Geosynthetics are used for a host of reasons, but economy, construction efficiency, and long-term performance (often linked to project economy) are frequently influential in the design and material selection process. Solmax has applied its extensive geomembrane experience to make geomembrane folds part of a highly efficient solution for geosynthetic installations.

Geosynthetics are used for a host of reasons, but economy, construction efficiency, and long-term performance (often linked to project economy) are frequently influential in the design and material selection process. Solmax has applied its extensive geomembrane experience to make geomembrane folds part of a highly efficient solution for geosynthetic installations.

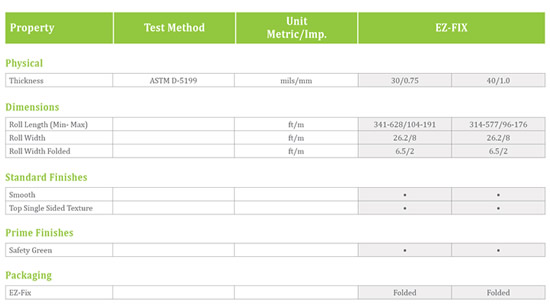

The new EZ-Fix Series a unique take on packaging for site delivery.

Many engineering professionals are familiar with the how pre-fabricated geomembranes can offer economy to a project. When flexible geomembrane panels can be fabricated in the controlled environment of a factory, a very large “single panel” can be created, put on a roll, and shipped to a site for rapid installation without nearly as much seaming to be done in the field.

The new EZ-Fix Series from Solmax draws upon that idea but extends it to smaller parcels. It takes 8m-wide rolls and folds them into 2m-wide rolls.

“Measuring 6.6 ft wide by a maximum 43 inches diameter and weighing in at a maximum of 2,800 lbs,” the company writes, “EZ-Fix rolls can fit in most heavy duty pick-up boxes.”

That feat makes delivery particularly convenient, especially to remote areas.

Solmax has spent considerable time working with its high-quality resin supplies and in its quality control and material development processes to ensure that the folding process does not alter the physical, mechanical, or endurance properties of EZ-Fix Series geomembranes. They, like other Solmax liners, meet or exceed all properties of the renowned GRI-GM17 standard.

It is this steady process of research, development, and change—for the better—that keeps the geosynthetics field growing.

Additional information on the EZ-Fix Series and other Solmax products is available through local representatives.

The company has released a video with a demonstration of an EZ-Fix roll being unfolded and deployed.

Learn more at www.solmax.com.