By Maccaferri – Crusher walls, also known as mine dump walls, are used to support vertical or near-vertical grade changes to minimize the footprint of the facility. Hoppers or crushers can be installed within these walls. Mined material is hauled to the upper terrace and unloaded into the hopper/crusher.

By Maccaferri – Crusher walls, also known as mine dump walls, are used to support vertical or near-vertical grade changes to minimize the footprint of the facility. Hoppers or crushers can be installed within these walls. Mined material is hauled to the upper terrace and unloaded into the hopper/crusher.

These large structures are part of the concentration facilities within the mine and crush the mined material to predetermined dimensions for further processing. The large haul trucks deposit the mined ores into the top of the crusher. Access to the top of the crusher and the maneuvering yard is provided by ramps and tall retaining walls.

Often MSE walls are used in this application. Reinforced soil is ideally suited to accommodate the high loads applied by the dump trucks.

DYER QUARRY

Dyer Quarry, Inc. is located in Robeson Township, Berks County, Pennsylvania. The facility is strategically located and serviced by Norfolk Southern Rail lines. Dyer also produces a wide variety of aggregate sizes meeting DOT (PA, NJ, DE, MD) and AAASHTO requirements. Such aggregates are mostly used in railway applications for their hardness.

A new primary crusher unit was being added to the Dyer Quarry in Birdsboro, Pennsylvania in 2014. The terrain at the design location for the new crusher was extremely challenging, a retaining wall was necessary to create a safe platform for unloading trucks.

SOLUTION

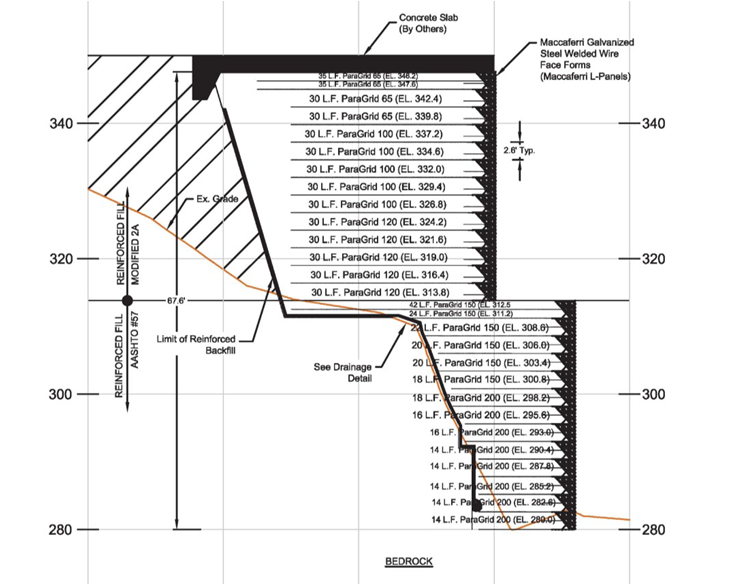

The Maccaferri MSE wall system, Parawall, was selected for its cost-effectiveness and efficient installation. Parawall is a welded wire fascia wall designed for this application. It features the following components:

- Fascia: Welded wire panels

- HDPE Net: Fascia stone retainer material

- MSE Wall Reinforcement: Paragrid 65, 100, 120, 150 and 200

- Drainage Composite: MacDrain W1051

- Geotextile: MacTex N35.1

The maximum exposed height of the Parawall is 70 ft with a wall fascia area of approximately 20,000 sq. ft. The Parawall is built around the crusher to minimize the lateral earth pressure on the crusher.

The wall is designed to support the live load of the haul truck (a CAT® D773) used at the facility. The haul truck’s payload exceeds 219,000 lbs. The Parawall provides the stabilized access platform.

Maccaferri Inc., working with Titan Engineering PC, provided engineering services for the design of these walls and Golder Associates built these walls in record time.

Additionally, Maccaferri coordinated the engineering services and material supply.

CONSTRUCTION AND MATERIALS

The wall shows several unique features and required special attention during the construction. Any field design changes (FDC) to the original submittal were documented and duly reported to the owner. As build construction drawings were also issued on the project’s completion.

It is interesting to note that the reinforced soil in bottom courses 1 – 16 was #57 stone while PADOT Modified 2A was used from course 16 – 28. The geosynthetic drainage composite MacDrain W1051 was installed between the modified 2A and the retained soil starting at the bottom of course 12.

It is interesting to note that the reinforced soil in bottom courses 1 – 16 was #57 stone while PADOT Modified 2A was used from course 16 – 28. The geosynthetic drainage composite MacDrain W1051 was installed between the modified 2A and the retained soil starting at the bottom of course 12.

The bonded geogrid (Paragrid) with tensile strength varying from 65 to 200 kN/m was used as an MSE wall reinforcement. Intermediate courses of Paragrid with tensile strength of 100, 120 and 150 kN/m were used to optimize the installed cost of the structure.

Paragrid consists of aligned arrays of high-tenacity polyester yarns encased in a thick protective sheath of linear low-density polyethylene (LLPDE). The LLDPE coating is more robust and durable against biological and chemical degradation which leads to unique performance in terms of long-term tensile strength and durability.

Each phase of the 12,950 sq. ft. project was completed ahead of schedule. Despite heavy rainfall throughout the construction phase of Courses 1 – 16, there were no recorded weather delays due to the selection of free-draining AASHTO #57 stone as the structural backfill.

For more reinforcement information and project stories, visit www.maccaferri-usa.com.

See also:

INDUSTRY PROFILE: Maccaferri