The geosynthetics industry’s global growth has drawn the interest of an increasing number of market research organizations. Reporte’s latest analysis of the world geogrid market, Global Geogrids Market 2018, included a competitive analysis of 31 international companies. Canada-headquartered Titan Environmental Containment, which has been growing wildly in the past five years across many sectors and especially with its TE geogrids, appeared at number three on Reporte’s list.

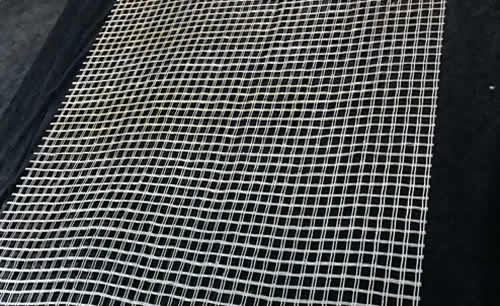

Diverse projects underscore the flexibility of their offerings in geogrid products. Key examples include this large mine haul road work featuring Titan’s TE-BXC Geogrid composite for soil reinforcement, drainage, and filtration, and this unique pedestrian sidewalk project using Titan’s innovative ConForce Grid as a steeless alternative in concrete reinforcement. That has much to do with the company’s growth.

DEVELOPING NEW TE GEOGRIDS

The inclusion of Titan high on the list is a nice recognition of the work the company has put in not just in the field but on the research and development side.

For example, two years ago Titan announced two key additions to its reinforcement materials portfolio: TE-FGP fiberglass and TE-FGC fiberglass composite geogrid systems for asphalt reinforcement applications. These new generation products feature an engineered polymer coating that enables the geogrids to endure higher temperatures, including remaining stable up to 900° F. The shrinkage rate is reported to be very low, as is the ultimate elongation properties—thus creating a rigid asphalt layer.

Sam Bhat (Vice President, Global Business Development and CTO of Geosynthetics) notes that the TE-FGC incorporates a nonwoven geotextile layer for additional waterproofing in the asphalt system, while the TE-FGP’s unique self-adhesive structure , optimal aperture size and unique engineered polymeric flexible coating ensures stronger surface bonding and within the asphalt layers and may eliminate the need for a tack coat.

These innovations are gaining deserved attention in the marketplace. They help reduce asphalt thickness and milling depth; enable faster installation; and enhance pavement service lives while reducing maintenance costs. Furthermore they reduce reflective cracking and surface rutting and greatly increase the fatigue life of the pavements.

Also of note on the geogrid side, Titan partnered with research, development, and commercialization specialist Applied Research of Australia (AROA) and introduced two geogrids for the mining market: TE-MXR PP and TE-MXR PET. In the partnership, Titan developed the grids and AROA developed the affiliated fiber-reinforced plastic (FRP) dowels as a non-steel solution soft rock and long-wall mining applications.

Learn more about Titan’s geogrids and global network at https://www.titanenviro.com. For inquiries please contact Titan’s Chief Technical Officer, Sam Bhat at: info@titanenviro.com or 1-204-878-3955 | 1-866-327-1957.