Engineers at District 2 of the Illinois Department of Transportation were busy preparing plans for a major project in the Quad cities area in Rock Island County of Northwestern Illinois. The project, an extension of the Milan Beltway, was to include a long and highly visible drainage channel. The channel was built directly adjacent to the junction of the beltway extension and the busy John Deere Expressway in Moline, Illinois. The channel needed to withstand the stormwater runoff created by the large roadways. During storm events the channel needed to withstand velocities of 20 ft/s and shear stress forces reaching 13 lbs/ft2. Because of the high visibility of the project, the IL DOT wanted a solution that would permanently protect the channel, while still offering an aesthetically pleasing view for motorists.

Engineers at District 2 of the Illinois Department of Transportation were busy preparing plans for a major project in the Quad cities area in Rock Island County of Northwestern Illinois. The project, an extension of the Milan Beltway, was to include a long and highly visible drainage channel. The channel was built directly adjacent to the junction of the beltway extension and the busy John Deere Expressway in Moline, Illinois. The channel needed to withstand the stormwater runoff created by the large roadways. During storm events the channel needed to withstand velocities of 20 ft/s and shear stress forces reaching 13 lbs/ft2. Because of the high visibility of the project, the IL DOT wanted a solution that would permanently protect the channel, while still offering an aesthetically pleasing view for motorists.

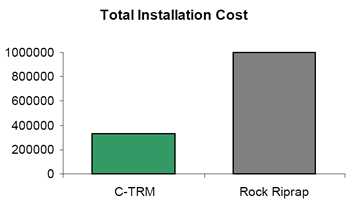

Initial plans called for a rock riprap channel lining with cost estimates for this solution totaling about one million dollars. In addition to obvious concerns about the high price tag, the engineers were also concerned about aesthetics and maintenance of a rock lined channel. For all these reasons, the IL DOT engineers sought out a vegetated solution for this project.

A VEGETATED SOLUTION

|

After several discussions with the District 2 Engineers, the suggestion of using the P550 permanent Composite Turf Reinforcement Mats was offered as an alternative to using rock riprap. After going through extensive designs using erosion control design software, the IL DOT chose to specify a high-performing composite turf reinforcement mat (C-TRM) for the Milan beltway extension project. The P550 is composed of a three-dimensional permanent netting structure, and also contains a permanent polypropylene fiber matrix. One of the main reasons they choose Tensar North American Green‘s P550 over other TRMs on the market, was that the CTRM offered both immediate erosion control protection as well as long-term vegetation reinforcement. Another reason for selecting the P550 C-TRM is because it is a surface applied product which does not require soil in-filling the product after installation. Because the P550 could be surface applied, the labor and installations costs were reduced. Additionally, this method did not create a sacrificial seed/soil layer that could be eroded when exposed to storm forces. By early the following year, the project was designed and bid, with initial construction set to start by the summer. After many delays, the majority of the C-TRM installation was completed in November, with approximately 20,000 square yards of product installed.

After the P550 was installed (top) the site experienced storm events that brought in unprotected debris (middle); just months later the P550 had established a fully vegetated channel (bottom).

TEMPORARY SETBACKS

The late installation of the TRM provided a real challenge for the project. Because the site would not have a chance to establish any vegetation prior to the winter months, dormant seeding was the only alternative. Since the seed would sit dormant all winter, and not start germinating until mid-spring, the bottom line was that the product itself, without the benefit of vegetation, was going to have to withstand any high flows that might occur throughout the winter months and into early spring. The area was seeded prior to matting installation with the Illinois DOT standard roadside mix which includes Kentucky 31 Fescue, perennial ryegrass, creeping red fescue, red top, as well as additional wetland grass species.

Complicating matters further was the fact that 20% of the project was not finished before winter set in, and that the 20% of the project unfinished was upstream from the TRM installation. This area, just north of the twin 10 foot by 10 foot box culverts that feed the main channel, was only protected by straws bale ditch checks for the winter. Periodic TRM inspections during the winter proved most satisfactory, with the P550 protected channel holding up very well. However, an extremely intense storm in late March put the newly installed channel to the test. This storm produced 3.5 inches of rain within one day creating flashflood conditions. Additionally, spring storms occurring only a few weeks later produced 2 in/hr rainfalls resulting in water several feet deep. During these storm events, the upstream temporary straw bale ditch checks blew out completely, but the turf reinforcement mat provided the necessary erosion control to protect the channel.

RESULTS

|

|

A site review in the spring concluded that the lined channel had performed exceptionally well, and that very few minor repairs would need to be made after the stormy spring season. Additionally, the site review concluded that the minimal damage to the P550 TRM installation was caused by the inadequate sediment control devices that were installed upstream from the site. As one engineer pointed out, the minimal cost of these repairs was dwarfed by the cost saving realized by the state. In comparison, the total cost of the P550 installation was less than one-third the estimated one million dollar rock riprap cost.

A site visit during the summer revealed a fully vegetated and functional drainage channel. The Illinois Department of Transportation was so pleased with the benefits of using turf reinforcement mats including cost savings, aesthetics, and function that they released a special provision allowing the use of surface applied composite turf reinforcement mats on department projects.

For more information about Tensar North American Green’s technologies and applications, visit www.nagreen.com or call +1 800 772 2040