Two years ago, Leister Technologies AG debuted the GEOSTAR wedge welder line at Geosynthetics 2015, a biennial event. During the forthcoming edition (Geotechnical Frontiers 2017) in Orlando, Leister returns with a major advance for the GEOSTAR geosynthetic welding equipment: GPS-based, wireless seam data sharing.

Two years ago, Leister Technologies AG debuted the GEOSTAR wedge welder line at Geosynthetics 2015, a biennial event. During the forthcoming edition (Geotechnical Frontiers 2017) in Orlando, Leister returns with a major advance for the GEOSTAR geosynthetic welding equipment: GPS-based, wireless seam data sharing.

Geotechnical Frontiers 2017 will be held 12 – 15 March 2017 in Orlando, Florida. Leister will be in Booth #613.

GPS-BASED INSTALLATION DATA

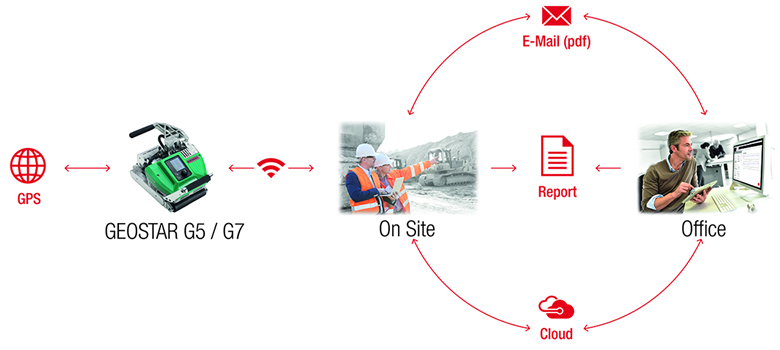

Geosynthetic installation equipment continues to evolve, enabling faster seam speeds without sacrificing geomembrane weld integrity. Leister has been on the forefront of these developments, and now the company is adding to its GEOSTAR G5 and G7 machines wireless data sharing as part of a geosynthetic installation quality system.

The GPS-based technology enables installers to record primary weld parameters and generate enhanced reports.

The Leister Quality System (LQS) is an app that runs in the background of the module. Benefits, noted in the initial information, include:

- Recording of weld parameters (speed, temperature and pressure)

- Recording of individual seam lengths, with start and stop time

- Easily identifies and locates weld anomalies via GPS position

- Easily adds seam number, roll number, technician ID etc.

- Data is easily transferable via Wi-Fi

“LQS is an entire solution,” says Thomas Furrer, head of Leister’s Geo business line. “It enables field personnel to communicate weld results directly with the office through the use of the LQS app.”

The LQS app is free to download and enables geosynthetics installation teams to manage up to 100 devices (welding machines) simultaneously. With the GEOSTAR units, the internal 8GB storage prevents data loss while storing data for more than 5,000 weld seams. Pre-defined reports are included, and the data can be incorporated into custom reports.

Leister will have product demonstrations during Geotechnical Frontiers 2017.

DOWNLOAD A LQA FLYER (PDF)

Learn more at www.leister.com.