By NAUE Geosynthetics – As part of the Deutsche Einheit (German Unification) Traffic Project 8.1, the Deutsche Bahn Netz AG (German Railways) ordered the construction of the Höhnberg and Füllbach tunnels on the Coburg-South section of the new twin-track line between Ebensfeld and Erfurt. The two tunnels cross one another with a vertical offset of 16m, which meant an enormous challenge for the tunnel design.

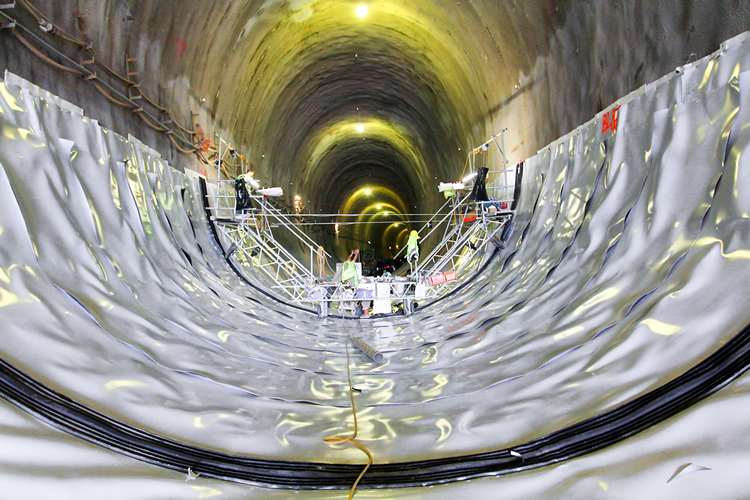

The all-round sealing, however, was “standard” in the best sense of the word. The structure and approach of the specialist installer Naue Sealing are a model example of a lining system capable of resisting hydrostatic pressure.

The Füllbach tunnel is 1,113m-long and designed as a single-track branch line for train speeds up to 130km/h. Just 16m above it, the 824m-long, twin-track Höhn tunnel carries ICE trains at up to 300km/h. The Höhnberg tunnel was the last of the 25 tunnels on the new line.

Environmental restrictions did not permit drained-tunnel construction, so all-round liners, impermeable under hydrostatic pressure (IHP), were utilized for both. The high quality results from the use of the NAUE products (complying with ZTV-ING and DB Directive 843.4101), and from the experience of NAUE SEALING as an installation specialist.

TUNNEL LINING DESIGN

The all-round liner structure is as follows (outside to inside):

- NAUE Secutex® R 1001-B2 ≥ 900g/m²

- 3mm Carbofol® Tunnel Liner, all-round

- Six-rib Carbofol® waterstops at the block joints.

- Carbofol® protection sheet 3mm at base

The Secutex® nonwoven is placed on the shotcrete and thus protects the geomembrane (Carbofol® Tunnel Liner) against mechanical damage. The protection nonwoven is attached using Carbofol® discs with proven predetermined breaking points. If the tunnel liner (GMB) is subjected to tensile stress during concreting, it pulls off the discs without being damaged.

The 3mm thick Carbofol® tunnel liner is the main component of the sealing system. It is installed as a single, tunnel-encompassing layer. It, too, is attached using Carbofol® discs with predetermined breaking points, and resists hydrostatic pressure. A white, light-reflecting signal layer on the inner face of the liner ensures good light conditions for the work underground and allows effective visual checking of the entire installed surface for damage.

NAUE Carbofol® tunnel liners are approved under both RIL 853 and ZTV-ING. They exhibit exceptional behaviour opposite high temperatures and aggressive liquids, bridge spontaneous cracking of the concrete structure without loss of functionality, are environmentally safe and extremely durable.

Six-rib Carbofol® all-round waterstops are welded on at the block joints. They fulfill several functions:

- Any damage is more easily localised

- Seepage is avoided

- The Carbofol® tunnel liner is protected from the head shuttering and the resultant concrete edge pressure

NAUE ensures that all components are produced with a compatible raw-material mix, so that homogenous welding is ensured between Carbofol® tunnel liners, protection layers, and waterstops.

On the tunnel invert, a 3mm thick Carbofol® protection layer is also used to protect the tunnel liner. This protection layer is welded to the waterstops to eliminate any leakage during concreting. After this, the concrete inner lining with a thickness of up to 60cm is installed.

The liner was installed during 2012/2013. A total of 80,000m² Secutex® protective nonwoven R 1001-B2, 80,000m² Carbofol® tunnel liner 3mm, 20,000m² Carbofol® protective layer, 6,000m Carbofol® waterstop SAA 600/6 and 190,000 Carbofol® discs were used. The tunnels are due for completion in 2014, and the route is scheduled to be operational in 2017.

For more information, visit www.naue.com.