By Mathieu Cornellier – Natural gas extraction from shale formations has grown exponentially in the past few years in the United States, and all signs show that this trend will continue for the foreseeable future. The United States of America have one of the largest natural gas reserves which are contained in shale formations across the country. While recent advancements in horizontal drilling in hydraulic fracturing or fracking have enabled energy companies to extract the valuable resources at reasonable costs, many question the environmental impact of these processes.

By Mathieu Cornellier – Natural gas extraction from shale formations has grown exponentially in the past few years in the United States, and all signs show that this trend will continue for the foreseeable future. The United States of America have one of the largest natural gas reserves which are contained in shale formations across the country. While recent advancements in horizontal drilling in hydraulic fracturing or fracking have enabled energy companies to extract the valuable resources at reasonable costs, many question the environmental impact of these processes.

One of the main risks identified with these extraction methods is the contamination of the groundwater through jobsite runoffs. Solmax, a worldwide geomembrane manufacturer, is proud to say that it is doing its part to minimize the legitimate risk in these gas industries.

One of the main risks identified with these extraction methods is the contamination of the groundwater through jobsite runoffs. Solmax, a worldwide geomembrane manufacturer, is proud to say that it is doing its part to minimize the legitimate risk in these gas industries.

“The Added Benefits of PE Liners in Unconventional Gas Industries” (PDF)

Solmax has been working in the geosynthetics industry since its inception, in 1981. Solmax has distributed installed and manufactured geosynthetics for over 30 years. Today, Solmax’s mission is:

Solmax offers synthetic products used for separation and / or containment of solids and fluids in soil protection and water management applications. Intended for the construction, civil engineering and environment fields, Solmax’s products aim to improve the quality of life of individuals as well as our society’s well-being.

The experience gained by Solmax over the past 30 years has allowed it to offer the best containment products on the market. With these products, Solmax has been serving environmentally sensitive applications such as landfills, mining and the oil & gas. The valuable experience gained in these industries is not being applied to the Shale Gas industry.

Hydraulic fracturing or fracking requires large quantities of water. Water often needs to be stored on site prior to this event takes place as sources are not always within proximity of the wells being fracked. To contain this large volume of liquid, energy companies will either utilise in ground ponds or above ground tanks. The efficiency of these containment methods is important for environmental and economic reasons. While the fluid being contained is usually fresh water, leaks or spills of these containers might lead to large quantities of water spreading from the job site and into nature, carrying and leaching other products along the way. Water might also be a valuable

commodity in a given area and therefore, any leaks or spills might have economic repercussions on the operators.

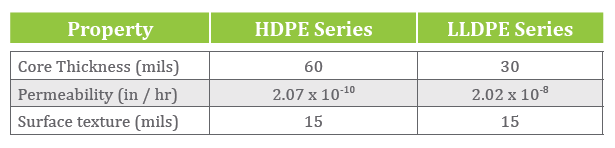

Therefore, the water containment system is very important and that is why, energy companies across the country rely on Solmax to supply them the optimal products for their primary containment needs. Depending on the containment method, two of Solmax’s geomembrane series are used for this application.

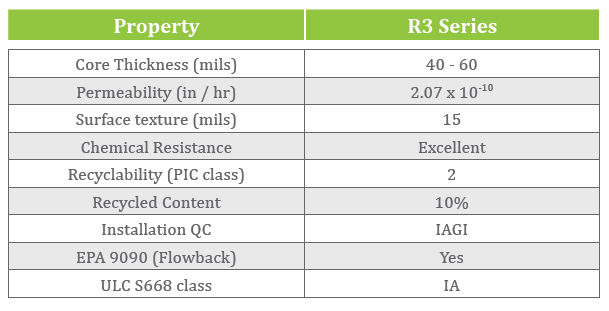

The second containment need within the shale gas industry is probably the most critical. Secondary containment during the drilling and fracking processes is very important. In fact, in most states, secondary containment is mandatory and regulated. Uncontrolled and uncontained runoff from the drilling and fracking pad represents one of the most probable risks of contamination of the water table. Solmax uses its gained experience in other industries to offer the optimal containment product for secondary containment. Solmax’s R3 Series is a liner that was specially developed for secondary containment in the Oil & Gas industry. It has a high coefficient of friction insuring a safe working area for workers, reducing the risk of slip and fall incidents. It is resistant to chemicals, hydrocarbon spills and puncture.

It is made of recycled content and is 100% recyclable. It is the only used liner in the shale gas industry to meet the ULC S668-12 class IA standard for secondary containment “Standard for liners used for secondary containment of aboveground flammable and combustible liquid tanks.”

Solmax has been working in the fluid and solid containment and management industry for over 30 years. It has and is still raising regulations in standards in environmentally sensitive industries for these applications all across the world. The shale gas industry is no exception to this. This industry is a young one and while not all parts of the processes are properly regulated, they are constantly changing to ensure that this valuable resource will be exploited efficiently and responsibly. With products such as the HDPE and LLDPE series for primary containment and the R3 series for secondary containment, Solmax is playing its part to make sure that, as its company mission states, “…to improve the quality of life of individuals as well as our society’s well-being” are taken care of.

**

Mathieu Cornellier is Technical Director at Solmax. Read more articles and access special application-specific magazines (e.g., Energy, Mining) at www.solmax.com.