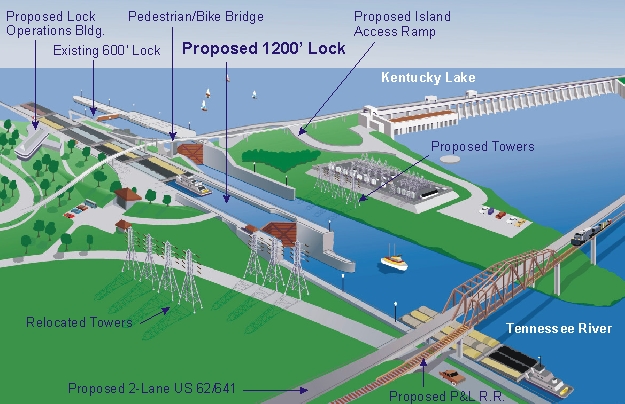

The Kentucky Locks Addition story began when the United States Army Corps of Engineers, in conjunction with the Tennessee Valley Authority, recommended an additional lock be built adjacent to the existing lock located at river mile 22.4 on the Tennessee River, at Kentucky Lake Dam, in western Kentucky. US62/641 and a section of the P&L Railroad currently carry vehicular and rail traffic across the crest of the earthen Kentucky Lake Dam. The roadway and railroad will require relocation to the downstream side of the dam in order to expand the lock.

As is common with earthen dams, a drain was installed near the down-stream toe of the dam as part of the original construction in the 1930’s. This presented a design challenge for the roadway relocation project in that the new highway embankment would have to cross over the existing toe drain. In the area to be crossed, a portion of the toe drain is constructed of vitrified clay pipe and a portion is constructed of reinforced concrete pipe. With embankment heights approaching 30 feet, stresses would be induced on the foundation soils beneath the embankment causing significant settlement of those soils and the toe drain pipes. Based on the magnitude of the estimated settlements, the Design Team identified concerns regarding the functionality of the toe drain system under full-height soil embankment loading. Because of the location of the toe drain, excavation and replacement of the pipe was not a practical option. In addition, any pipe replacing the existing pipe would still be subject to the same settlements and functionality concerns. The challenge then was to build a 30 foot tall embankment across the pipe without subjecting it to unacceptable settlements.

Fuller, Mossbarger, Scott and May Engineers, Inc. (FMSM) of Lexington, Kentucky, the geotechnical engineering sub-consultant for the roadway portion of the project, recommended a solution to the problem. Expanded Polystyrene Foam (Geofoam EPS) would be used as lightweight fill in the construction of a portion of the roadway embankment in the area overlying the toe drain. The Geofoam would be located over the toe drain area to reduce the stresses and associated settlements induced by embankment loads.

Geofoam EPS is an engineered thermal plastic material that is factory manufactured to exacting product standards. It has strength characteristics equal to a well-compacted soil fill, but with only 1 to 2 % of the weight of soil. Typical compacted soil fill is often estimated to have a unit weight of 125 pounds per cubic foot, while the Geofoam EPS specified by FMSM for the Lock Addition project exhibits a density of only two pounds per cubic foot. It is manufactured in large blocks that are easy to handle and install. A major benefit of Geofoam EPS is that it can be installed under any weather conditions. The Geofoam EPS was also capped by a geomembrane liner to protect it from hydrocarbon attack; in the event such a spill occurred. Standard construction techniques were permitted to take place over the installed Geofoam EPS subsequent to it being covered by soil embankment materials of sufficient depth.

The Contractor responsible for the Geofoam EPS installation and embankment construction at the Kentucky Locks Addition was Murry Paving. They installed the Geofoam EPS in 33" x 49.5" x 16 foot size blocks. The Geofoam EPS was installed by staggering the block layers and using a multi-barbed AFM Gripper plate to pin the layers together. The Geofoam EPS blocks were stacked to a maximum height of 160 inches and extended in plan for approximate dimensions of 850 feet by 48 feet. The project required a total of 2,600 Geofoam EPS blocks, equal to 17,000 cubic yards of fill.

An additional benefit of the Geofoam EPS used on the Lock Addition, was its insect resistance quality specified as Perform Guard EPS. Insect resistance of Geofoam EPS can be an important characteristic when the product is placed in ground contact in areas of the country where boring insects are found, such as termites. Termites do not use Geofoam EPS for a food source, but have been know to nest in foam insulations that can provide a safe, stable and non-toxic environment. Perform Guard termite resistant EPS prevents the potential for significant infestation which could diminish the structural capacity of Geofoam EPS.

For additional information on the Kentucky Locks Addition you can visit: www.orn.usace.army.mil/pao/kylock/default.htm

To learn more about Geofoam EPS you can visit:

www.geofoam.com