By Ian D. Peggs and Chris Kelsey – Low temperatures, fast-dropping temperatures, and strong winds can provide the ideal conditions for rapid crack propagation (RCP)—“shattering”—in exposed high-density polyethylene geomembranes. In the United States and Canada, winter weather patterns have become far less predictable, with “polar vortex” episodes, ice storms, and even tornado conditions followed by snow (as some areas of the US South experienced in January 2020).

Where temperatures reach atypically low levels, or when regions experience rapid fluctuations in temperature with cold temps involves, some risk may be posed to high-density polyethylene geomembranes if they are in an exposed state.

One threat that must be considered is rapid crack propagation, a phenomenon that can take a number of forms–many of which are dramatic–as a crack or cracks spread quickly through a polymeric material.

RELATED: Preventing HDPE Geomembrane Whales

What follows are some considerations about rapid crack propagation: how it may be exhibited on a geomembrane, potential risk points inspectors can identify, and considerations for moving forward.

RAPID CRACK PROPAGATION IN COLD TEMPERATURES

What are the ramifications?

Rapid crack propagation can occur instantaneously over several acres of exposed liner. Crack velocities have been timed at roughly 300 m/s.

What should you look for with respect to RCP?

Exposed HDPE geomembranes should be carefully monitored for short slow crack growth (SCG) stress cracks (the precursors of RCP) along the edges of extrusion welds, especially where they may have been overheated and where extrusion weld beads have been used to repair fusion welds.

Check patch welds on the liner side of the weld bead.

Can geomembrane stress cracking be eliminated altogether?

Probably not. But it can still surely be reduced if we understand its causes a little better.

We have made great improvements (specified NCTL times from 200 to 1000 hr) since the 1980s when there were extensive slow crack growth (SCG) and rapid crack propagation failures in exposed HDPE geomembranes. However, neither SCG nor RCP have totally gone away.

Meteorological conditions, such as those described at the opening, are one of the causes. Other causes might be manufacturers using recycled HDPE; insufficient carbon black in the formulations; insufficient S-OIT (under 10 minutes); or poor resins.

The manufacturing-related causes were largely eliminated after broad, field study and response in the late 1980s in North America and Europe to RCP phenomena. Many of those shattering incidents were connected to weather, such as rapid temperature decreases and uplifting winds.

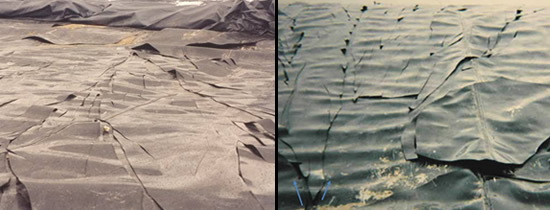

Some of these RCP failures were rediscovered in Asia in 2010. In these pictures, you can see strong visual correlation between a failure initiated by a rapid drop in temperature in the late 1980s and an RCP failure in Asia in 2010. The older failure initiated at an overheated section of a fusion seam that had been overlain by an extrusion bead.

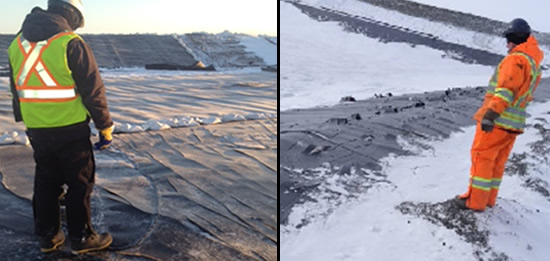

In the another pair of photographs here, you can see an SC failure along and close to a seam in an unreinforced polypropylene geomembrane on the slopes of a wastewater treatment plant (WWTP) and a nearly identical failure from another facility.

STRESS CRACKING SOLUTIONS

Rapid crack propagation can happen in spectacular fashion, but it is typically initiated at slow crack growth (SCG) stress cracks when they achieve a critical geometry and growth rate. An example of how this might be caused is through contraction stresses during rapidly decreasing temperatures.

If the SCG risk can be identified and repaired during routine visual inspections, rapid crack propagation can be avoided.

However, it is important to note that the primary solution is to ensure you specify high-quality geomembranes. In HDPE geomembrane design, this means use a virgin HDPE resin with good stress-cracking resistance and with adequate thermal and photo-oxidation resistances. The GRI-GM13 standard for smooth and textured HDPE geomembranes, used internationally, requires 2% to 3% carbon black for UV protection, stress cracking resistance exceeding 300 hr in the notched constant tensile load test (ASTM D5397), and OIT times exceeding 100 min (standard OIT) and 400 min (High Pressure OIT).

These quality control solutions from the best manufacturers give you the greatest defense against RCP and other stress cracking issues in the field. Following that, smart monitoring and CQA practices should be used to help you identify risk points and adequately protect or repair these zones.

THE TAKEAWAY

So, as long as polar air keeps vortexing, be pro-active! Climate change is changing how we must think of our infrastructure, how we design it, protect it, monitor it. We must adapt our inspection philosophy to enable facility owners and future designs to be more proactive.

Inspect your exposed liner for slow crack growth to minimize its progression and ward off the threat of rapid crack propagation and shattering.

Dr. Ian D. Peggs, P.E., P.Eng is the former president of I-CORP INTERNATIONAL. He retired from his corporate role in early 2020. Dr. Peggs remains open to communication from the field. Visit his website: www.geosynthetic.com.