During the GAP 2019 transportation engineering conference, W. Jeremy Robinson, P.E. of the US Army Engineer Research and Development Center (ERDC) presented on work he and his ERDC colleague Dr. John Rushing, P.E. have been involved in. Here, we publish their paper on pavement preservation techniques from GAP 2019 and how to implement these practices in a pavement management system. ABOUT THE FEATURE IMAGE: Engineers John Rushing, Jesse Doyle and Jeremy Robinson of ERDC-GSL at Thule Air Base in Greenland. The photo comes from another project of theirs regarding continual paving operation inspection and the identification of deficiencies. Photo by Kevin Bjella.

Note: Funding for pavement preservation studies and policy implementation was provided by the U.S. Army Installation Management Command and the U.S. Air Force Civil Engineer Center. The methodology provided in this paper should serve as a guide for preservation and does not constitute endorsement of any material or supplier. Permission to publish was granted by the Director, Geotechnical and Structures Laboratory, ERDC.

1. INTRODUCTION TO PAVEMENT PRESERVATION

Environmental deterioration is a major factor leading to required rehabilitation of asphalt concrete pavements on airfields. Current design procedures used for airfields rarely lead to structural failures. In fact, Rushing et. al (2014) reviewed historical data from Army airfields and reported that only 5% of distresses existing in pavements ranging from 7 to 15 years old were load-related based upon pavement condition index (PCI) surveys. Meanwhile, the distresses related to environment-related degradation can cause large deductions in the PCI values. For example, the presence of medium-severity weathering over an area of airfield pavement can cause a PCI deduction of over 20 points (on the 0-100 point scale). The Department of Defense (DoD) mandates minimum threshold values for pavement condition, often leading to required maintenance resulting from environmental damage alone. Pavement preservation techniques are needed that can combat these types of distresses and maintain pavements in adequate condition for longer periods of time to reduce the overall life-cycle cost.

1.1 Background pavement preservation studies

Pavement preservation products have been commercially available for many years. Numerous reports document benefits and drawbacks of these products, including some by U.S. Army Corps of Engineer researchers studying methods to preserve airfield asphalt concrete pavements. Brown and Johnson (1976) studied five different asphalt rejuvenators during a period from 1971 to 1975. This study included field applications on three different Air Force bases in the southeastern, southwestern, and northern U.S. Target pavements were approximately 10 years old that had been free from maintenance. Test methods included skid resistance, penetration and viscosity tests on extracted asphalt binder, crack count, and surface texture analysis. Three of the five products decreased viscosity and increased penetration of the binder compared to untreated areas after three years, indicating softening of the binder was achieved. The same products reduced the number of cracks that were greater than 0.25 in. wide observed in the pavement. Further, all products reduced the loss of fines from the pavement surface, supporting the claims of reduction in environmental weathering. However, all products caused a decrease in skid resistance for a prolonged period of time (up to 2 years) which create the need to balance safety concerns with pavement life extension.

RELATED: Assessment of Historical Army Airfield Pavement Condition Data

Shoenberger (2003) performed a similar laboratory and field study on 16 rejuvenators, rejuvenator/sealers, and seal coats at two Air Force bases during a period of more than one year. Materials were characterized to determine the effects of treatment on extracted and recovered asphalt binder as well as the impacts on surface texture and skid resistance. These results supported those concluded by Brown and Johnson that some products did reduce asphalt binder viscosity from recovered field samples. However, most of these products reduced the friction of the pavement surface which continues to be the general consensus of researchers today.

Rushing (2009) provide information on usage and effectiveness of multiple types of pavement preservation products placed at DoD installations in the U.S. and Europe. While visual in nature, these inspections revealed inconsistent use of pavement sealer types at different installations and high dependency on the locally-available products. Navy researchers conducted a detailed field study from 2007 to 2008 to evaluate a gilsonite-based asphalt sealer at multiple locations throughout the U.S. (Cline, 2011). Results indicated improved life-cycle cost by using preventive maintenance treatments. Further, updates were recommended to Unified Facilities Criteria that would recommend or require the use of pavement preservation in pavement management.

