The new 2-step oxygen barrier from Raven Industries’ Engineered Films Division has been inspired, in part, from the company’s extensive work in gas barrier geosynthetics. It represents another multi-layer polymeric innovation from the Sioux Falls, South Dakota-based company. The new material (SealFresh™) is designed for the agricultural market and will serve primarily for silage cover operations.

The new 2-step oxygen barrier from Raven Industries’ Engineered Films Division has been inspired, in part, from the company’s extensive work in gas barrier geosynthetics. It represents another multi-layer polymeric innovation from the Sioux Falls, South Dakota-based company. The new material (SealFresh™) is designed for the agricultural market and will serve primarily for silage cover operations.

The 7-layer oxygen barrier’s production follows closely upon Raven’s announcement of its 7-layer cast extrusion manufacturing capability. The company has also made advances in equipment for flexible geomembrane production, polymer reclamation enhancement, and wide-width fabrication.

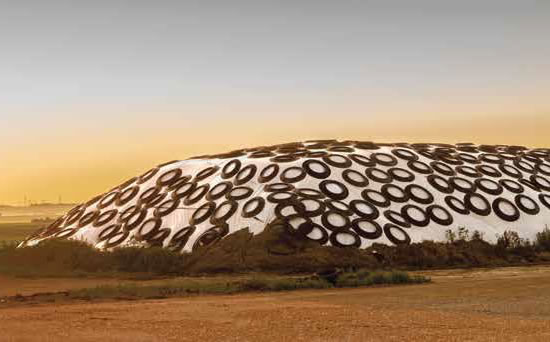

The new barrier material is a thin, 7-layer film used as the first step in a two-step design that prevents oxygen from reaching feed while preserving valuable nutrients. The base layer of the SealFresh™ oxygen barrier is placed directly against a pile, just below the primary exposed cover. It’s performance leads to peak fermentation conditions, the company’s writes, for forage stabilization and the reduction of dry matter loss.

The second component of the system is utilization of a Dura-Skrim® string-reinforced cover, which provides high UV resistance and long-term durability.

In a release on the new approach, the company noted the availability of an alternative outer cover called FeedPro-G, which offers a white/black non-reinforced option and which incorporates recycled resins in the core layer as an economical solution.

“Barrier technology contributes to the ultra-low oxygen transmission rate of SealFresh™ at 1.6 cubic centimeters per square meter per day,” Raven notes. “This equates to SealFresh™ blocking over 240 times more oxygen than traditional standard black/white plastic silage covers.”

AN OXYGEN BARRIER BUILT ON EXPERIENCE

The primary oxygen barrier is a flexible film, so it conforms to the pile configuration. It is also able to be delivered in an accordion-folded roll configuration for optimal deployment.

“We are excited to add a 2-step barrier to our silage cover lineup,” says Bart Brown, Director of Sales for Raven Industries’ Engineered Films Division. “SealFresh™ was developed in our research and development facility with proven results verified through extensive field studies.”

The oxygen barrier builds upon the company’s FeedFresh® Silage Cover (a reinforced 1-step cover) and adds to it Raven’s expertise in 7-layer gas barrier structures for the geosynthetics industry.

Learn more at www.ravenefd.com.