ATLANTA – August 5, 2013 – Tensar North American Green, the world’s leading provider of comprehensive erosion and sediment control solutions, is launching the VMax® W3000™ high performance turf reinforcement mat (HPTRM), which provides increased strength and protection for effective erosion control and maximum vegetation establishment.

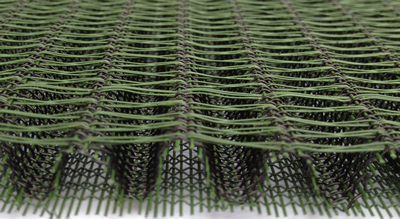

The VMax W3000 is the only multi-layered woven HPTRM on the market. The high strength, three-dimensional mat consists of a woven corrugated middle layer integrally interlaced into the woven top and bottom layers, which produces separate strata zones for both root and stem reinforcement.

“As an industry leader in erosion control solutions, we are responding to our customer’s needs by expanding our offerings and improving upon the proven VMax corrugated design,” said Tim Lancaster, Senior Regional Manager for Tensar North American Green. “With this addition, we’ve taken the opportunity to evaluate what is currently available in the marketplace to further enhance this multi-structural product that provides the greatest reinforcement to both vegetation roots and stems.”

The VMax W3000’s corrugated structure forms protective troughs perpendicular to water flow that function as check dams to capture and retain in-filled seed and soil. Other woven TRM products do not have these protective troughs, which results in more seed/soil infill resting on top of the mat instead of within the mat, creating an erosion-prone plane.

The VMax W3000 has an increased thickness providing an optimum open area for effective vegetation reinforcement and protection against high flow induced shear forces. The VMax W3000 also has very high tensile strength. The mat was tested to greater than 3000 lbs/ft tensile strength with 80 percent minimum tensile retention after 3000-hours of UV exposure. The increased tensile allows for greater bearing capacity of vegetated soils when subjected to heavy loads from maintenance equipment and other traffic.

Tensar North American Green conducted large-scale channel lining testing on the VMax W3000 HPTRM under stringent industry ASTM D6460 protocol. During testing, the vegetated VMax W3000 performed to the maximum level of the testing facilities’ capabilities and did not fail at flow induced shear stresses exceeding 13 psf and velocities over 24 fps. A testing summary that includes these impressive results is available upon request. With its quick and easy installation, and structurally sound vegetation reinforcement, VMax W3000 offers benefits to engineers, contractors and consumers alike while providing an aesthetically pleasing alternative to hard armored solutions.

To download a copy of the complete case study and learn more about the testing results, please visit: www.tensarcorp.com/north-american-green.

ABOUT TENSAR CORPORATION

Headquartered in Atlanta Tensar Corporation is a full-service provider of specialty products and engineering services that offer innovative and cost-effective alternatives to traditional construction methods. Tensar solutions are based on advanced soil reinforcement technologies and incorporate proprietary, engineered applications for commercial, industrial, municipal, residential and transportation infrastructure site development. The company specializes in solutions for common site development challenges, including grade changes requiring retaining walls and poor soil conditions affecting the cost of roadways, parking lots and building structures. Patented, polymeric Tensar® Geogrids and Tensar’s Geopier® foundation reinforcement piers, and various Tensar North American Green erosion control products, are the primary components of the company’s systems, offering reliable strength and durability. Contracted services include site evaluation, conceptual engineering, design, value engineering and installation advice. For more information, visit http://www.tensarcorp.com.