In 2009 the U.S. Army Engineer Research and Development Center (ERDC) began a 5-year study on asphalt surface treatments for the Army to identify the best types of products for preserving pavements in good conditions. Field sites were selected on airfields at Fort Hood (Texas), Fort Benning (Georgia), and Fort Drum (New York) where fourteen different products were installed and monitored. Two years later the ERDC expanded on this study for the Air Force, applying nine materials on airfields at Davis-Monthan (Arizona), Dover (Delaware), and Hurlburt Field (Florida) Air Force bases for long-term observation. A comprehensive friction study during the initial curing period provided data for addressing safety concerns with these types of products. Since these controlled field studies, several DoD installations have performed large-scale treatment projects using different sealers. Runways at Edwards Air Force Base (California), Barking Sands Pacific Missile Range (Hawaii), the U.S. Air Force Academy (Colorado), and Naval Air Station Grotagglie (Italy) all have received asphalt surface treatments.

Continued monitoring of these test sites will provide data for adjusting policy guidance in the future.

1.2 Objective and scope

The objective of this paper is to present the methodology used to establish preliminary criteria for using preservation products on asphalt concrete airfield pavements and to implement this criteria into currently-used pavement management software. The criteria selected for identifying candidate pavements for preservation was created through consensus of pavement engineers within the DoD (Air Force, Army, Navy). The criteria was based upon identifying appropriate pavement condition, time between treatments, and required maintenance prerequisites. The scope of the project included any airfield pavements surfaced with asphalt concrete that are included in the routine pavement condition inspections performed by each respective agency. The PAVER software was used as the framework for implementation based upon its mandated use for managing the airfield pavement infrastructure.

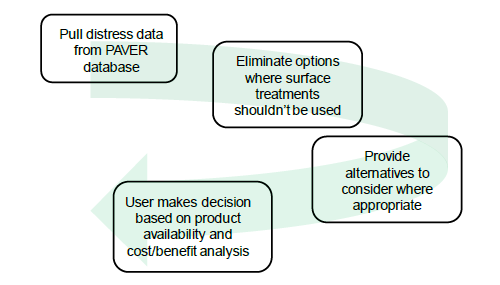

Criteria implementation was achieved by creating a module within the PAVER software that would review pavement inspection and construction history data and then screen these data according to the criteria. Multiple options for preservation treatment types may be identified in the process, requiring the user to balance cost and effectiveness given the local funding availability and pavement maintenance needs. Figure 1 illustrates the process by which the criteria is used within the pavement management software.

2. CATEGORIES OF PRESERVATION TREATMENTS

For the purpose of this paper, there are three categories of preservation treatments that are based upon their application method. These include liquid only sprays, liquid and sand sprays, and slurry-applied materials. The liquid only sprays are generally fog seal or rejuvenator products applied at rates commonly ranging from 0.05 to 0.1 gallons per square yard. Some are intended to penetrate the surface of the asphalt concrete and soften the binder while others serve to act as a surface barrier and binding agent. Liquid and sand sprays are those surface applications that include a mineral filler, that are applied at heavier rates (typically between 0.1 and 0.2 gallons per square yard), and that create a surface barrier over the pavement substrate. These materials may include fuel-resistant sealers as well. Finally, slurry-applied products provide a new thin wearing surface based on the gradation and shape of the aggregate in the slurry and the designed mixture.

3. DISTRESS EXCLUSION POLICY AND PRE-TREATMENT MAINTENANCE REQUIREMENTS

The overall procedure for selecting the appropriate type of surface treatment is based on a distress exclusion policy. This principle eliminates undesirable candidates from consideration based upon the presence of certain types, severity, and quantity of identified distresses. For example, alligator cracking is a common pavement distress that is caused by inadequate structural capacity. Preservation treatments are not effective at mitigating this type of distress, so the presence of alligator cracking above threshold values may result in a treatment type being excluded for consideration given that the pavement needs different rehabilitation strategies to improve the numerical PCI rating.

Each of the asphalt concrete distresses listed in ASTM D5340, Standard Test Method for Airport Pavement Condition Index Surveys, was assigned an exclusion value if applicable. Additionally, the exclusion values were based upon the severity of the distress. Using this method allows for the direct importation of field data into algorithms that screen the data for appropriate preservation treatments. This enables current software to provide recommendations. For pavement databases absent of certain distresses, the exclusion table can be bypassed.

