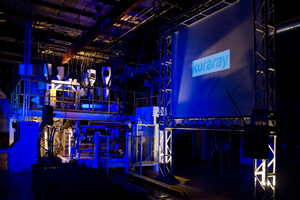

6 May 2011 – Kuraray’s EVAL™ group today dedicated its new Davis-Standard 7-layer cast coextrusion film and sheet lab line with a Cloeren NanoLayer™ feedblock and die at its Kuraray Research and Technical Center in Pasadena, Texas. The lab line provides leaders and innovators in industries as diverse as food and medical packaging, agricultural films, and building and construction with access to pilot scale lines as they seek ever-higher performance and cost efficiencies through the use of specialty materials.

6 May 2011 – Kuraray’s EVAL™ group today dedicated its new Davis-Standard 7-layer cast coextrusion film and sheet lab line with a Cloeren NanoLayer™ feedblock and die at its Kuraray Research and Technical Center in Pasadena, Texas. The lab line provides leaders and innovators in industries as diverse as food and medical packaging, agricultural films, and building and construction with access to pilot scale lines as they seek ever-higher performance and cost efficiencies through the use of specialty materials.

The result of an investment of more than $1,000,000, the lab line is equipped with five extruders and capable of producing cast film and sheet in thicknesses ranging from 1 mil (25 microns) to 60 mil (1,524 microns) in configurations of seven to 21 layers. The line also has full gravimetric control through a Davis Standard EPIC III™ control system.

As a result of this new capability, Kuraray EVAL’s existing and potential customers now gain access to innovative process technology and a pilot scale line tailored to produce model film and sheet structures for lab or field application testing. With Kuraray’s support during the design, development and validation process, film and sheet producers are able to create coextruded composites and measure critical performance barrier properties under a broad set of conditions.

“New market development with new technology is our mission as a pioneer of EVOH resin. We intend to enhance our technical service capacity as well as new market development by fully utilizing this new equipment,” said Mr. Kazuhiko Kugawa, General Manager EVAL Division, Kuraray Co., Ltd.

Complement to 7-Layer Blown Film Lab Line

The new line complements Kuraray’s ability to produce 7-layer blown film and multilayer PET/EVAL barrier containers.

“Our customers will enjoy the convenience of visiting one location that offers both blown and cast coextrusion pilot lab lines,” said Robert Armstrong, EVAL Director of Technical Service. “They will be able to complete tests of many different materials effectively and efficiently, with confidence in using process data from trials during scale-up. They will also benefit from the barrier and performance testing capabilities we have collocated with our process lab in Pasadena.”

Significant Interest from Customers

Armstrong continued: “We have received significant interest from our customers in the food packaging industry and from potential customers that produce agricultural films for soil fumigation and crop protection, or geosynthetic membranes for waste containment, brownfield remediation, and radon and vapor intrusion barriers. They are exploring ways to incorporate the Davis-Standard coex lab line into their testing and manufacturing processes. They have also expressed their intention to utilize the unique chemical, hydrocarbon and VOC barrier properties of EVAL EVOH in their products.”

About Kuraray EVAL™

Kuraray’s EVAL division manufactures and markets the world’s largest range of ethylene vinyl alcohol (EVOH) copolymer resins in the United States, Canada, Mexico and Central and South America. EVAL™ resins are characterized by their outstanding gas barrier properties; resistance to solvents, chemicals and hydrocarbons; and excellent barrier to odor and flavor permeation. These unique polymers are particularly suited for food, medical, pharmaceutical, cosmetic, agricultural and industrial packaging as well as automotive applications.

Contact

Kuraray Americas

Robert Armstrong

EVAL Director of Technical Service

+1 281 474 1576

Robert.Armstrong@kurarayamerica.com

http://www.kuraray.us.com