At the recent GRI-19 conference, concern was expressed by both a geomembrane manufacturer (Boyd Ramsey, GSE) and a CQA firm (Mark Sieracke, STS) about the consistency and specification of textured geomembrane – the general consensus being that asperity height is not sufficient to assure adequate interface shear properties.

Geosynthetic Engineering Concerns from a Manufacturer’s Perspective, authored by Boyd Ramsey, GSE Lining Technology

Geosynthetic Manufacturing Concerns from a Consultant’s Perspective, authored by Mark D. Sieracke, STS Consultants

Mark claimed textured geomembranes were not adequately consistent and that the material delivered to site might be quite different to that on which the design performance test had been carried out. He stressed that the manufacturer must make a consistent product to meet the intent of the design – and that many variables play into the design – that is why site specific testing is required. Manufacturers can’t control the adjacent materials-therefore they cannot control the performance characteristics with respect to these materials.

|

Boyd stated, and I believe this to be true, that the design engineer should be the one specifying the performance characteristics required and defining the type of textured/structured product required. Note that the term "textured" applies to randomly roughened products while "structured" applies to reproducible calendered surface profiles such as squared ridges and conical profiles, etc.

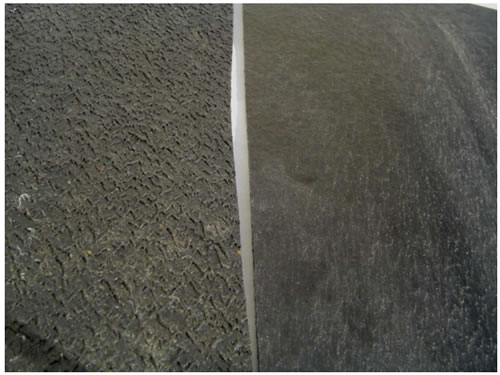

Although the consistency of textured geomembranes has improved, specifying roughness as a function of only asperity height (as the 10 mil in GRI.GM13) will never assure consistency in friction angle and interface shear strength. A rough angular peak, a smooth rounded peak, and a hooked peak will all have different interactions with a nonwoven geotextile for instance. And the height, geometry. and distribution will all interact differently with different sizes and angularities of different soil particles. Hence the reason that it is critical that shear tests be performed with the products and adjacent layers that are to be used in practice, and hence the reason for the concern about product consistency.

Clearly, not all textured materials are the same and there is no reason why a higher asperity height than GM13’s cannot be specified to achieve a higher friction angle. But, at the same time it must be recognized how difficult it is to characterize a randomly textured surface when asperity height, profile, and distribution are required. These parameters together with material tensile strength, modulus, and break elongation also define where the asperities will bend over, whether peaks break off, or whether the whole asperity breaks off, all of which, of course, will affect the measured friction angle. While the same parameters clearly affect the structured profiles, and it is necessary to select the appropriate profile for the interacting medium of concern, at least the structured profiles are consistent, at least within the same resin type.

The complexity of specifying random surface textures and the potential problems of using a single parameter do not make randomly textured products user-friendly, a concern that is often heard from engineers who would like to use all types of geosynthetics but are fearful of getting it totally right the first time. So, what can be done to make it more simple for such engineers and to encourage them to use textured geomembranes? There is no avoiding performing the ASTM D5321-02

direct shear performance test with the proposed product and actual field materials. At the same time, a simple tilting table shear reference test could be performed using the same geomembrane product and the appropriate adjacent field material at an appropriate confining pressure. The test conditions will not be defined here because they must be defined by the design engineer for the specific project. If the engineer is uncomfortable doing this he/should not be working on this project or should seek peer review assistance. A sample of the tested material should be retained for reference purposes.

When product is delivered to the site, the texture should be visibly compared with the reference sample, particularly for uniformity and distribution of roughness profiles. Asperity height should be measured as part of the CQA conformance testing. Another tilting table test should be performed by the design engineer – it is important that he/she acquire the experience and understanding of how interfaces perform. If there is any question about material consistency and ability of the surface to perform as required, full scale direct shear conformance tests should again be performed.

In any case, serious consideration of all available textured and structured materials should be given since all perform differently with different mating components. Select the products that will provide adequate technical performance and only then make a final selection based on price.

When working with enhanced friction geomembranes, whether randomly textured or reproducibly structured, the general philosophy of designing a geomembrane to be be a barrier only, and not a load-bearing member of the lining system (EPA/530/SW-91/054) should be borne in mind. This is particularly important when using HDPE with its susceptibility to stress cracking. When both sides of a geomembrane are textured and the friction angle on the top is higher than that on the bottom, stress is induced in the geomembrane. Friction enhanced materials are typically more susceptible to stress cracking than smooth materials. One way around this, of course, is to specify an HDPE with a higher stress cracking resistance than the GM13 specification of 300 hr. However, it should still be noted that, under higher-friction-on-top conditions, a slide above the geomembrane could result in tearing of the geomembrane. With lower-friction-on-top conditions the geomembrane will not be torn and barrier performance will be retained. Thus, there is a school of thought among experienced designers that the upper surface of a geomembrane should always be smooth and that the cover soil should be reinforced with a geogrid or a woven geotextile for veneer stability. This will provide more assured and more durable cover soil stability on slopes. Yes, it may cost a little more, but a negligible amount in compared to the whole project cost. Even better – what about a geomembrane/drainage/reinforcement composite!? The top geotextile of a geonet composite could be a high strength woven.

So, who is going to develop a geomembrane/geogrid or geomembrane/geotextile composite…?