Asphalt concrete distresses that did not influence the decision on using a liquid spray product included bleeding, low-severity block cracking, jet blast erosion, low-severity longitudinal and transverse cracking, patching, polished aggregate, raveling, low-severity swells, and weathering. For liquid and sand sprays as well as slurry-applied products, limitations were included on the presence of low-severity block or longitudinal and transverse cracking. These types of products were restricted because they would be less likely to fill the cracks and would be prone to having the cracks reflect to the surface. The remaining distresses contained an exclusion criteria for all product types.

Alligator cracking was limited to 5 percent for the total of all severity levels (low, medium, and high) and 2 percent for the area having medium and high severity. Being a load-related distress, alligator cracking is likely confined to the wheel path and only affects a portion of the pavement. Any persistent occurrence of this distress indicates structural capacity limitation and does not warrant the use of surface treatments, because rehabilitation is likely required.

Block cracking as well as longitudinal and transverse cracking were given an exclusion value for all product types if it occurred as medium or high severity. The threshold value for these types of cracking changed based upon treatment type. Because block cracking and longitudinal and transverse cracking are indicative of significant environmental deterioration, their presence greatly restricted the use of surface treatments. If the pavement binder has aged to the point where this type of cracking is occurring, it is unlikely that surface treatments will extend the usable life. Further, slurry-applied treatments may flake around reflected cracks and cause the risk of foreign object damage (FOD) to aircraft.

Corrugations and depressions were limited for all treatment types. It is unlikely that an airfield pavement section would experience large quantities of either of these distresses. However, if present, it would be difficult for either liquid sprays or slurries to be applied evenly. Ponding in the low spots of corrugated or depressed pavement could cause incomplete product curing that could lead to tracking of material.

Joint reflection cracking was limited to 10 percent total and 5 percent medium and high severity for all treatment types. Once this type of distress is observed, surface treatments are unlikely to limit its increase in quantity or severity. Cracks will propagate to the surface of the pavement and have potential to produce FOD. Asphalt concrete overlaying Portland cement concrete is often a poor candidate for pavement preservation because of the propensity for this distress to occur.

Oil spillage was given an exclusion value of 20 percent. Pavements experiencing greater than this quantity of oil spillage have likely endured significant binder damage. Additionally, surface treatments may trap unwanted oils in the pavement. Fuel-resistant sealers should be placed on airfield pavements prior to spillage occurring above this limit.

Rutting was restricted to prevent ponding of the surface treatments in the low spots of the pavement.

Rutting is not differentiated by its relation to asphalt mixture problems or subsurface structural issues. If it were asphalt mixture related, a surface treatment would not be desirable because it could keep the mixture tender for longer periods of time. The restriction for slurry-applied products was lower than for spray seals because a slurry type product can help to level the pavement surface.

Shoving was limited to 10 percent for all treatment types. It is unlikely that this distress would occur in greater quantities over a broad area, but if it did, the pavement could potential suffer from mixture issues that could be exacerbated by using a surface treatment.

Slippage cracking was limited to 10 percent of the total area. Except in the cases of an unusual event, the presence of slippage cracking is often indicative of horizontal shear failure due to lack of bond between pavement layers. Pavements exhibiting significant quantities of this distress should be slated for rehabilitation efforts.

Swells were limited to 20 percent for medium and high severity. While some surface deviations would not cause great concern, the presence of greater than low severity swells typically indicates significant frost action or swelling soils that need corrective maintenance.

RELATED: Evaluation of Geocell Reinforced Backfill for Airfield Pavement Repair

Pavements having distresses below threshold exclusion values were identified as candidates for preservation treatments. However, some maintenance is required prior to applying the surface treatment in many cases. Surface treatments are inherently limited by their ability only to address certain types of pavement distresses. Therefore, it is necessary to perform additional maintenance prior to their application to enhance effectiveness. Typical maintenance includes sealing medium- and high-severity cracking as well as patching. Each of the asphalt concrete distresses was reviewed to determine if maintenance should be performed prior to applying a surface treatment. For those requiring maintenance prior to applying surface treatments, the distress database from field surveys can be used to generate work plans based upon the quantity of the subject distress reported.

