By NAUE – Water gardens on Reden’s old mining area are sealed with Bentofix® X geosynthetic clay liners. This mining remediation project has helped revitalize an area of Germany long-in-need of attention. The place has quickly become a draw for tourism and new, more sustainble industries and economic development projects.

**

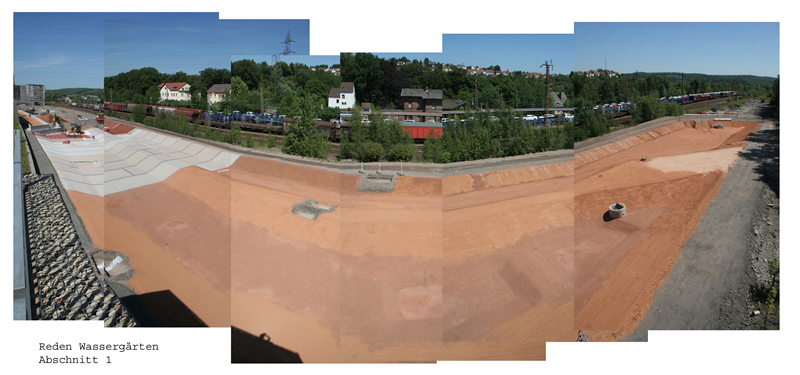

Waterfalls, sea roses, steel sculptures, a stream made seemingly of drifting fog – the water gardens at Landsweiler-Reden, Germany astonish visitors. Though miners once toiled there in bleak conditions, the site is now a place characterized by geothermal energy, tourism, extraordinary views, and recreation. The fantastic water gardens are a main attraction, and they have been made possible by an efficient sealing system of NAUE Bentofix® X2 BFG 5300 Geosynthetic Clay Liner (GCL).

Approximately 25,000 m² of GCLs have been installed.

The site of the water gardens is in the state of Saarland, a historical mining region. That legacy has left behind many industrial areas and other sites in need of care. In Reden, an organization known as the “Industrial Culture Saar” has executed some fascinating redevelopment projects—most notably, the water gardens.

The site was opened in 2012, an event that sought to “wake Sleeping Beauty.” The impact was immediate. Spectators were awed by how dramatically the landscape had changed. Indeed, the organizers had sought to use this site as a way to stimulate interest in other developments. All along, they had planned for this crowning water garden zone to be integrated into the larger region’s remediation and redevelopment of old mining operations. And for more than 10 years, as site by site was evaluated for its potential, they had dreamed of waking Sleeping Beauty here.

The site’s redevelopment used all available possibilities, with a major driving force to turn the necessities of the work into opportunities. For example, the water needed to be pumped out of the underground mines. This water was warm, so it was converted to a source of energy production. It was also used to create the “Fog Stream.” And since the site’s existing brownfields needed to be capped regardless, the redevelopment team used this as an opportunity to create rainwater and stormwater retention ponds.

A SECURE SEAL

The water gardens involve five connected ponds that branch out and incorporate different water levels. To have this elaborate, aesthetically-driven design over a sensitive site required a secure, long-term barrier system. It was a perfect application for the recently developed and introduced GCL Bentofix® X2 BFG 5300.

To act as a long-term barrier against many kinds of hazardous and chemical liquids—common on mining remediation sites—these Bentofix® GCLs have been engineered with an additional polyethylene (PE) coating. Bentofix® GCLs—also known as geosynthetic clay barriers (GBR-C)—are needle-punched, reinforced composites that combine two durable geotextile outer layers and a uniform core of high-swelling powder sodium bentonite clay. This construction forms a shear-resistant hydraulic barrier with self-sealing and re-healing characteristics. Additionally, the Bentofix® X series is coated with a durable and uniform polyethylene (PE) coating on the woven side, creating an additional low permeability barrier prior to hydration. It combines the benefits of bentonite and a PE coating in one multifunctional barrier system.

CRITICAL SUBGRADE PROTECTION

The subgrade throughout Reden’s old mining area and its railway network is very permeable. It is characterized by a mixture of old crushed rock from track beds, unknown fill material, contaminated soils and coarse grain soils.

In redeveloping the site and making the water gardens possible, the initial planning phase looked at using a 500mm-thick compacted clay as a seal. However, this sealing system would not have worked with the many known and anticipated penetrations and connections to structures, such as concrete stairs, pipes, foundations, old and new walls, etc. With Bentofix® X, the concerns were resolved. Batten strips secured the Bentofix® panels to structures and appurtenances to ensure firm seals throughout the system. To ensure that the PE-coated GCL was not damaged during installation, a needle-punched Secutex® R404 nonwoven was placed under and over the GCL. Since the subgrade material was expected to be very coarse in several places, the designers wanted to ensure that the bottom geotextile of Bentofix® would not be damaged. For this reason, Secutex® was laid under the Bentofix® GCL. Secutex® on top of Bentofix® protects the PE coating from being damaged during the cover soil placement process, as well as during the service life against any loads occurring from above.

The smart design and careful construction works ensured that the Bentofix®-based barrier system began its service life in optimal condition. And with the geotechnical and environmental protection issues taken care of, the awe-inspiring surface aesthetics were able to be developed.

Overall, 25,000m² of Bentofix® X2 BFG 5300 and twice that amount of Secutex® R404 were installed according to the following cross-section (from top to bottom):

- Pond beds with different types of vegetation

- Nonwoven protection geotextile, Secutex® R 404

- GCL, Bentofix® X2 BFG 5300

- Nonwoven protection geotextile, Secutex® R 404

- Leveling material for subgrade (aggregate 0/16 mm)

- Subgrade

For more information on geosynthetic clay liners (GCLs), visit NAUE: www.naue.com

RELATED

This YouTube video shows a bike ride through the redeveloped site. The transformation is impressive: