Ukraine has become a rising star in renewable energy, having opened to significant investment in solar and wind energy. Wind farms show particular promise. The EUR 1 billion+ Zophia Wind Farm in the south of the country exemplifies Ukraine’s vision for renewables. When it’s complete, it will be the largest onshore wind farm installation in Europe.

The site, which will ultimately include 160 turbines and produce 3,000 GWh to served more than 350,000 homes, is currently in Phase I of III for development. Significant geosynthetic reinforcement is being used to support the construction activity.

ZOPHIA WIND FARM REINFORCEMENT

It’s nearly impossible to construct wind farms without reinforcement now. The access roads must support massive loads for the turbine components and the cranes and construction pads needed to support the installation works. Hub heights for on-shore towers are essentially twice as tall as just 10 years ago and the energy output is more than 4 times greater. Rotor diameters regularly exceed 125m on new turbines.

RELATED: Geosynthetic Reinforcement for Wind Energy

For Zophia, Norway-based wind farm operator NBT is installing rotor diameter’s in the range of 145 m – 155 m and turbines with an average output of around 5 MW each, for a total output of more than 790 MW.

There are 11 onshore wind farms in the world with a greater output. All but three are in China, with two being in the United States and one in India.

Zophia is gigantic. The reinforcement need is great.

Machina TST, headquartered in Belarus and active internationally, is currently supplying a significant amount of geosynthetics to Zophia’s Phase I development (42.5 MW), which is to be completed by the end of 2020. Phases II and III, totaling more than 700 MW more, will follow in 2021.

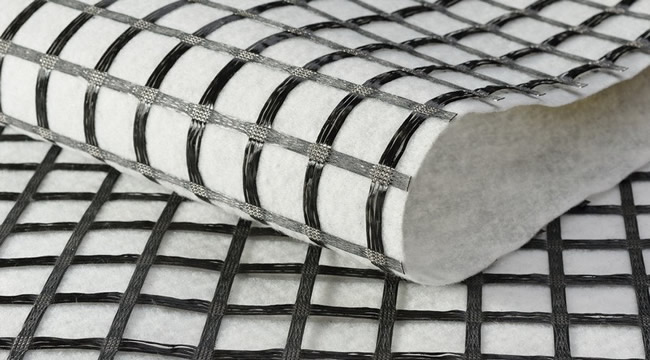

The company’s STRADEX geogrids and MULTITEX geogrid-geotextile composite reinforcement materials are being used to support the vast access road network that is making the extraordinary scale of construction on the site possible.

Efficiency is stressed in these road networks. A developer wants to minimize the amount of roadway to be constructed while avoiding having to use public roads as much as possible between turbines and during construction.

On the Zophia site, this will mean a very large road network. The site stretches roughly 39 km (24 miles) from its northern most point to its southern most.

Learn more about Machina TST’s geosynthetics and engineering applications at www.mahina-tst.com.