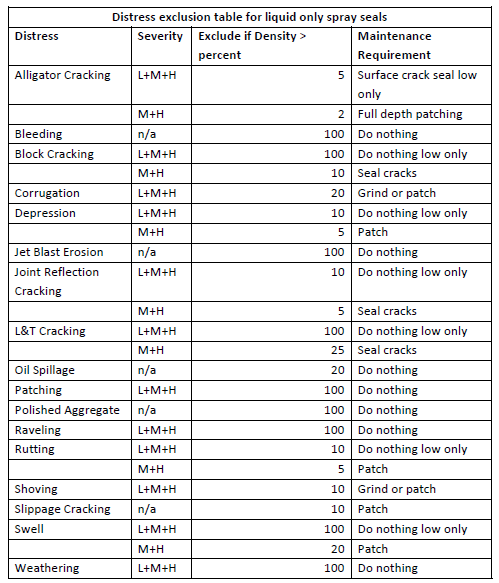

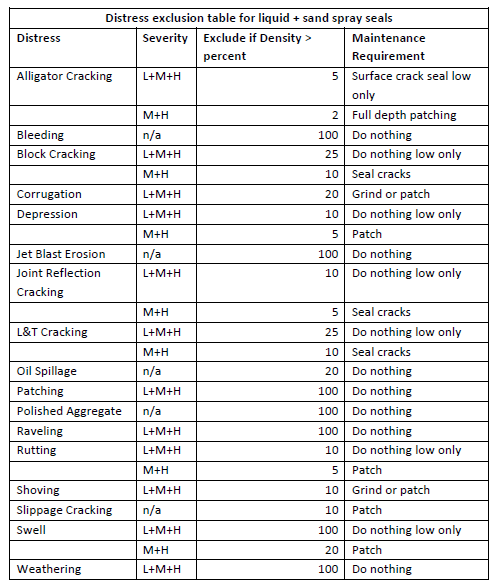

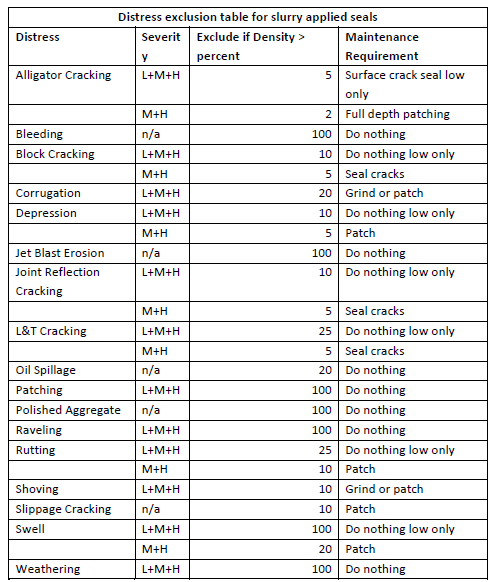

Table 1 provides the distress exclusion table and pre-treatment maintenance requirements for liquid only spray seals. Table 2 provides the requirements for liquid and sand spray seals, and Table 3 provides the requirements for slurry-applied products.

* L = low; M = medium; H = high; n/a = not applicable (no severity levels associated with distress)

* L = low; M = medium; H = high; n/a = not applicable (no severity levels associated with distress)

* L = low; M = medium; H = high; n/a = not applicable (no severity levels associated with distress)

4. IMPLEMENTATION INTO PAVER

PAVER is the DoD’s software system used for pavement management. One function of PAVER is to create PCI reports based upon user input of distress types, severity, and density in accordance with ASTM D5340. Additional functionality of PAVER includes the ability to create work plans, cost estimates, and predicted future pavement condition reports. These functions allow owners to prioritize funding to ensure pavements meet minimum policy thresholds for rating condition and to schedule maintenance and rehabilitation efforts.

