not conform)

|

CONCLUSION

As for Construction and Civil engineering activities, Geotechnical works have also become part of the European regulatory framework of Eurocodes that establish a semi-probabilistic approach to safety through a number of partial factors common to all construction trades.

To increase trust and credibility, it was considered desirable for geosynthetics to be integrated into this development quickly.

The French design standard NF P 94-270 now provides all designers of reinforced earth walls with a design tool, in accordance with the Eurocodes, which will allow them to specify and validate their design choices. It will also help them during the technical evaluation of the solutions proposed by companies.

This was certainly the case during the review of the technical proposals for this major “Mediterranean Bypass” project in Morocco.

However, accurate calculation methods must go hand in hand with good on-site practices during construction.

REFERENCES

- NF P 94-270. Design standard, Calcul géotechnique – Ouvrages de soutènement – Remblais renforcés et massifs en sol cloué. AFNOR, France

- NF EN ISO 10319. Standard test method, Geosynthetics – wide-width tensile test. AFNOR, France

- NF EN 1990/A1. Design standard, Eurocode – Basis for design – Part 1: General Rules – National annex to NF EN 1990/A1 : 2006. AFNOR, France

- NF EN 1997-1. Design standard, Eurocode 7 – Geotechnical design – Part 1: General Rules. National annex to NF EN 1997-2005. AFNOR, France

- ISO/TR 20432. Standard, Guidelines to determination of long term strength of geosynthetics for reinforcement

Alain Hérault is a Product Manager with Bonar Geosynthetics, France; Sabihi Abdelhak is a Quality Manager for Arab Contractors-Houar-Elhajji-Lrn-Seprob; and Chakib El Iraki is the Public Works and Environment Department Manager for Valtech.