By Ian D. Peggs – Due to wide variations in interpretation, the term Film Tearing Bond (FTB) for qualifying welded geomembrane seams has almost disappeared from the geomembrane lexicon. It essentially disappeared from the waste containment sector several years ago, but it still remains in the potable water sector. It has been replaced by more precise descriptions of the location of specimen break, the degree of ductility, and the allowable amount of peel separation.

By Ian D. Peggs – Due to wide variations in interpretation, the term Film Tearing Bond (FTB) for qualifying welded geomembrane seams has almost disappeared from the geomembrane lexicon. It essentially disappeared from the waste containment sector several years ago, but it still remains in the potable water sector. It has been replaced by more precise descriptions of the location of specimen break, the degree of ductility, and the allowable amount of peel separation.

“A failure in the ductile mode of one of the bonded sheets (or one ply if the geomembrane is a reinforced laminate) by tearing prior to complete separation to the bonded area.”

Do we really want to see a “tearing” break? Or do we want to see a tensile break? Or is peel separation a “tearing” break? What does “complete separation to the bonded area” mean? Along the weld interface? Does something separate until it meets the “bonded area?”

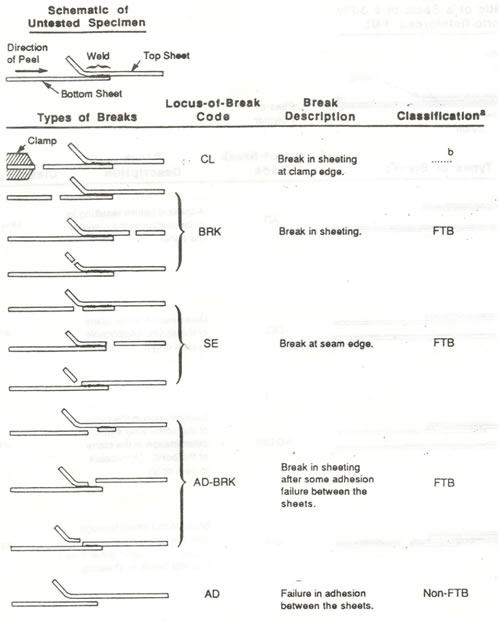

Locus-of-break diagrams from the 1993 version of NSF 54 and schematics of FTB breaks are shown in Figure 1. Note that in 1993, NSF made a note on the definition of film tearing bond that:

“The potential elimination of the term FTB is under discussion for possible future revisions to the Standard.”

Referring to BRK breaks in Figure 1, where the break occurs outside the edge of the weld, such breaks are defined as FTB. However, according to the definition, such breaks are not FTB breaks if they are not in a “ductile mode.” Where is the critical transition from non-ductile to ductile – 5, 10, 25, 100, or 300% elongation? FTB does not consider this, but newer specifications do. For instance, GRI.GM19 requires 50% for HDPE, LLDPE, and fPP, but has a “not-applicable” for RPP.

The same comments apply for SE breaks – ductile breaks will be classified as FTB but brittle breaks should not.

The situation becomes more complex with the AD-BRK classification, also described as FTB. The schematics show that some peel separation is allowed within the FTB designation. But how much – 5, 25, or 95%? If the final break is through one of the sheets in a ductile mode (how ductile?) then a 99% peel separation would be classified as FTB, but I doubt it would be acceptable to CQA people and even to most installers. In this case, film tearing bond is quite subjective, but GRI.GM19 is quite clear that separation shall not exceed 25% on an area basis. Again, in GRI-GM19, peel separation is considered “not-applicable” to RPP, but we will revert to that.

Clearly there is no argument that an AD break (complete interface separation) is non-FTB, at least in unreinforced materials. Some comments on reinforced materials will follow.

As an example of the confusion that can occur, a recent draft standard required that seams should be sufficiently strong that:

“… failure of a seam occurs outside the bonded region in a ductile manner. Seam failure should be a film tearing bond.”

Thus in one sentence it is required that failure occur outside the weld (AD-BRK, even ductile, is not acceptable), but in the next sentence failure inside the weld (AD-BRK) is allowed.

Clearly, the deficiencies in the definition of FTB were the reasons for its demise in the heavily regulated, need-for–precise-specification, waste containment sector. However, the potable water sector is keen to retain the still-used FTB terminology as an indicator of an acceptable geomembrane seam, whether for bottom liners (typically an unreinforced geomembrane) or for floating covers (typically a reinforced geomembrane). Therefore, the only way to do this effectively would be to redefine FTB. So, for discussion purposes, let me propose the following:

For unreinforced materials:

“Complete break at or outside the edges of the welded area. For shear tests, break must be in a ductile mode. For peel tests, brittle breaks at the edges of the welded areas are acceptable.”

For reinforced materials:

“For shear tests, complete break at or outside the edge of the welded area. For peel tests, break outside the edge of the welded area and/or partial or complete ply/scrim separation, but with no more than 25% area separation on the welded interface.”

Note: Minimum shear and peel strength values, minimum shear elongation values, and maximum peel separation values must be defined in the project specification. However, note that if acceptable parameters are required in the specifications, there is no further need for the FTB descriptor. The numbers alone define acceptance.

These definitions allow the occasional “snapping” (brittle break) that occurs in the lower sheet of thicker HDPE seams under the center of an extrusion seam. They also allow up to 25% interface peel separation on reinforced material seams (usually not HDPE in which avoiding seam separation is important) but require the bulk of the separation to be on the weakest scrim/polymer interface. Note that the welded interface should have the same strength as the internal strength of the polymer layer.

Other reasons for the demise of film tearing bond is that we are not dealing with “films” that are typically considered to have thicknesses less than 20 mil (0.45 mm). Nor are we dealing with tear-type breaks. Seam specimens are cut to generate tensile breaks so that shear and peel strengths can be compared with the material’s uniaxial tensile yield or break strengths, not its trapezoidal tear strength.

Yet another reason for FTB’s disappearance was that it was thought to be the project engineer’s responsibility to define an acceptable seam in terms of quantified parameters as a function of the criticallity of the project rather than to use an unquantified generic standard with no consideration of the specific application. A seam in a hazardous waste pond liner should surely be more reliable than one in a decorative pond liner. Subsequently, engineers felt that seam quality could better be described in more detail as per the GRI-GM19 standard.

In summary, the NSF 54 definition of FTB is not adequate to define acceptable seam quality. In the heavily regulated waste containment sector it has been banished and replaced with more clearly defined strength, shear elongation, and peel separation criteria. If it is to be retained by the potable water sector, it is necessary to change the definition to ensure that seams considered unacceptable by a large user population are not unwittingly approved. New definitions for unreinforced and reinforced geomembrane seams have been proposed for discussion purposes.

However, having now provided new definitions, I propose that we do not use them and that we forever banish film tearing bond.

Dr. Ian D. Peggs, P.E., P.Eng is president of I-CORP INTERNATIONAL, www.geosynthetic.com.