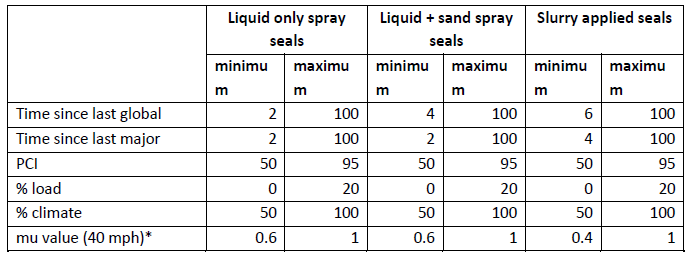

PAVER offers a direct implementation of pavement preservation criteria because reported individual pavement distresses are already housed within the database from the latest inspection. DoD policy requires all airfield pavements to be inspected periodically in accordance with the ASTM procedure. In addition to pavement distress data, PAVER also stores construction history data that can be used to guide users on appropriate timing between preservation treatments. The time between preservation treatments is based upon the type of material used to promote maximum effectiveness. While preservation treatments are most effective early in a pavement life, application frequency should be limited to prevent excessive buildup of material at the pavement surface. When available, pavement friction data can be used to ensure safety considerations are incorporated into the decision making process. Table 4 provides some overall pavement characteristics included in the criteria to guide users to the most effective implementation of a preservation strategy. These characteristics include the time since the last treatment (global) or overlay (major), the overall PCI, the percentage of distresses attributed to load or climate, and the pavement friction.

* Performed in accordance with method defined in Federal Aviation Administration Advisory Circular 150/5320-12, Measurement, Construction, and Maintenance of Skid Resistant Airport Pavement Surfaces

5. SUMMARY AND RECOMMENDATIONS

In summary, pavement preservation strategies can be effective at maintaining pavements in adequate conditions for extended periods of time. These strategies should be incorporated into overall pavement management programs to establish data-based policy for triggering the timing of such treatments. Using the PAVER software program, the DoD has established a methodology for users to evaluate an overall facility and to prioritize funding for preservation treatments. This procedure uses inspection data to screen pavement sections, to exclude those needing corrective maintenance or rehabilitation, and to establish overall pavement characteristics leading to the selection of an appropriate treatment type.

Coupled with the ability to forecast pavement condition and establish long-term work plans, pavement management using PAVER can be optimized by incorporating pavement preservation into a comprehensive pavement management program. The initial criteria reported herein should be routinely evaluated and adjusted based upon input from local installations. Selection of products used for preservation treatment should be based upon local material availability, cost, and past performance.

6. ACKNOWLEDGEMENTS

Funding for pavement preservation studies and policy implementation was provided by the U.S. Army Installation Management Command and the U.S. Air Force Civil Engineer Center. The methodology provided in this paper should serve as a guide for preservation and does not constitute endorsement of any material or supplier. Permission to publish was granted by the Director, Geotechnical and Structures Laboratory, ERDC.

ABOUT THE AUTHORS

Dr. John Rushing, P.E. and Jeremy Robinson, P.E. work for the U.S. Army Engineer Research and Development Center (ERDC). Learn more about ERDC’s work at https://www.erdc.usace.army.mil/.

REFERENCES

Brown, E.R. and Johnson, R.R. (1976). Evaluation of Rejuvenators for Bituminous Pavements. Report AFCEC-TR-76-3, Air Force Civil Engineering Center, Tyndall Air Force Base, FL.

Cline, G.D. (2011). Evaluation of a Corrosion Control Material for Asphalt Preservation of DoD Airfield Pavements. Technical Report TR-2363, Naval Facilities Engineering Service Center, Port Hueneme, CA.

Rushing, J.F. (2009). Field Evaluation of Asphalt Surface Treatment Usage and Performance. Technical Report ERDC/GSL TR-09-18, U.S. Army Engineer Research and Development Center, Vicksburg, MS.

Rushing, J.F., Doyle, J.D., and Harrison, A. (2014). “Significance of Non-Load Related Distresses on Airfield Asphalt Pavements: Review of 25 Years of Pavement Management Data,” Proceedings of the 2014 International Society of Asphalt Pavements, Raleigh, NC.

Shoenberger, J.E. (2003). Rejuvenators, Rejuvenators/Sealers, and Seal Coats for Airfield Pavements. Technical Report ERDC/GSL TR-03-1, U.S. Army Engineer Research and Development Center, Vicksburg, MS.