Geosynthetic barriers perform exceptionally well in liquid containment applications, but gas barrier performance can still be improved. Volatile organic compounds, for example, can diffuse through barrier systems. The rate is low, but the incorporation of an EVOH layer in a geomembrane has shown that the diffusion rate of VOCs can actually be much lower.

Applications that utilize geosynthetics and can benefit from better gas barrier performance include:

- Landfill capping

- Landfill gas cover systems

- Underslab VOC, radon, and methane barriers

- Remediation covers (e.g., brownfields)

- Interim landfill covers

- Odor control barriers

- EPS geofoam protection

BETTER GAS BARRIER PERFORMANCE IN GEOSYNTHETICS

Ethylene vinyl alcohol (EVOH) is part of the polyethylene family. It can be easily co-extruded with materials like linear low-density polyethylene (LLDPE), high density polyethylene (HDPE), and polypropylene. EVOH is a polar molecule, making it a strong barrier to non-polar contaminants like VOCs. Since polyethylene is a great barrier to liquids, the incorporation of EVOH with PE leads to some exceptional performance properties.

For example, VOC migration through an EVOH-enhanced 25-mil geomembrane has been found to be more than 80 times less than through a conventional 60-mil HDPE geomembrane. Furthermore, the liquid containment performance of the geomembrane is not altered by the EVOH.

The scalability of the EVOH solution to blocking the upward migration of harmful gases has seen it applied broadly, from thin vapor retarders in commercial and residential construction to more advanced, thicker geomembrane gas barrier performance applications.

Two international manufacturers offer 7-layer geomembranes with an EVOH core: Raven Industries and Plastika Kritis.

EVOH IN GEOMEMBRANES

Raven Engineered Films

Raven was the first company to commercialize a geomembrane with an EVOH gas barrier performance layer. In 2011, the company installed a large, state-of-the-art line with the capability to produce seven-layer barrier materials up to 80 mil thicknesses.

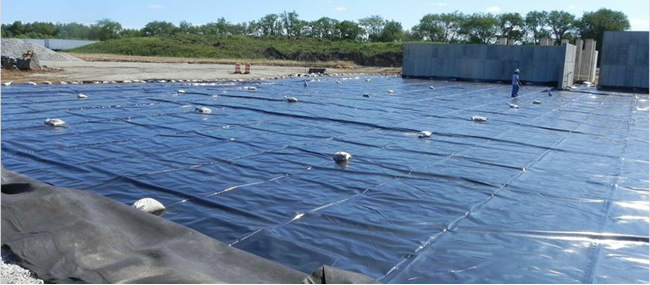

ABSOLUTE BARRIER® geomembranes are engineered for the superior containment of hazardous contaminants in gas, odor, liquid, and solid form. The ABSOLUTE BARRIER® X Series products offer a range of HDPE options (e.g., smooth or textured, standard 40 and 60-mil thicknesses, etc.) and have been designed particularly for use in MSW landfill covers, caps, and impoundment containment covers. The Y Series products focus on LLDPE geomembranes. They are engineered to stop gas vapor migration on brownfield sites and in residential and commercial buildings, as well as being part of general geomembrane containment and cover systems.

Both series utilize EVOH for enhanced gas barrier performance by the geomembrane.

Learn more about Raven’s geosynthetic barriers.

Plastika Kritis

Plastika Kritis is known internationally for its Kritiflex® geomembranes, and as the next phase for its geomembrane growth it added 7-layer co-extrusion manufacturing technology. This has enabled it to produce geomembranes with a thin EVOH layer. The product widths in Plastika Kritis’s True Gas Barrier Geomembrane line range from 2 to 10m (6.5 to 33 ft.).

These EVOH-enhanced geomembranes are available in HDPE and LLDPE constructions. Special polyolefin alloys and compounds can be used to impart strength and flexibility.

With the various film widths, the company has found application for seven-layer membranes in silage barriers, greenhouses, soil fumigation, geomembrane containment (e.g., landfill caps), and flexitanks and container liners.

Learn more about Plastika Kritis’s overall geosynthetics expertise.