By Namrata Bichewar – As India has grown in population and economic influence, the country’s airport infrastructure has been strained. The existing Mumbai Airport, in particular, has been in need of greater support to handle the passenger and cargo traffic. For decades, a new airport was discussed. Finally, a proposal led by City and Industrial Development Corporation (CIDCO) put in motion the construction of Navi Mumbai International Airport.

The greenfield site, located on the banks of Gadhi River near Panvel Creek, is still under construction. Roughly 1600 hectares of land are being reclaimed in this river basin zone and the river itself is being trained along the airport premises to retain backfill soil material on the upstream side. The strategy will help protect the airport from flooding during heavy monsoons and drawdown during the dry season.

Siting the airport along this waterway is not an easy endeavor. Gadhi River is the main river of the Panvel creek and has a hard rock bedding surface. The adjacent development of industrial and residential land in Panvel City forces stormwater from Thanecreek into the Gadhi waters, causing water level surges.

In July 2005, for example, the river had an HFL (high flood level) of 6.5 m. Thus, a safe-grade elevation of 9m from bed rock level was proposed for Navi Mumbai International Airport.

The make it work, a retaining wall was needed to train the river along the Panvel creek.

REINFORCED SOIL WALL – COMPOSITE SYSTEM

Based up the site conditions and project needs, the engineering team opted for a reinforced soil wall that would provide a sustainable, environmentally friendly face to the perimeter infrastructure. The composite design used a reinforced soil wall with gabions as fascia—an extremely effective approach for land reclamation and river training projects.

RELATED: PVDs for Soil Improvement: Projects in Egypt and Mexico

A high-strength polyester uniaxial geogrid (Tech Grid (TGU) from TechFab India) was selected as the reinforcing element. TechFab Metal Gabion was chose for the fascia. The gabion featured GI wire mesh with a special coating of zinc90%+Al10%+ PVC coating to ensure the facing was durable against the annual fluctuations in sun and rain exposure. The system also ensured strong protection against erosion to protect the backfill material.

DESIGN & CONSTRUCTION NOTES

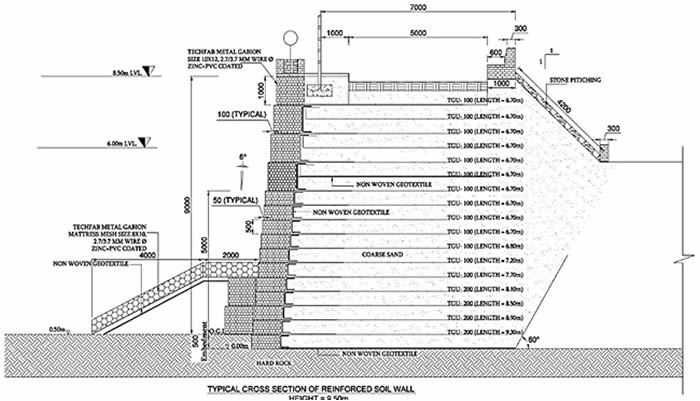

The reinforced soil wall was designed using BS 8006 design standards. The gabion mattresses were installed with a height of 2.5m from the hard rock level to prevent inundation and sliding at the toe of the retaining wall. The maximum height of reinforced soil wall was 11.5 m.

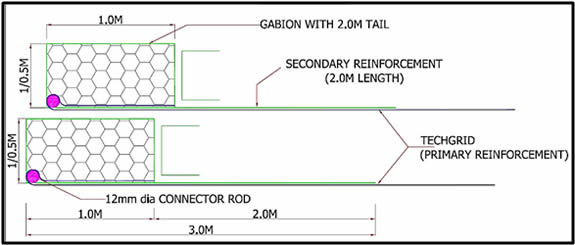

The geogrid panels were installed with the stone-filled metal gabions along with 12mm connector rods. U-pins were used to fix the position in the reinforcing zone.

The porosity of the gabion system allowed the dissipation of pore water pressure from the backfill material as and when required. A TechGeo Nonwoven Geotextile was installed to allow water to drain through while retaining the soil particles so as not to increase sediment load on the waterway.

PROJECT TAKEAWAYS

The composite system of the gabion fascia and reinforced soil wall produced a number of benefits for the Navi Mumbai International Airport construction:

- The composite system did not require the heavier or deeper foundation that a conventional retaining wall would have

- The permeable nature of the system guarded against hydrostatic pressure build up and uplifts from turbulent flow

- The flexible fascia enables the system to withstand some differential settlement without fracturing the structure, particularly when a structure is installed on unstable and uneven ground or in areas in which waterway conditions would otherwise threaten scour

- Vegetation was permitted to grow with the system, thus enabling it to blend into the natural environment

- The structure was more cost efficient and faster and easier to construct than other rigid similar function structures that were considered (e.g., conventional concrete walls)

Namrata Bichewar is a Design Engineer at TechFab India Industries Ltd., India. Learn more about the company’s geosynthetic technologies, engineering expertise, and global presence at www.techfabindia.com.